Programming and Operating Manual (Turning)

102 01/2017

If you write M3 or M4 in a

block with axis movements

, the M commands become active

the axis movements.

Axis movements will only start once the spindle has accelerated to speed (M3, M4). M5 is also issued

before the axis movement. However, it does not wait for the spindle to stop. Axis motion already starts before the spindle

comes to a standstill.

The spindle is stopped with the end of the program or with the following key:

At the beginning of the program, the spindle speed is zero (S0).

Other settings can be configured via machine data.

N10 G1 X70 Z20 F3 S270 M3

; before the axis traversing X, Z the spindle accelerates to 270

r.p.m., clockwise

; Z movement, spindle comes to a stop

Spindle positioning

11.9.2.1

Spindle positioning (SPOS, SPOSA, M19, M70, WAITS)

Functionality

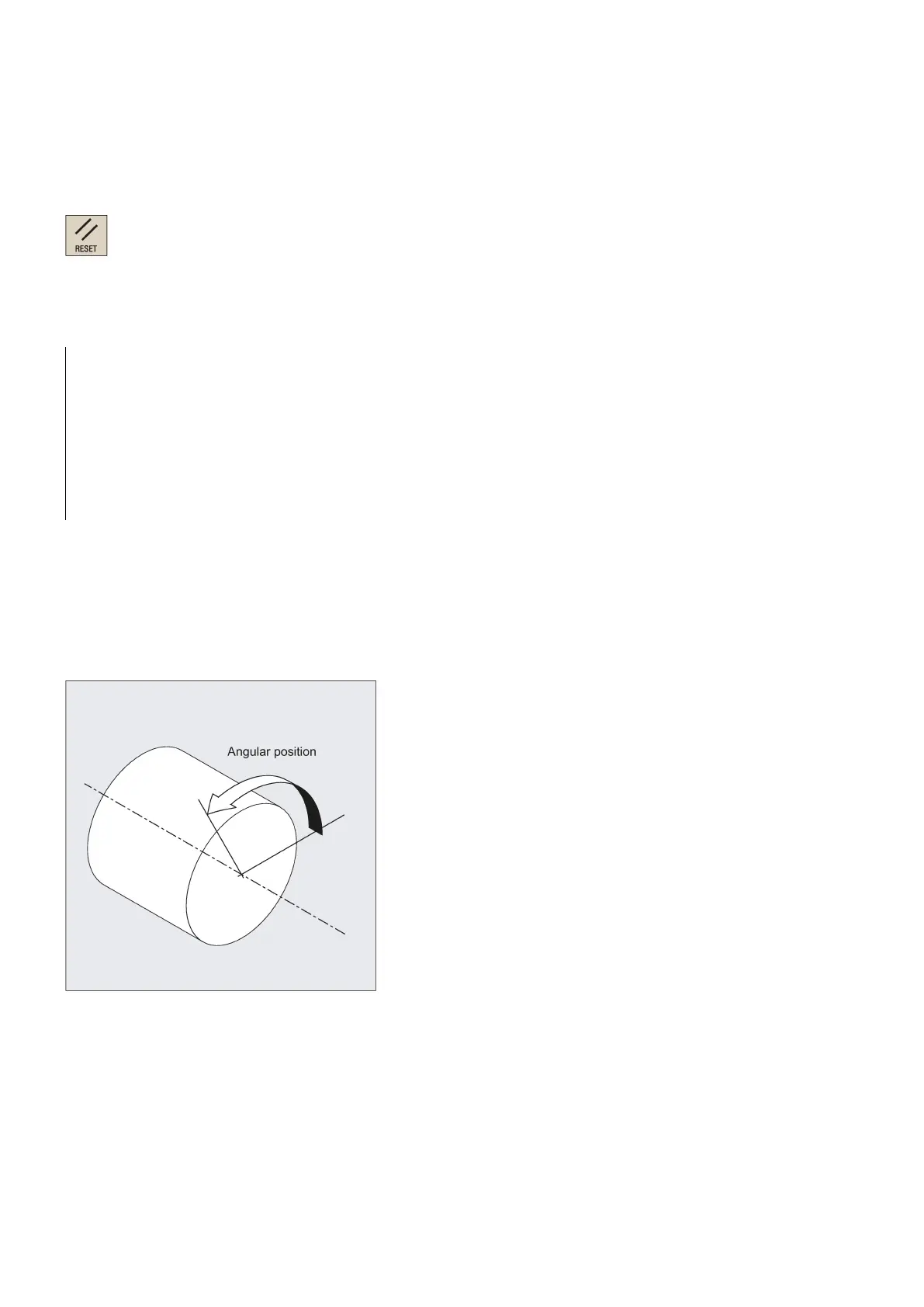

SPOS, SPOSA or M19 can be used to set the spindle to specific angular positions, e.g. during tool change.

SPOS, SPOSA and M19 induce a temporary switchover to position-controlled mode until the next M3/M4/M5/M41 to M45.

The spindle can also be operated as a path axis, synchronized axis or positioning axis at the address defined in the machine

data. When the axis identifier is specified, the spindle is in axis mode. M70 switches the spindle directly to axis mode.

The end-of-motion criterion when positioning the spindle can be programmed using FINEA, CORSEA, or IPOENDA.

Loading...

Loading...