Programming and Operating Manual (Turning)

216 01/2017

Machining typical turning parts

13.1

Operations before programming

Operating sequence

Turn on the power supply for the machine tool. Proceed with the operations for the refe

r-

ence point approach, if the machine axis is equipped with an incremental encoder (see

Chapter "Switching on and referencing (Page 18)").

Create the required tools (see Section "Creating a tool (Page 20)").

Activate the tools and the spindle (see Section "

Activating the tool and the spindle

Proceed with the handwheel assignment operations if the machine manufacturer has not

assigned the handwheel for the control system (see Chapter "

Assigning the handwheel

Proceed with the tool setting operations to finish measuring all the tools (see Section

"Additional method for measuring the tool (Page 258)").

Verify the tool offset result to guarantee the safety and correctness of machining (see Se

c-

tion "Verifying the tool offset result (Page 31)").

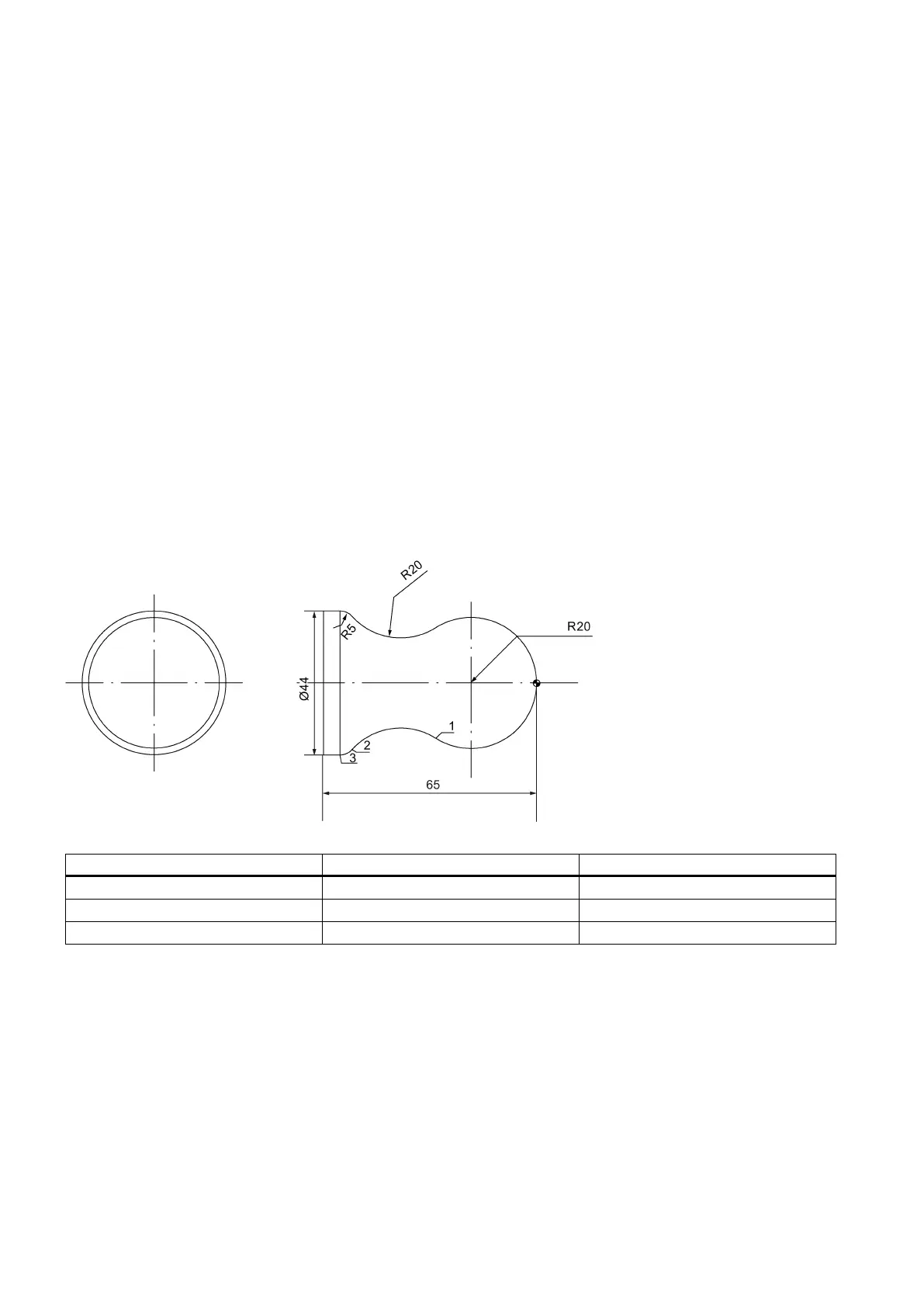

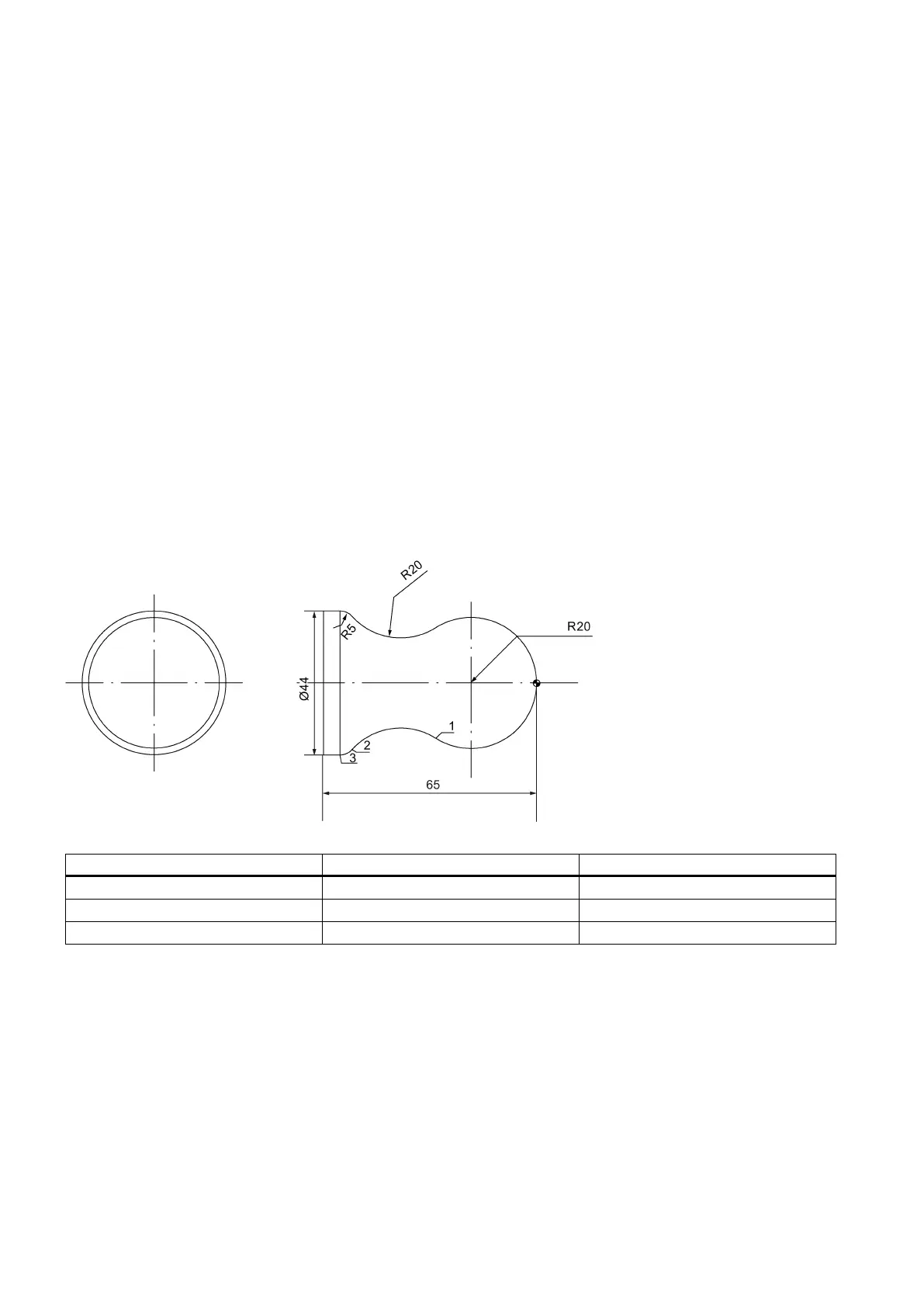

Programming for machining a spherical surface (Example 1)

Workpiece drawing (unit: mm)

Coordinates of key machining points

1 33.762 -30.726

● The arc transition must be smooth, without lapping.

● The cutting trace must be even.

● The sharp edges must be rounded.

Blank material: aluminum bar

Blank diameter: 45 mm

Blank length: 100 mm (machining limit along the Z axis: Z-66; three-jaw chuck clamping length: 25 mm)

Loading...

Loading...