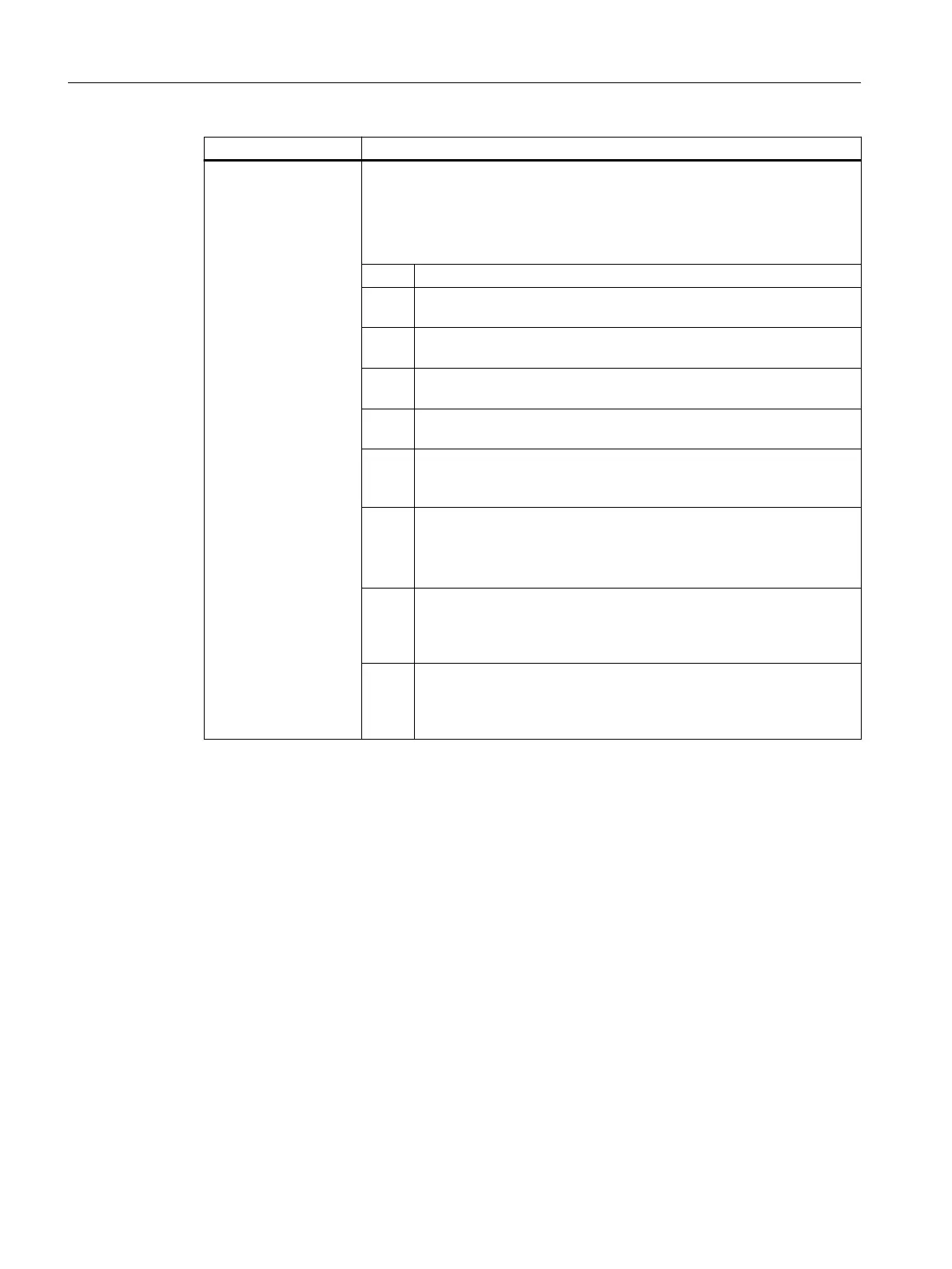

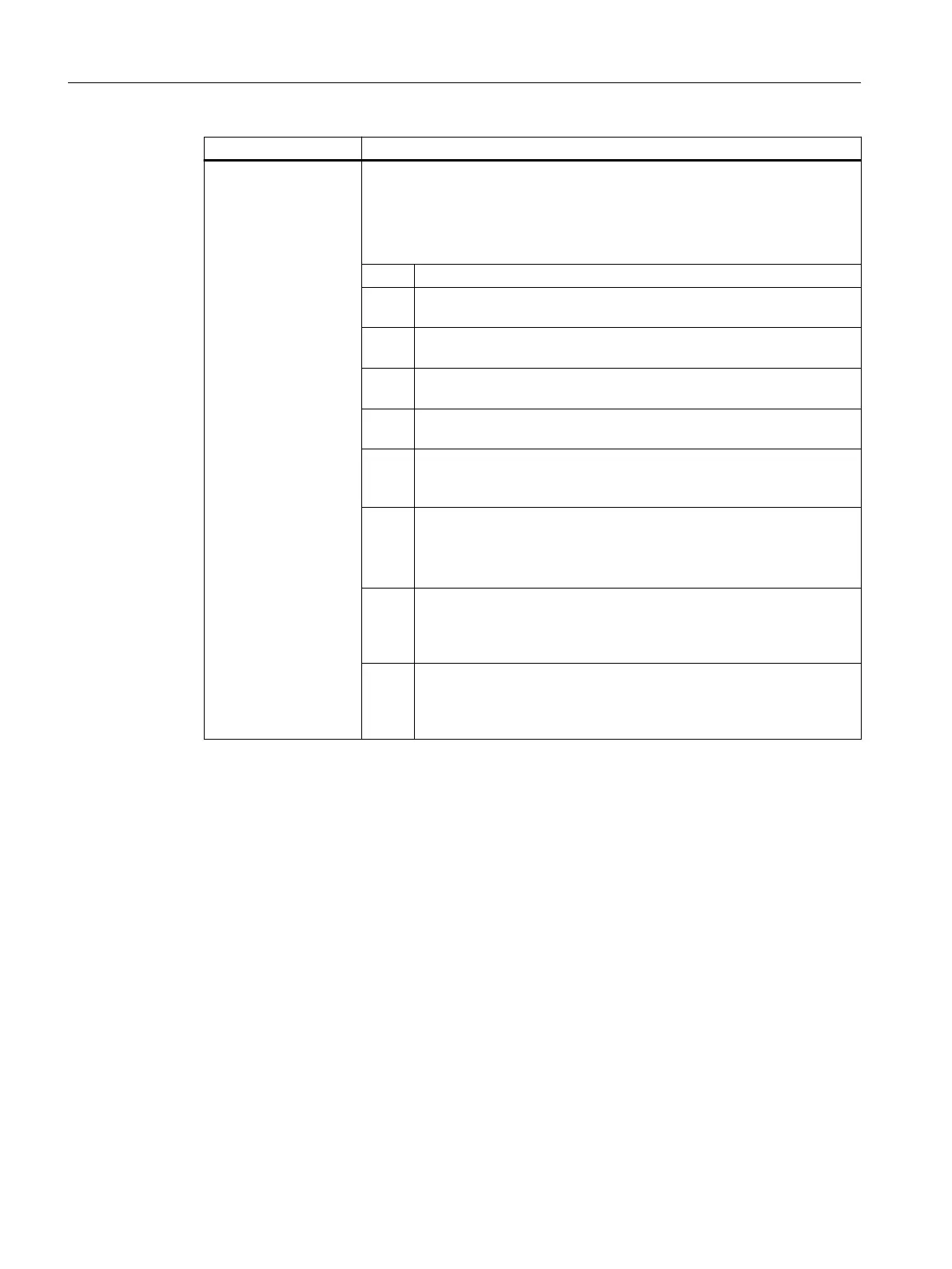

System variable Meaning

$P_CUTMOD_ERR Error state after the last call of the CUTMOD function

The CUTMOD function can also be called implicitly for a tool change. At a

reset, the variable is reset to zero. It is reset at every tool change and, if

required, rewritten.

The variable is bit-coded. The bits have the following meanings:

Bit 0: No valid cut direction is defined for the active tool.

Bit 1: The cutting edge angle (clearance angle and holder angle) of the

active tool are both zero.

Bit 2: The clearance angle of the active tool has an impermissible value (<

0° or > 180°).

Bit 3: The holder angle of the active tool has an impermissible value (< 0° or

> 90°).

Bit 4: The plate angle of the active tool has an impermissible value (< 0° or

> 90°).

Bit 5: The cutting edge position - holder angle combination of the active tool

is not permitted (the holder angle must be ≤ 90° for cutting edge po‐

sition 1 to 4; for cutting edge positions 5 to 8 it must be ≥ 90°).

Bit 6: Illegal rotation of the active tool.

The tool was rotated out of the active machining plane by ± 90° (with

a tolerance of about 1°). The cutting edge position is therefore no

longer defined in the machining plane.

Bit 7: The cutting plate is not in the machining plane and the angle between

the cutting plate and the machining plane exceeds the upper limit

specified with the setting data SD42998 $SC_CUT‐

MOD_PLANE_TOL.

Bit 8: The cutting plate is not in the machining plane. Angle α is greater than

1°. Angle α is the angle of rotation around the coordinate axis which is

perpendicular to the axis of rotation of angle β as well as to the axis of

rotation of angle γ (the X axis for G18).

$P_...: Preprocessing variables

$AC_...: Main run variables

All main run variables can be read in synchronized actions. A read access operation from the

preprocessing generates a preprocessing stop.

Plane change

To determine the modified cutting edge position, cutting direction and holder or clearance

angle, the evaluation of the cutting edge in the active plane (G17 - G19) is decisive.

However, if setting data SD42940 $SC_TOOL_LENGTH_CONST (change of the tool length

component when selecting the plane) has a valid non-zero value (plus or minus 17, 18 or 19),

its contents define the plane in which the relevant quantities are evaluated.

This priority rule of the setting data over the G code can be deactivated by setting bit 18 of the

machine data $MC_TOOL_PARAMETER_DEF_MASK. This means that when this bit is set,

the plane defined with the G command of group 6 is still valid.

Work preparation

3.13 Tool offsets

NC programming

804 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...