Programming and Operating Manual (Turning)

174 01/2017

Cutoff - CYCLE92

Programming

CYCLE92 (SPD, SPL, DIAG1, DIAG2, RC, SDIS, SV1, SV2, SDAC, FF1, FF2, SS2, 0, VARI, 1, 0, AMODE)

Starting point along facing axis (absolute, always diameter)

Starting point in the longitudinal axis (absolute)

Depth for speed reduction ∅ (absolute)

Chamfer width or rounding radius

Safety clearance (to be added to the reference point; enter without sign)

Maximum speed at constant cutting speed

Direction of spindle rotation (values: 3 = M3; 4 = M4)

Feed to depth for speed reduction

Reduced feed up to final depth, mm/rev

Reduced speed up to final depth

Internal parameter; only the default value 0 is possible

Machining type (values: 0 = Retraction to SPD + SDIS; 1 = No retraction)

Internal parameter; only the default value 1 is possible

Internal parameter; only the default value 0 is possible

Alternate mode: radius or chamfer (values: 10000 = radius; 11000 = chamfer)

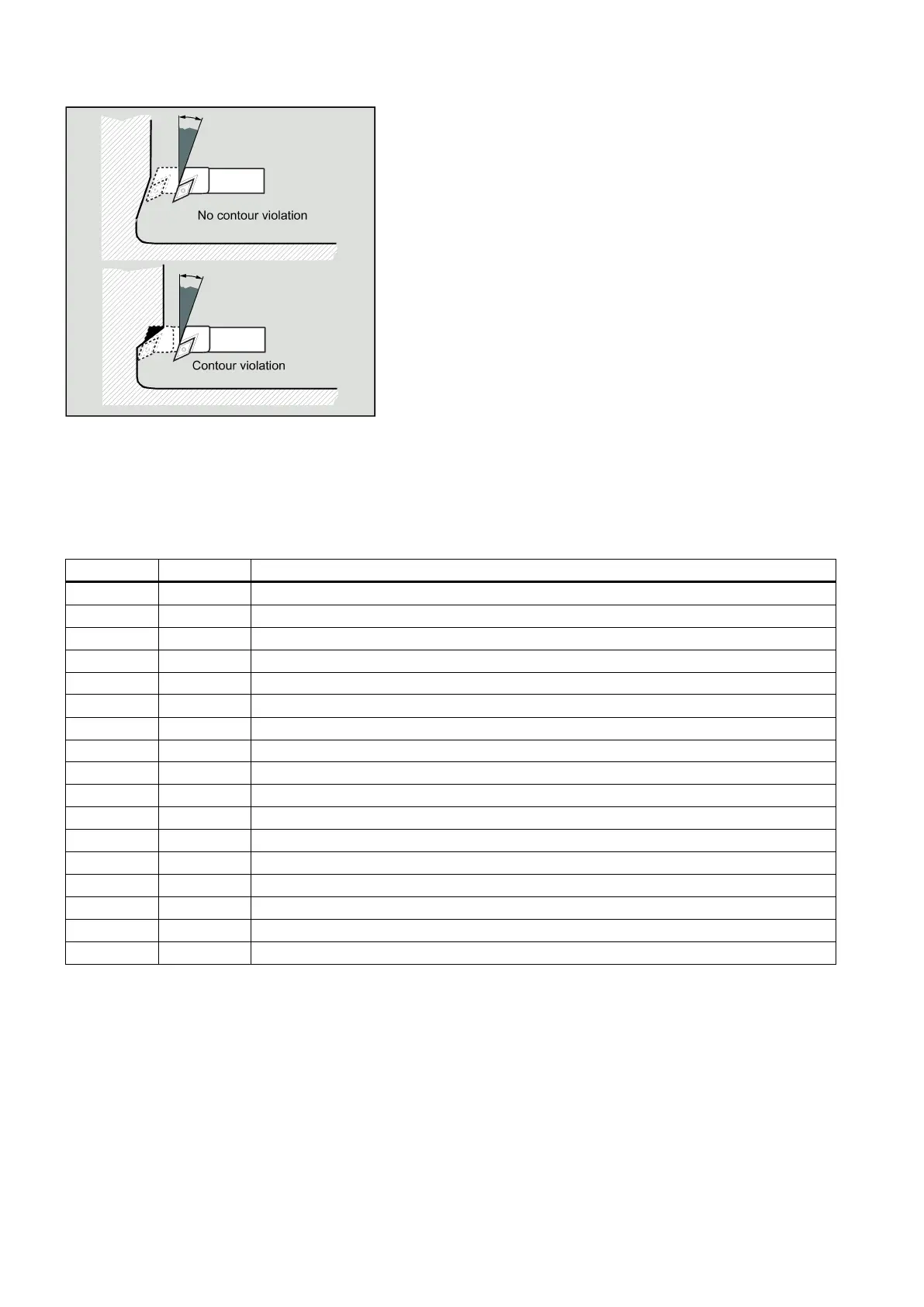

CYCLE92 is used to cut off balanced parts (for example, screws, bolts, or pipes) dynamically.

You can program a chamfer or rounding on the edge of the machined part. You can machine at a constant cutting rate V or

speed S up to a depth DIAG1, from which point the workpiece is machined at a constant speed. As of depth DIAG2, you can

also program a reduced feedrate FF2 or a reduced speed SS2, in order to adapt the velocity to the smaller diameter.

Use parameter DIAG2 to enter the final depth that you wish to reach with the cut-off. With pipes, for example, you do not

need to cut-off until you reach the center; cutting off slightly more than the wall thickness of the pipe is sufficient.

Loading...

Loading...