Programming and Operating Manual (Turning)

01/2017

175

1. The tool first moves to the starting point calculated internally in the cycle at rapid traverse.

2. The chamfer or radius is machined at the machining feedrate.

3. Cut-off down to depth DIAG1 is performed at the machining feedrate.

4. Cut-off is continued down to depth DIAG2 at reduced feedrate FF2 and reduced spindle speed SS2.

5. The tool moves back to the safety distance at rapid traverse.

N10 G0 G90 Z30 X100 T5 D1 S1000 M3

;Starting point before the beginning of

the cycle

; Specification of technology values

N30 CYCLE92(60, -30, 40, -2, 2, 1, 800, 200,3,1,1,300, 0,

0, 1, 0, 11000)

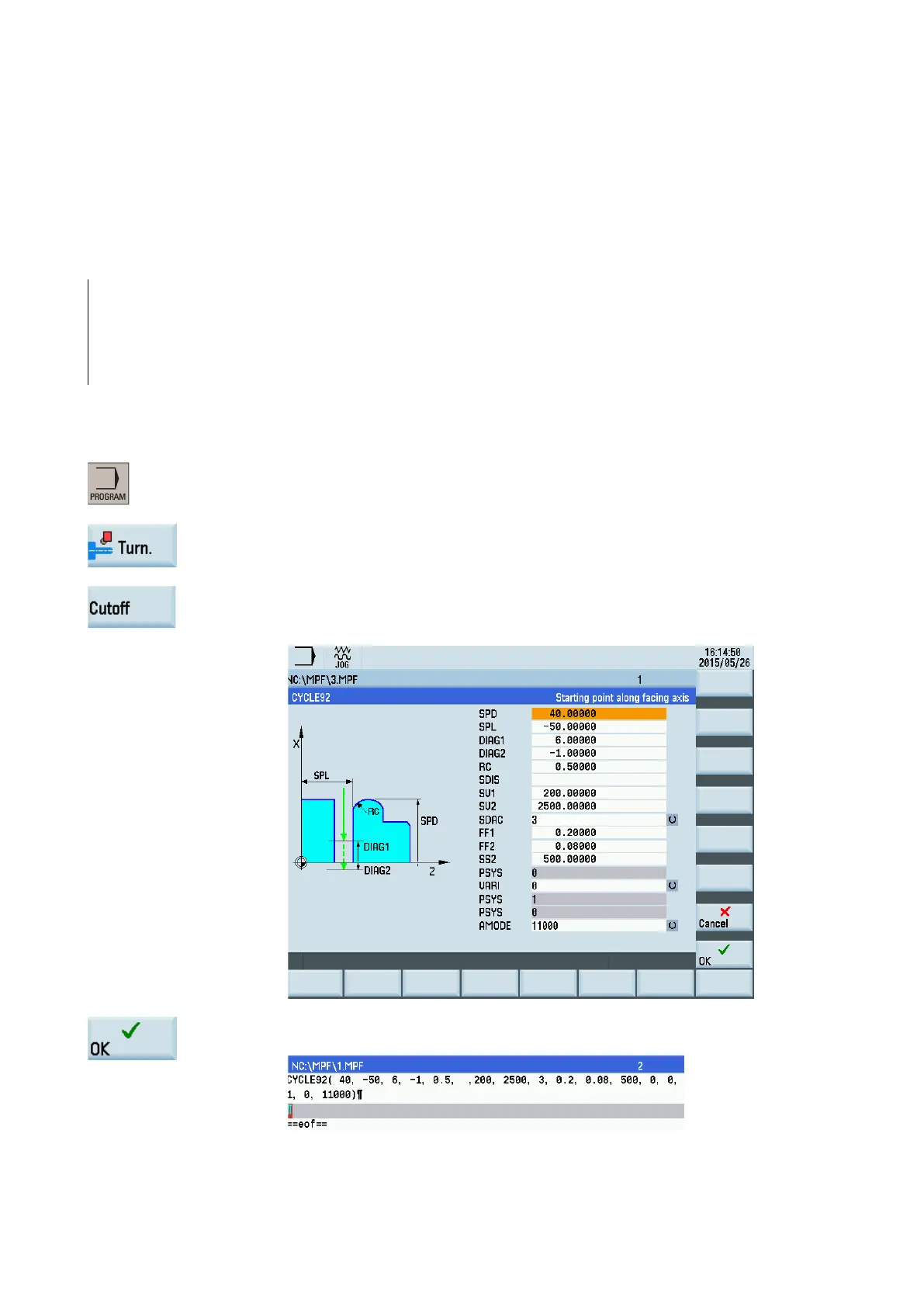

The cycle can be found and parameterized from the main screen of the turning cycles.

