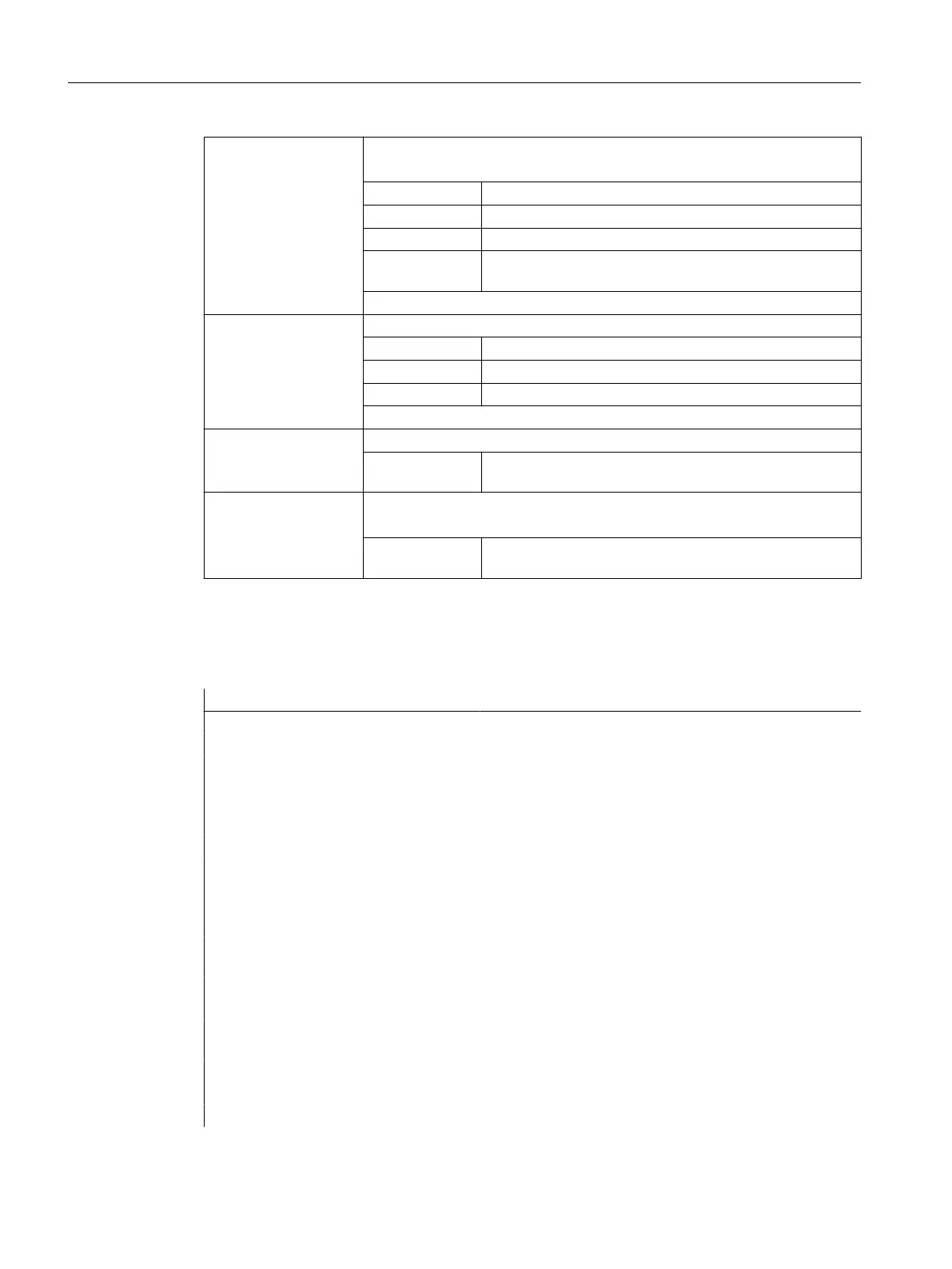

<block change>: Block change behavior

The block change is:

"NOC" Immediately

"FINE" On reaching "Synchronism fine"

"COARSE" On reaching "Synchronism coarse"

"IPOSTOP" On reaching IPOSTOP; in other words, after setpoint-

based synchronism (default)

The block change behavior is effective modally.

<coupling type>: Coupling type: Coupling between FS and LS

"DV" Setpoint linkage (default)

"AV" Actual value coupling

"VV" Speed coupling

The coupling type is modal.

