Programming and Operating Manual (Turning)

200 01/2017

CON02_E:;************* CONTOUR ENDS ************

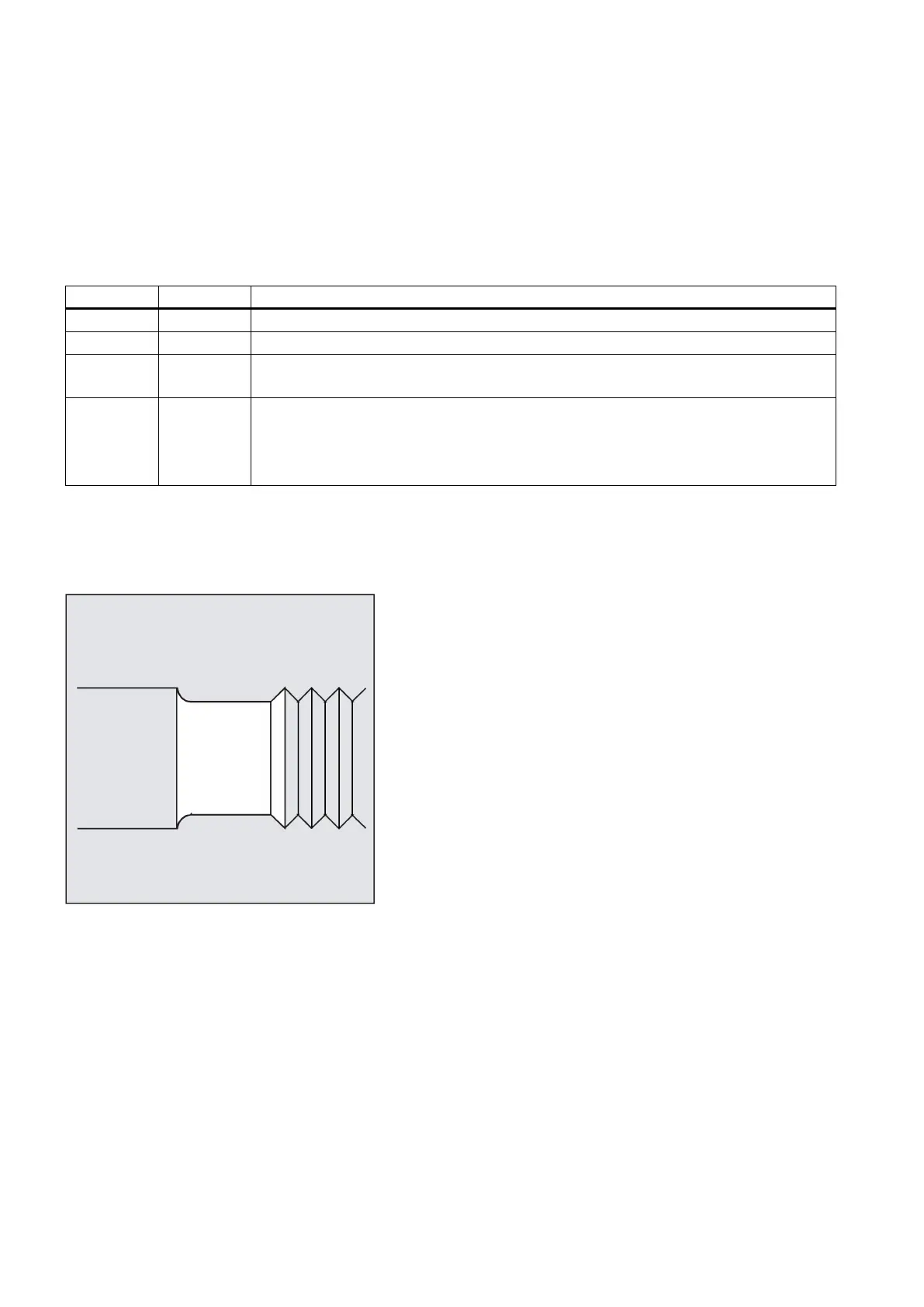

Thread undercut - CYCLE96

Programming

CYCLE96 (DIATH, SPL, FORM, VARI)

Nominal diameter of the thread

Starting point of the correction in the longitudinal axis

FORM CHAR Definition of the form

Values: A (for form A), B (for form B), C (for form C), D (for form D)

VARI INT Specification of undercut position

Values:

0: According to tool point direction

You can use this cycle to perform thread undercuts to DIN76 for parts with a metrical ISO thread.

See the following illustration for CYCLE96:

Sequence

Position reached prior to cycle start:

The starting position is any position from which each thread undercut can be approached without collision.

The cycle creates the following sequence of motions:

● Approach of the starting point determined in the cycle by using G0

● Selection of the tool radius compensation according to the active tool point direction. Traversing along the undercut

contour using the feedrate programmed before the cycle was called

● Retraction to the starting point with G0 and deselection of the tool radius compensation with G40

Loading...

Loading...