Select the program editing operating area.

Open the vertical softkey bar for available turning cycles.

Press this softkey to open the window for CYCLE92. Parameterize the cycle as desired.

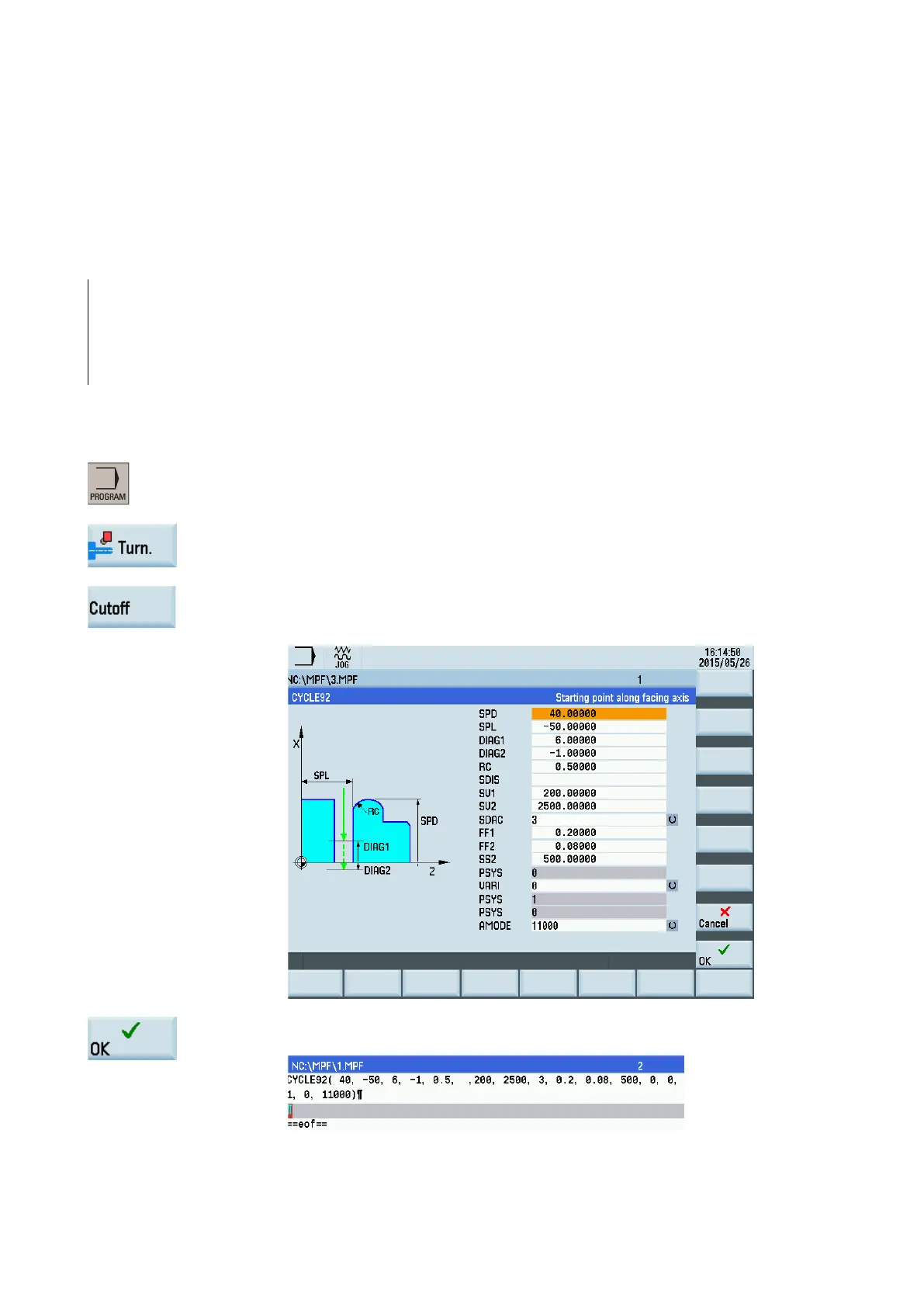

Confirm your settings with this softkey. The cycle is then automatically transferred to the

progr

am editor as a separate block.

Loading...

Loading...