<POSFS>: Angle offset between leading and following spindles

Range of val‐

ues:

0°… 359.999°

<POSFS>,<POSLS>: Switch-off positions of the following and leading spindles

"The block change is enabled once POS

FS

, POS

LS

has been passed"

Range of val‐

ues:

0°… 359.999°

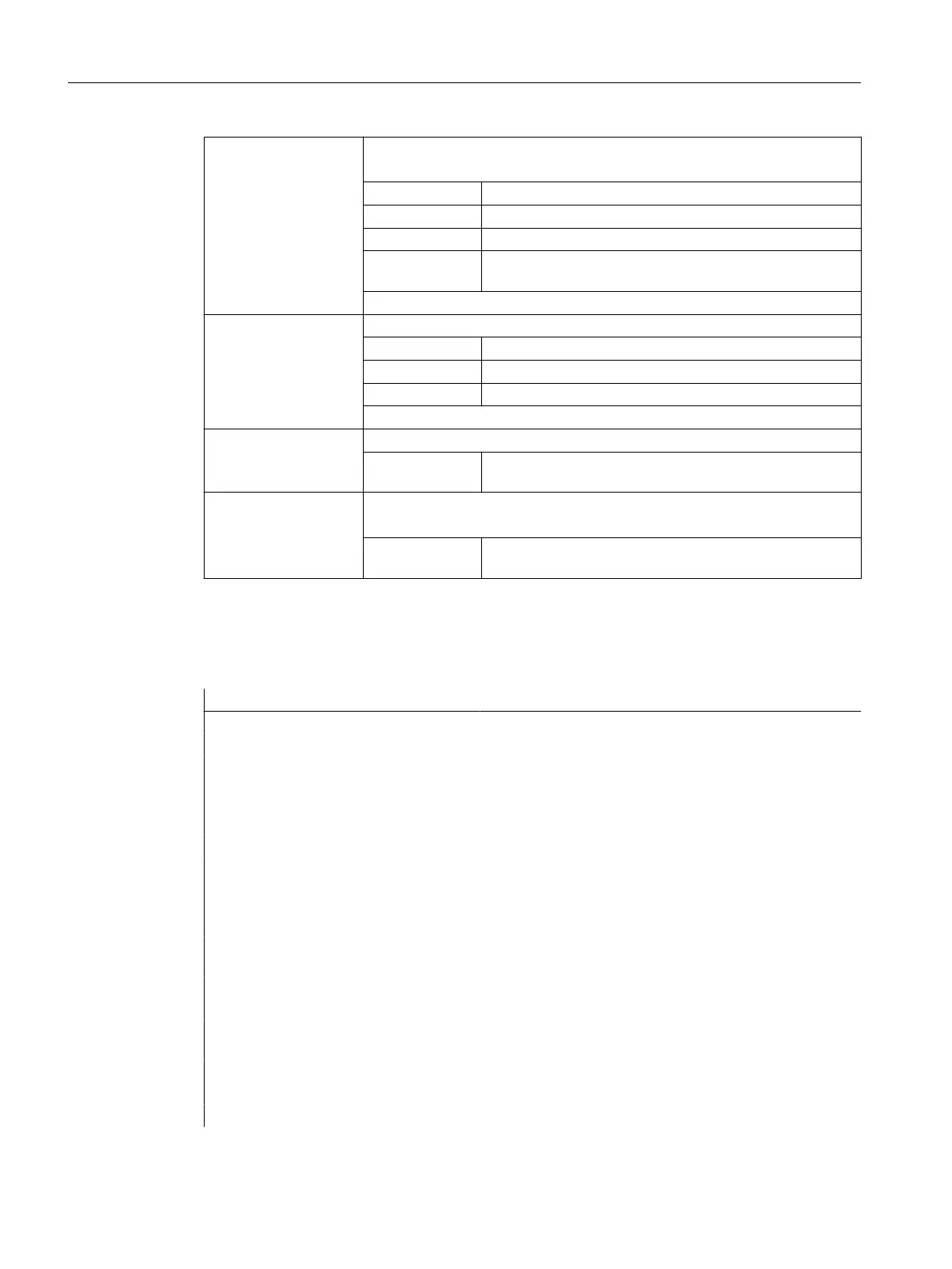

Examples

Working with leading and following spindles

Program code Comment

Leading spindle = master spindle = spindle 1

Following spindle = spindle 2

N05 M3 S3000 M2=4 S2=500 Leading spindle rotates at 3000 rpm,

following spindle at 500 rpm.

N10 COUPDEF(S2,S1,1,1,"NOC","Dv") Definition of the coupling (can also be config-

ured).

...

N70 SPCON Bring leading spindle into closed-loop position

control (setpoint coupling).

N75 SPCON(2) Bring following spindle into closed-loop posi-

tion control.

N80 COUPON(S2,S1,45) On-the-fly coupling to offset position = 45 de-

grees.

...

N200 FA[S2]=100 Positioning speed = 100 degrees/min

N205 SPOS[2]=IC(-90) Traverse with 90 degrees overlay in negative di-

rection.

N210 WAITC(S2,"Fine") Wait for "fine" synchronism.

N212 G1 X... Y... F... Machining

...

Work preparation

3.16 Axis couplings

NC programming

926 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...