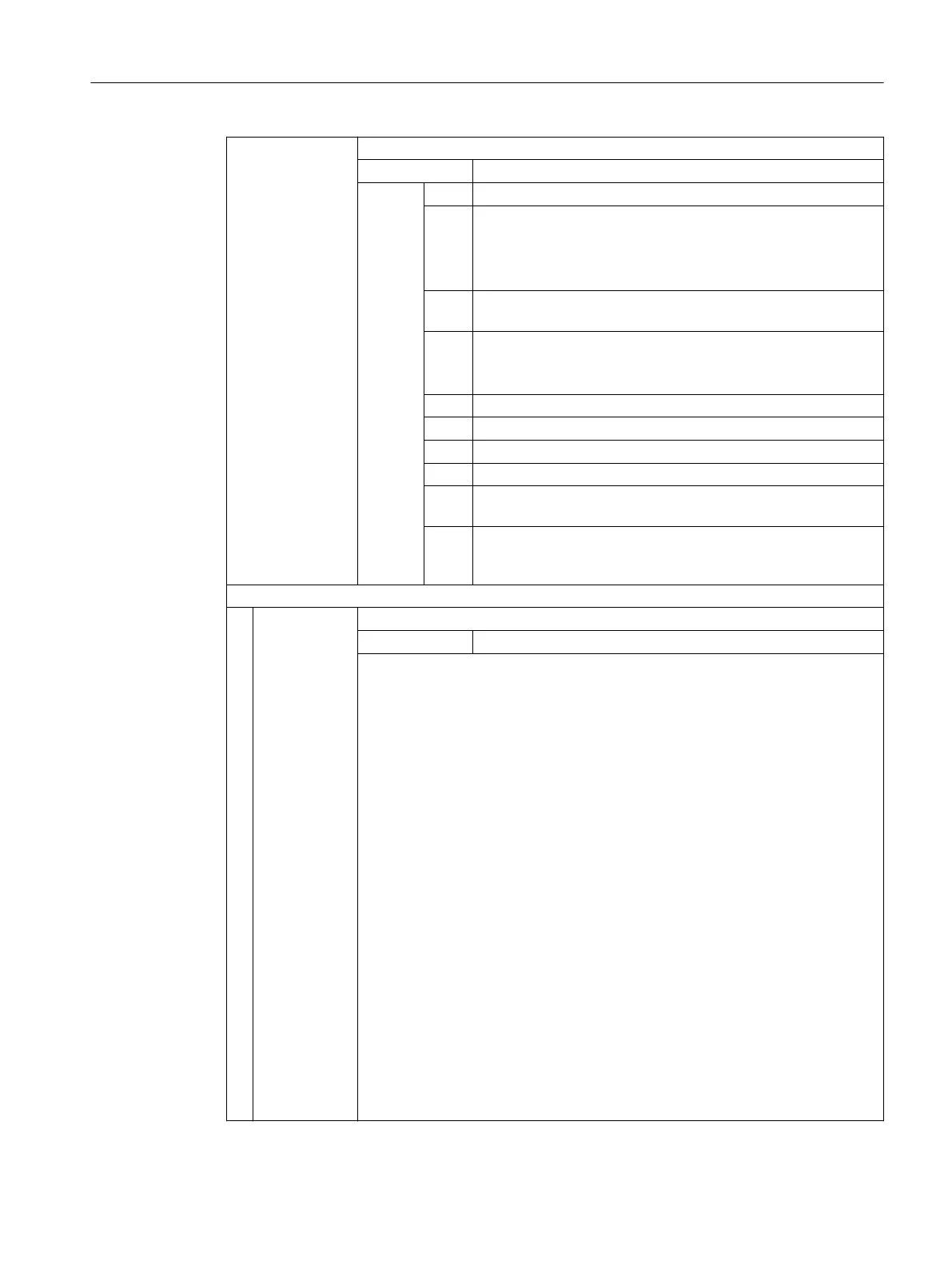

<Status>: Function return value. Negative values indicate error states.

Data type: INT

Value:

0 Function OK

-1 No memory reserved for tool environments:

MD18116 $MN_MM_NUM_TOOL_ENV = 0

This means that the "tool environments" functionality is not

available.

-2 A tool environment with the name specified under <Stat> does

not exist.

-3 Invalid string in parameter <Comp>.

Causes of this error can be invalid characters or characters pro‐

grammed twice.

-4 Invalid T number

-5 Invalid D number

-6 Invalid DL number

-7 Attempt to access a non-existent memory module.

-8 Attempt to access a non-existent option (programmable tool

orientation, tool management).

-9 The <Comp> string contains a colon (identifier for the specifi‐

cation of a coordinate system), but it is not followed by a valid

character denoting the coordinate system.

