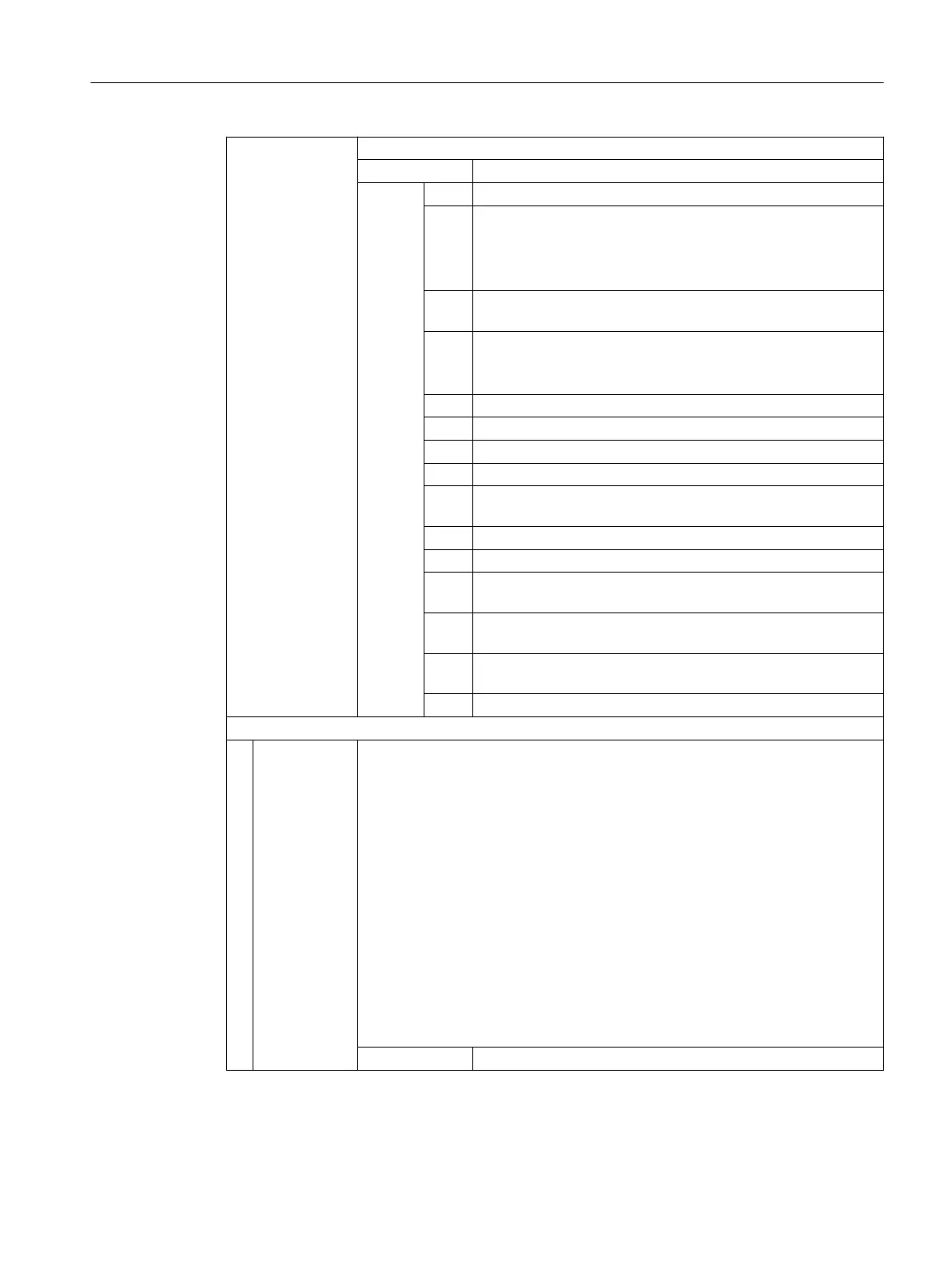

<Status>: Function return value. Negative values indicate error states.

Data type: INT

Value: 0 Function OK

-1 No memory reserved for tool environments:

MD18116 $MN_MM_NUM_TOOL_ENV = 0

This means that the "tool environments" functionality is not

available.

-2 A tool environment with the name specified under <Stat> does

not exist.

-3 Invalid string in parameter <Comp>.

Causes of this error can be invalid characters or characters pro‐

grammed twice.

-4 Invalid T number.

-5 Invalid D number.

-6 Invalid DL number.

-7 Attempt to access a non-existent memory module.

-8 Attempt to access a non-existent option (programmable tool

orientation, tool management).

-9 Illegal numerical value for parameter <CorComp>.

-10 Illegal numerical value for parameter <CorMode>.

-11 The contents of parameters <Comp> and <CorComp> are con‐

tradictory.

-12 The contents of parameters <Comp> and <CorMode> are con‐

tradictory.

-13 The content of the <GeoAx parameter does not designate a

geometry axis.

