Programming and Operating Manual (Turning)

176 01/2017

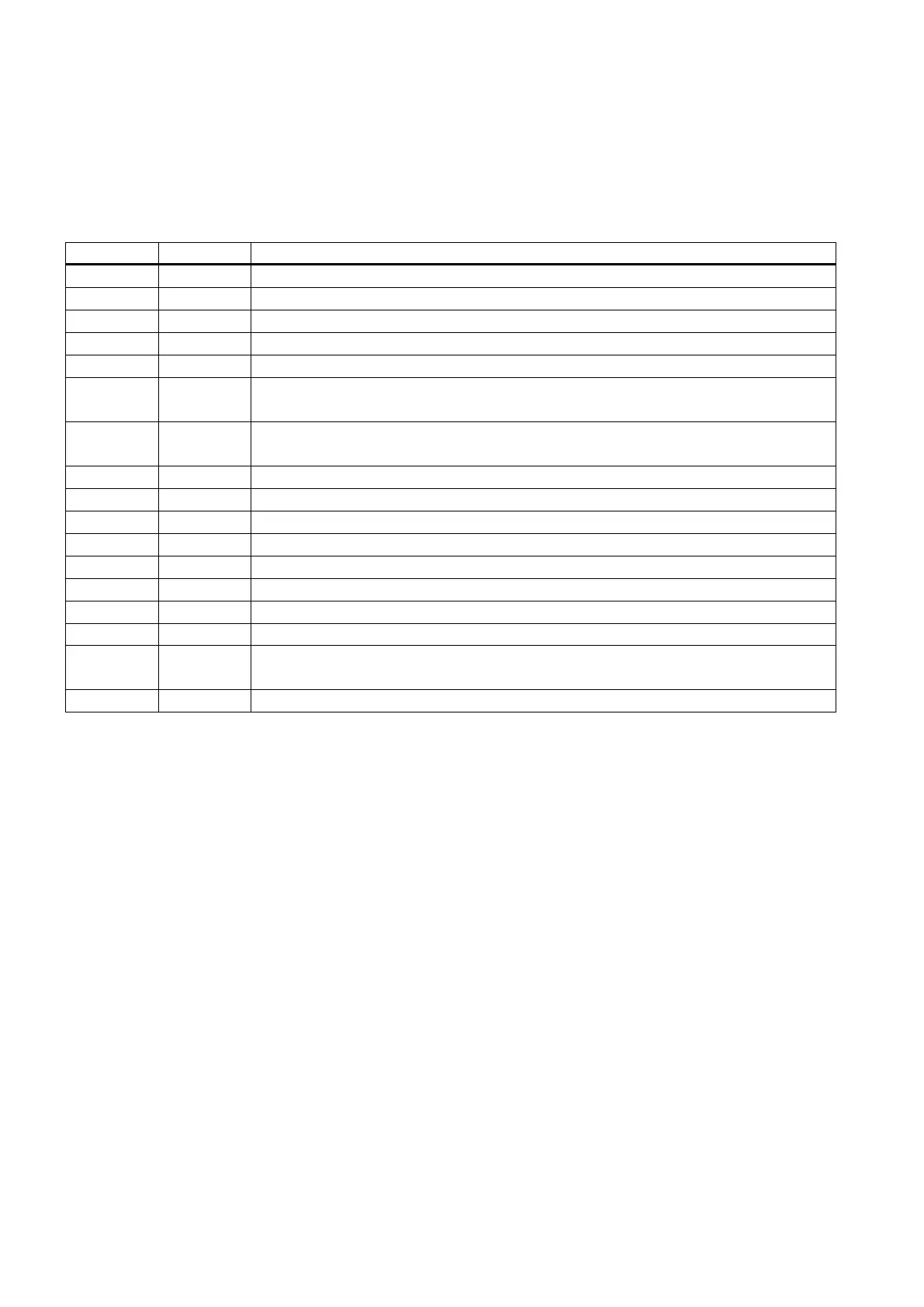

Groove - CYCLE93

Programming

CYCLE93 (SPD, SPL, WIDG, DIAG, STA1, ANG1, ANG2, RCO1, RCO2, RCI1, RCI2, FAL1, FAL2, IDEP, DTB, VARI,

_VRT)

Starting point along facing axis

Starting point along longitudinal axis

Groove width (enter without sign)

Groove depth (enter without sign)

Longitudinal: 0<=STA<=180, face: STA=90

ANG1 REAL Flank angle 1: on the side of the groove determined by the starting point (enter without sign)

Range of values: 0<=ANG1<89.999 degrees

ANG2 REAL Flank angle 2: on the other side (enter without sign)

Range of values: 0<=ANG2<89.999

Radius/chamfer 1, externally: on the side determined by the starting point

Radius/chamfer 2, externally

Radius/chamfer 1, internally: on the starting point side

Radius/chamfer 2, internally

Finishing allowance at the recess base

Finishing allowance at the flanks

Infeed depth (enter without sign)