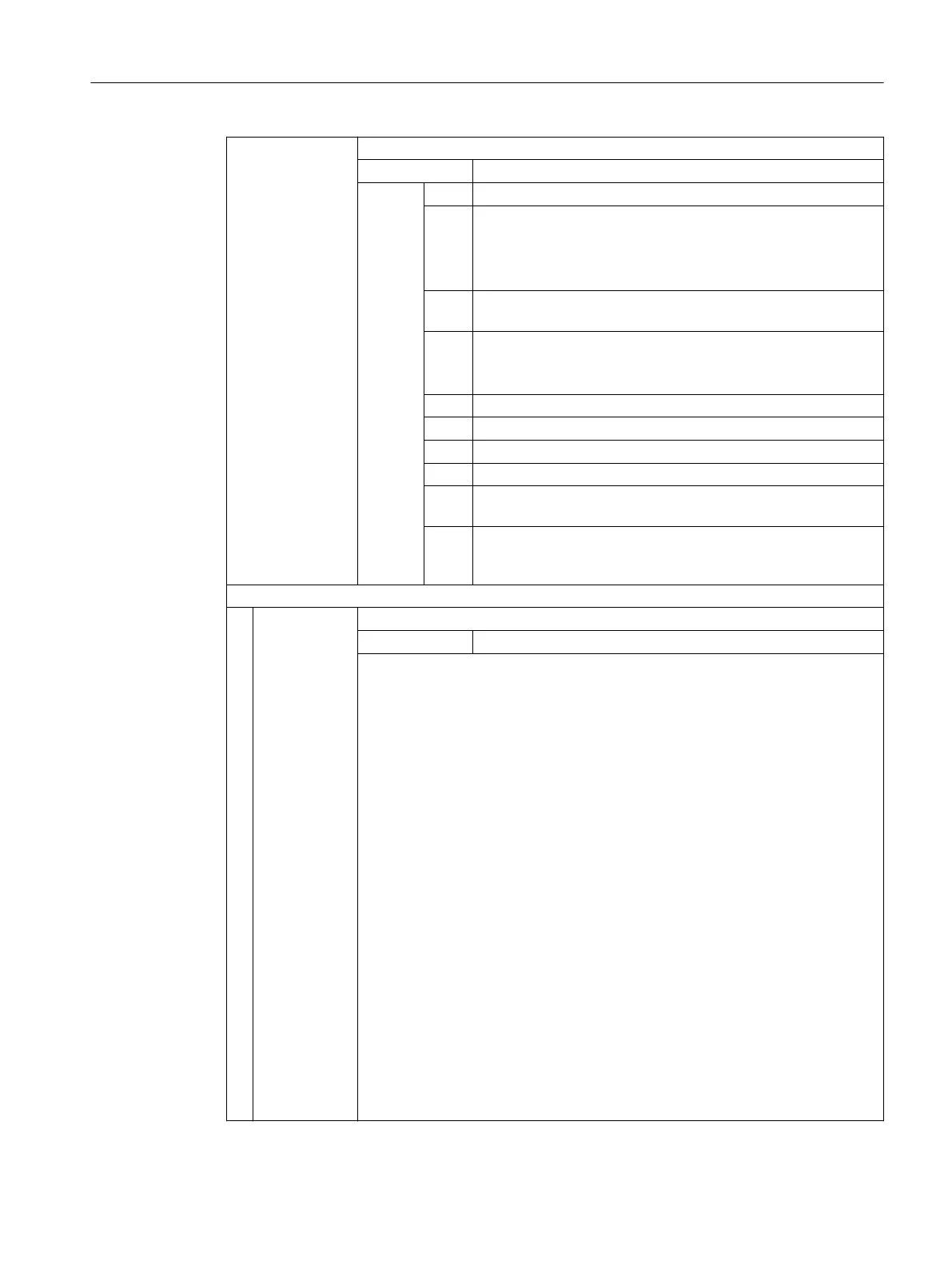

Parameters

1 <Len>: Result vector

Data type: REAL[11]

The vector components are arranged in the following order:

● <Len> [0]: Tool type

● <Len> [1]: Cutting edge position

● <Len> [2]: Abscissa

● <Len> [3]: Ordinate

● <Len> [4]: Applicate

● <Len> [5]: Tool radius

The coordinate system defined in <Comp> and <Stat> is used as the reference

coordinate system for the length components. If a coordinate system is not defined

in <Comp>, then tool lengths are displayed in the machine coordinate system.

The assignment of the abscissa, ordinate and applicate to the geometry axes

depends on the active plane used in the tool environment. This means, for G17, the

abscissa is parallel to X, with G18 it is parallel to Z, etc.

Components <Len>[6] to <Len>[10] contain the additional parameters, which can

be used to specify the geometry description of a tool (e.g. $TC_DP7 to $TC_DP11

for the geometry and the corresponding components for wear or sum and setup

offsets).

These 5 additional elements and the tool radius are only defined for components

E, G, S, and W. Their evaluation does not depend on <Stat>. The corresponding

values in <Len>[6] to <Len>[10] can thus only be not equal to zero if at least one

of the four specified components is involved in the tool length calculation. The

remaining components do not influence the result. The dimensions refer to the

control's basic system (inch or metric).

Work preparation

3.13 Tool offsets

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 813

Loading...

Loading...