-14 Write attempt to a non-existent setup offset.

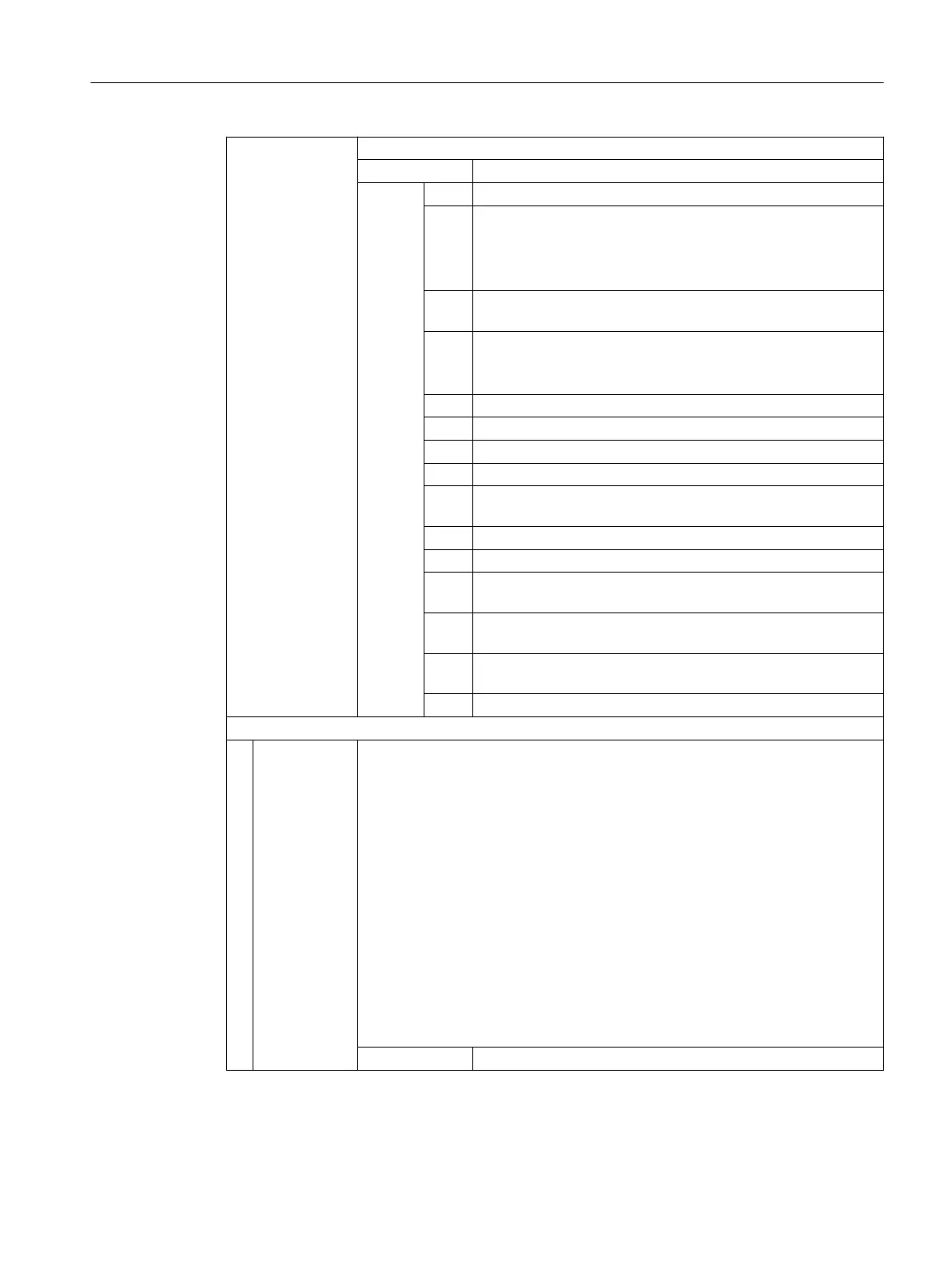

Parameters

1 <CorVal>: Correction vector

In the workpiece coordinate system (WCS) defined by <Stat>, the following as‐

signment applies:

● <CorVal> [0]: Abscissa

● <CorVal> [1]: Ordinate

● <CorVal> [2]: Applicate

If only one tool component is to be corrected (i.e. no vectorial correction, see

parameter <CorMode>), the correction value is always in <CorVal>[0], independ‐

ent of the axis on which it acts. The contents of the other two components are then

not evaluated.

If <CorVal> or a component of <CorVal> refers to the transverse axis, then the data

is evaluated as radius dimension. This means that a tool is, for example, "longer"

by the specified dimension; this correspondingly results in a change to the work‐

piece diameter that is twice as large.

The dimensions refer to the basic system (inch or metric) of the control system.

Data type: REAL[3]

Work preparation

3.13 Tool offsets

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 819

Loading...

Loading...