Programming and Operating Manual (Turning)

106 01/2017

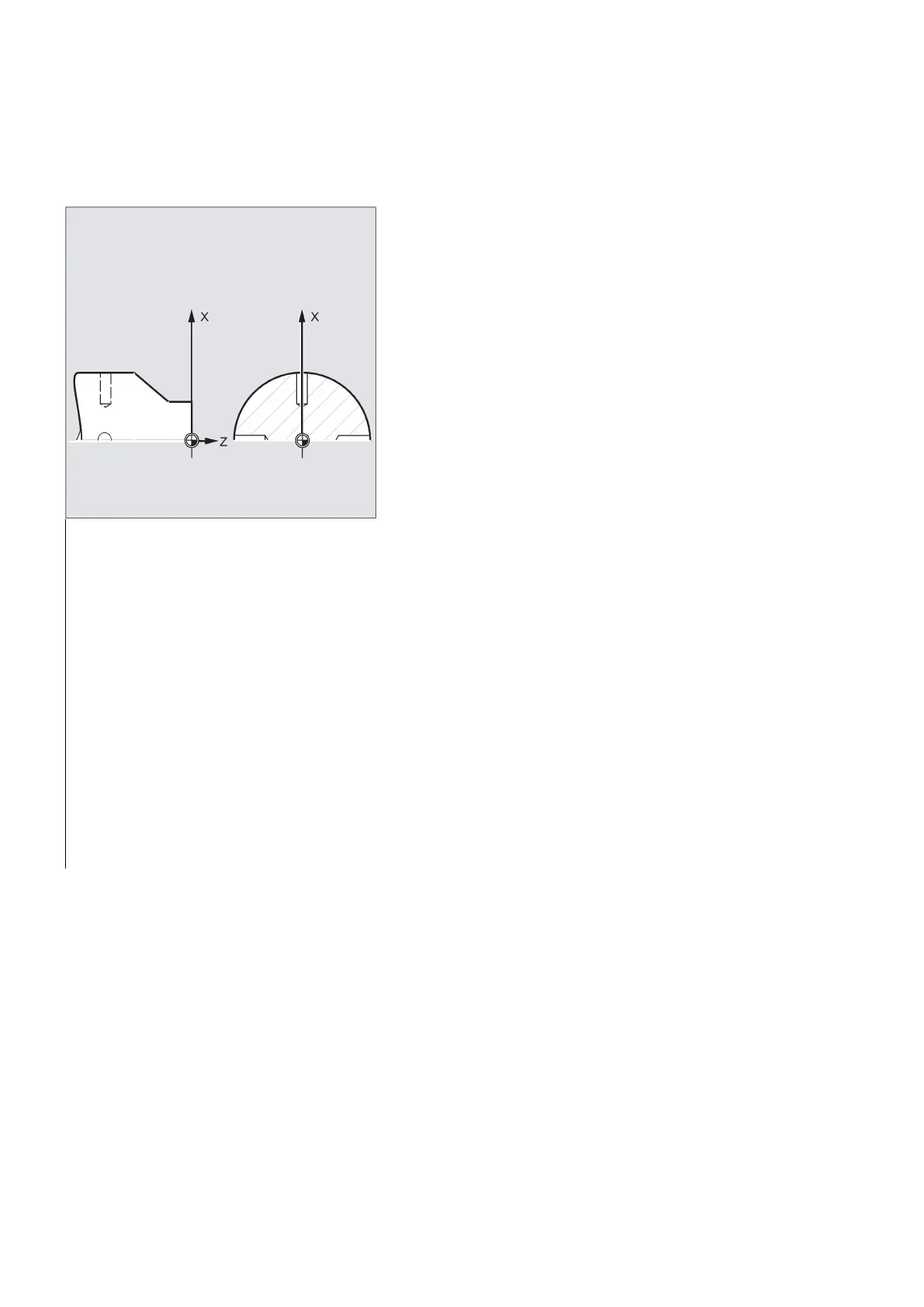

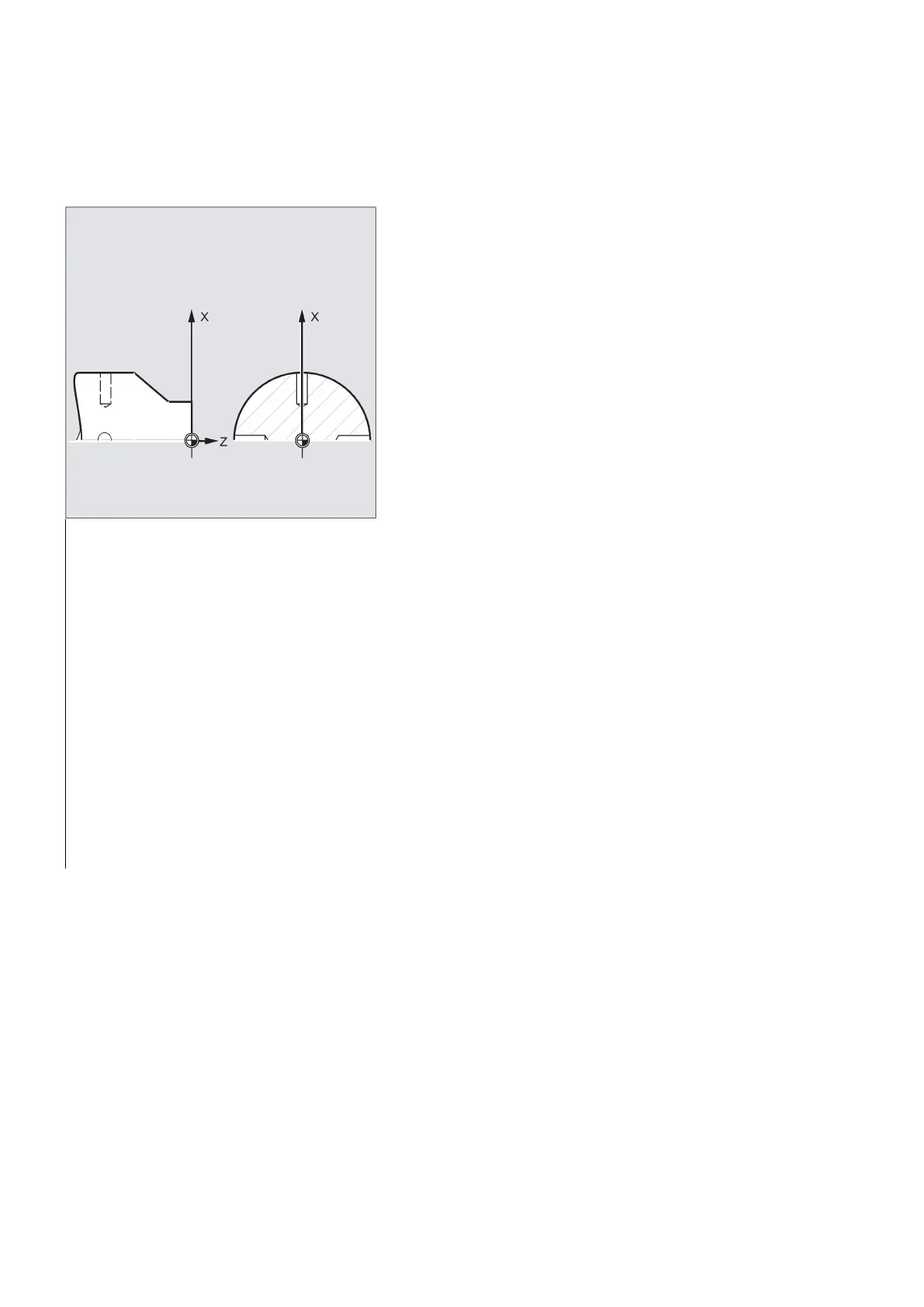

Example 3: Drill cross holes in turned part

Cross holes are to be drilled in this turned part. The running spindle is stopped at zero degrees and then successively turned

through 90°, stopped and so on.

Switch on cross drilling attachment.

Set main spindle to 0° immediately,

the program will advance to the next block straight away.

Switch on the drill while the spindle is taking up position.

Wait for the main spindle to reach its position.

Feedrate in mm/min (G96 is suitable only for the multi-edge turn-

ing tool and synchronous spindle, but not for power tools on the

The spindle is positioned through 90° with read halt in a positive

direction.

The spindle is positioned at 180° relative to the spindle zero

point.

The spindle turns in a positive direction through 90° from the

absolute 180° position, ending up in the absolute 270° position.

Loading...

Loading...