Dwell time at recess base

VARI INT Machining type

Range of values: 1...8 and 11...18

Variable retraction path for grooving, incremental (enter without sign)

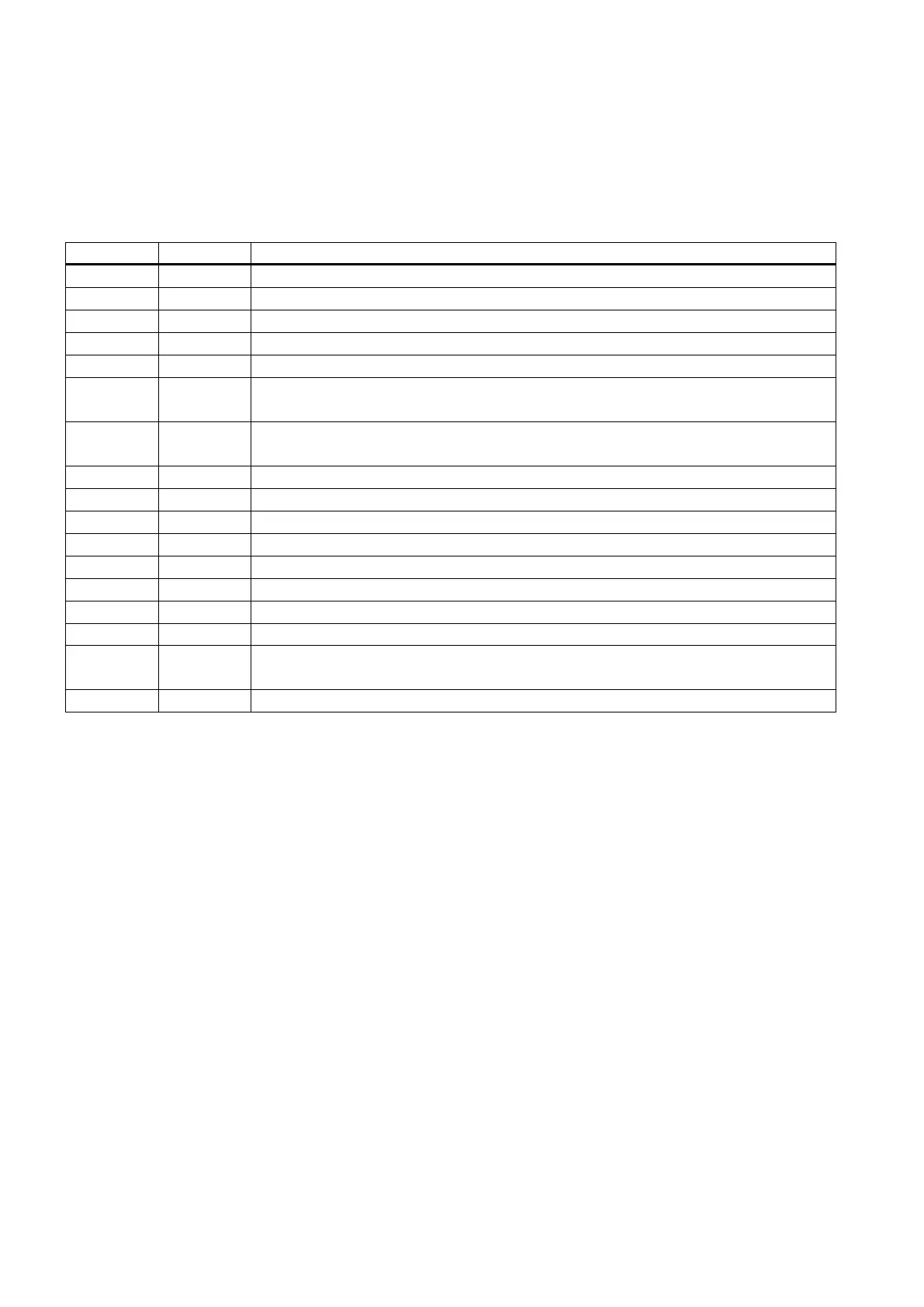

The grooving cycle can be used to carry out symmetrical and asymmetrical grooves for longitudinal and face machining at

any straight contour elements. External and internal grooves can be produced.

The infeed in the depth (towards the groove base) and in the width (from groove to groove) are calculated in the cycle

internally and distributed equally with the maximum possible value.

When grooving at oblique faces, the tool will traverse from one groove to the next on the shortest path, that is, parallel to the

cone at which the groove is machined. During this process, a safety clearance to the contour is calculated by the cycle

internally.

Paraxial roughing down to the base of the groove in single infeed steps.

After each infeed, the tool is retracted for chip breaking.

Loading...

Loading...