Programming and Operating Manual (Turning)

01/2017

109

If G94 instead of G95 was active before, a new appropriate F value must be written.

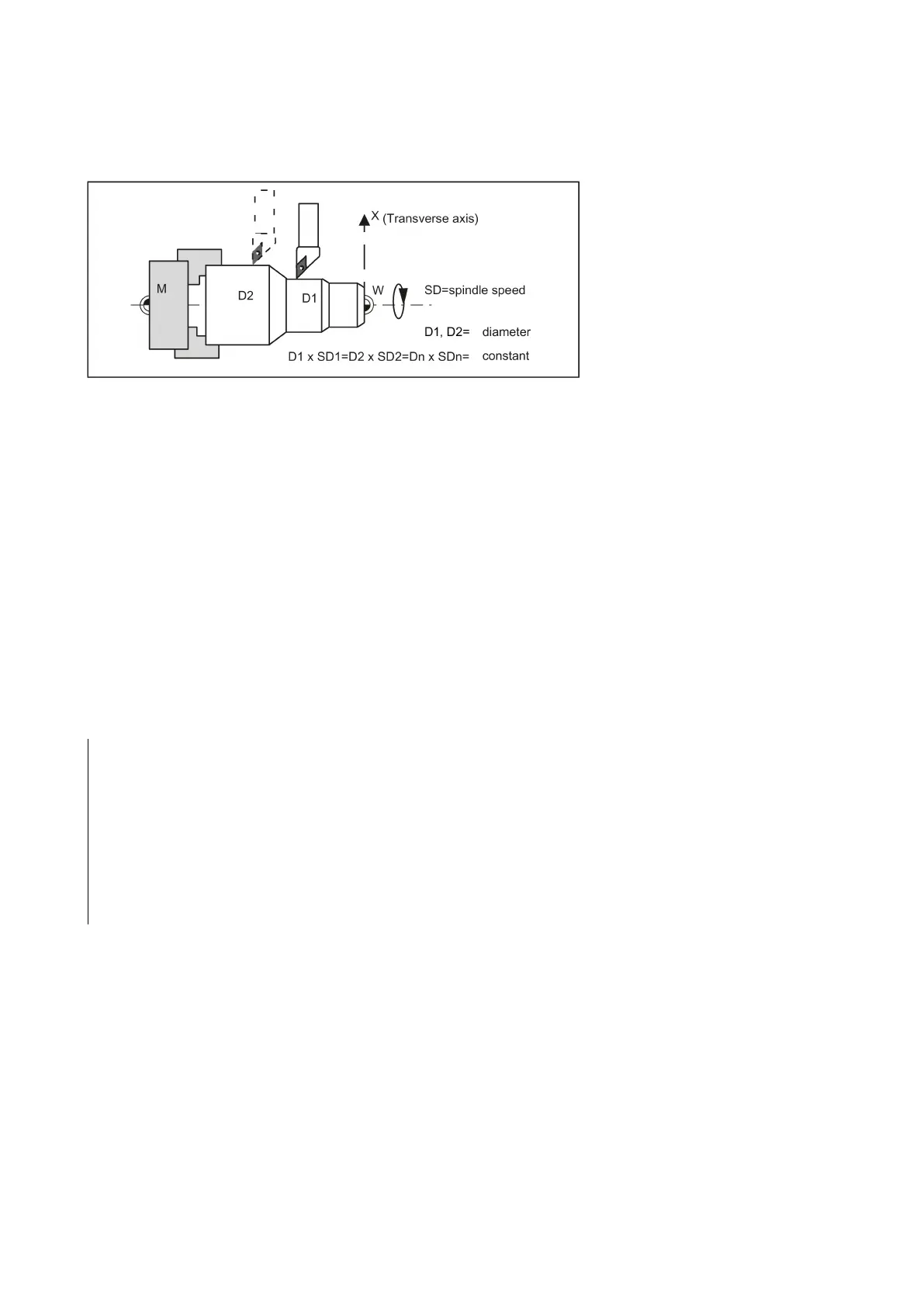

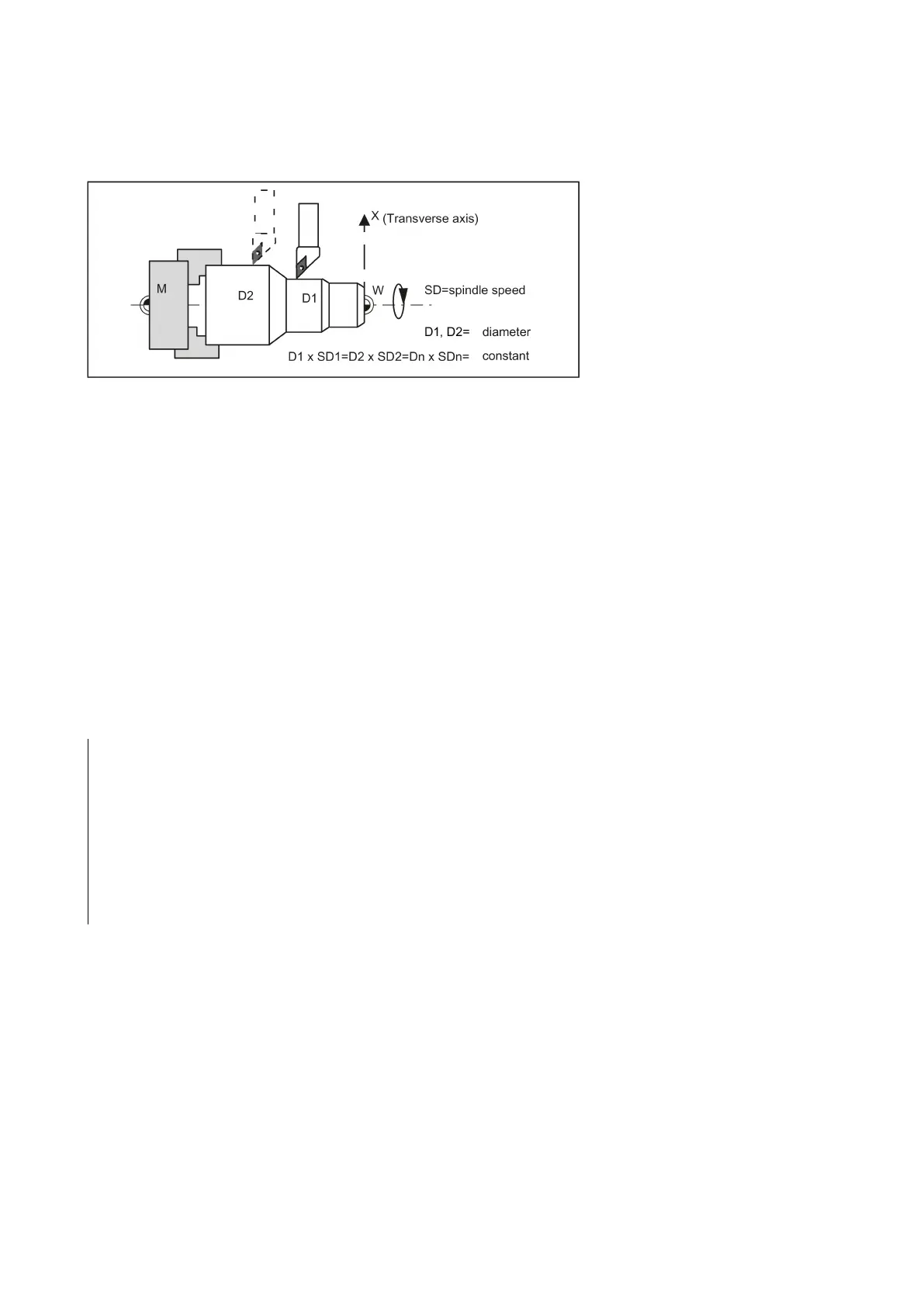

See the following illustration for constant cutting rate G96:

With rapid traverse G0, there is no change in speed.

If the contour is approached at rapid traverse and the next block contains an interpolation type G1 or G2, G3,

CIP, CT (contour block), then the speed for the contour block is applied already in the approach block with G0.

When machining from large to small diameters, the spindle speed can increase significantly. In this case, it is recommended

to program the upper spindle speed limitation LIMS=... . LIMS is only effective with G96 and G97.

By programming LIMS=..., the value entered into the setting data (SD43230: SPIND_MAX_VELO_LIMS) is overwritten. This

SD takes effect when LIMS is not written.

The upper limit speed programmed with G26 or defined via machine data cannot be overwritten with LIMS=.

Deactivate constant cutting rate: G97

The function "Constant cutting rate" is deactivated by G97. If G97 is active, a programmed

is given in RPM as the

.

If no new S word is programmed, the spindle turns at the last defined speed with G96 function active.

; Spindle's direction of rotation

; Activate constant cutting speed, 120 m/min, speed limit 2,500

r.p.m.

; no change in speed, because block N31 with G0

; no change in speed, because block N32 with G0

; Approach on contour, new speed is automatically set as is required

for the beginning of block N40

; Feedrate 0.2 mm/revolution

; Deactivating constant cutting rate

; new spindle speed, r.p.m.

The G96 function can also be deactivated with G94 or G95 (same G group). In this case, the last

spindle speed

S is active for the remaining machining sequence if no new S word is programmed.

The programmable offset TRANS or ATRANS (see Section "Programmable work offset: TRANS, ATRANS (Page 81)")

should not be used on the transverse axis X or used only with low values. The workpiece zero point should be located at the

turning center. Only then is the exact function of G96 guaranteed.

Loading...

Loading...