Programming and Operating Manual (Turning)

152 01/2017

● The spindle of the driven tool must be declared to the master spindle (SETMS command).

● The drilling position can be programmed either with Z and the C-axis or, if TRACYL is active, with X and Z.

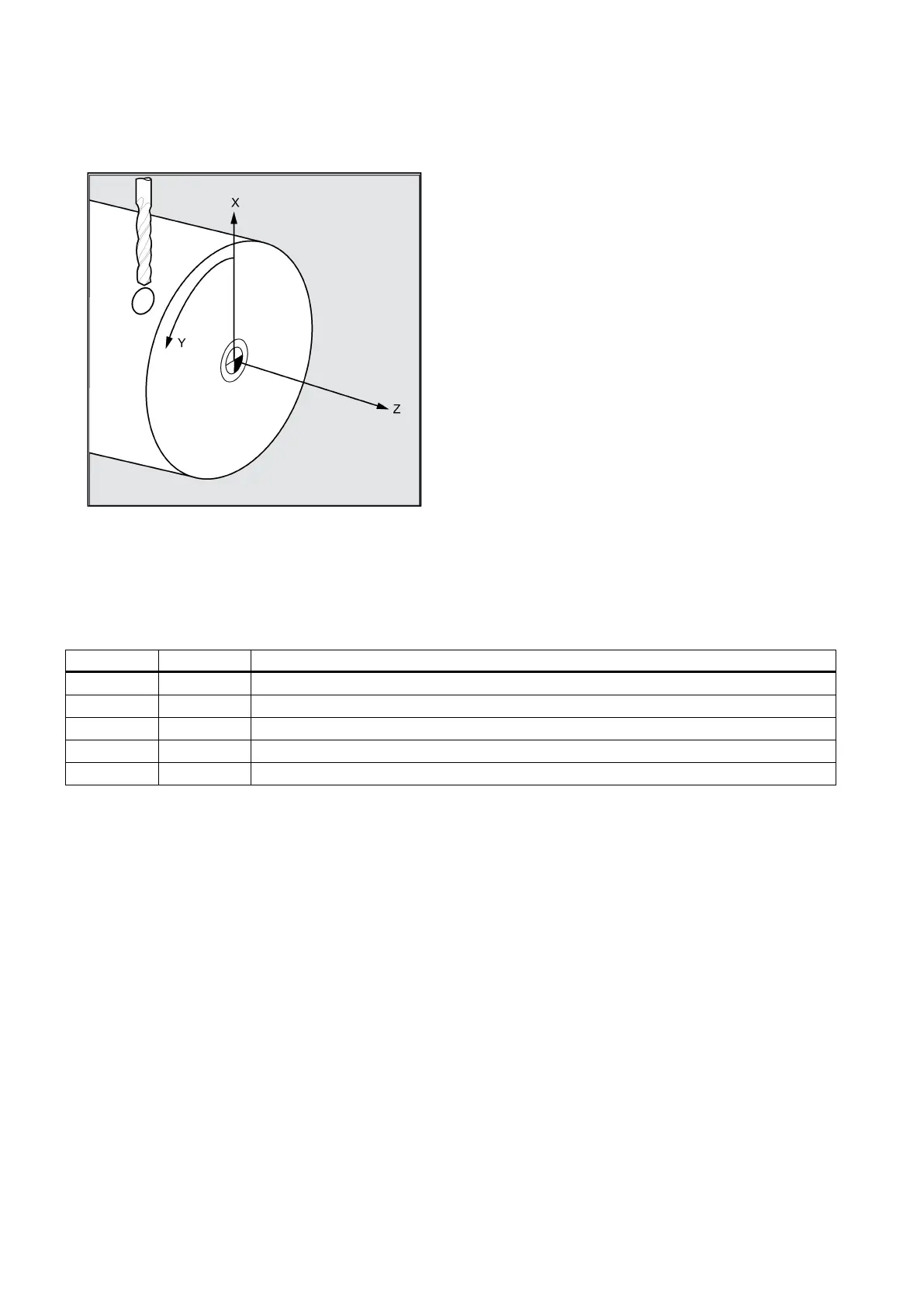

See the following illustration for drilling on peripheral surface with a driven tool:

Drilling, centering - CYCLE81

Programming

CYCLE81 (RTP, RFP, SDIS, DP, DPR)

Retraction plane (absolute)

Reference plane (absolute)

Safety clearance (enter without sign)

Final drilling depth (absolute)

Final drilling depth relative to the reference plane (enter without sign)

The tool drills at the programmed spindle speed and feedrate to the entered final drilling depth.

Sequence

Position reached prior to cycle start:

The drilling position is the position in the two axes of the selected plane.

The cycle creates the following sequence of motions:

● Approaching the position of safety distance relative to the reference plane with G0

● Traversing to the final drilling depth with the feedrate (G1) programmed prior to the cycle call

● Retracting to the retraction plane with G0

Loading...

Loading...