Programming and Operating Manual (Turning)

202 01/2017

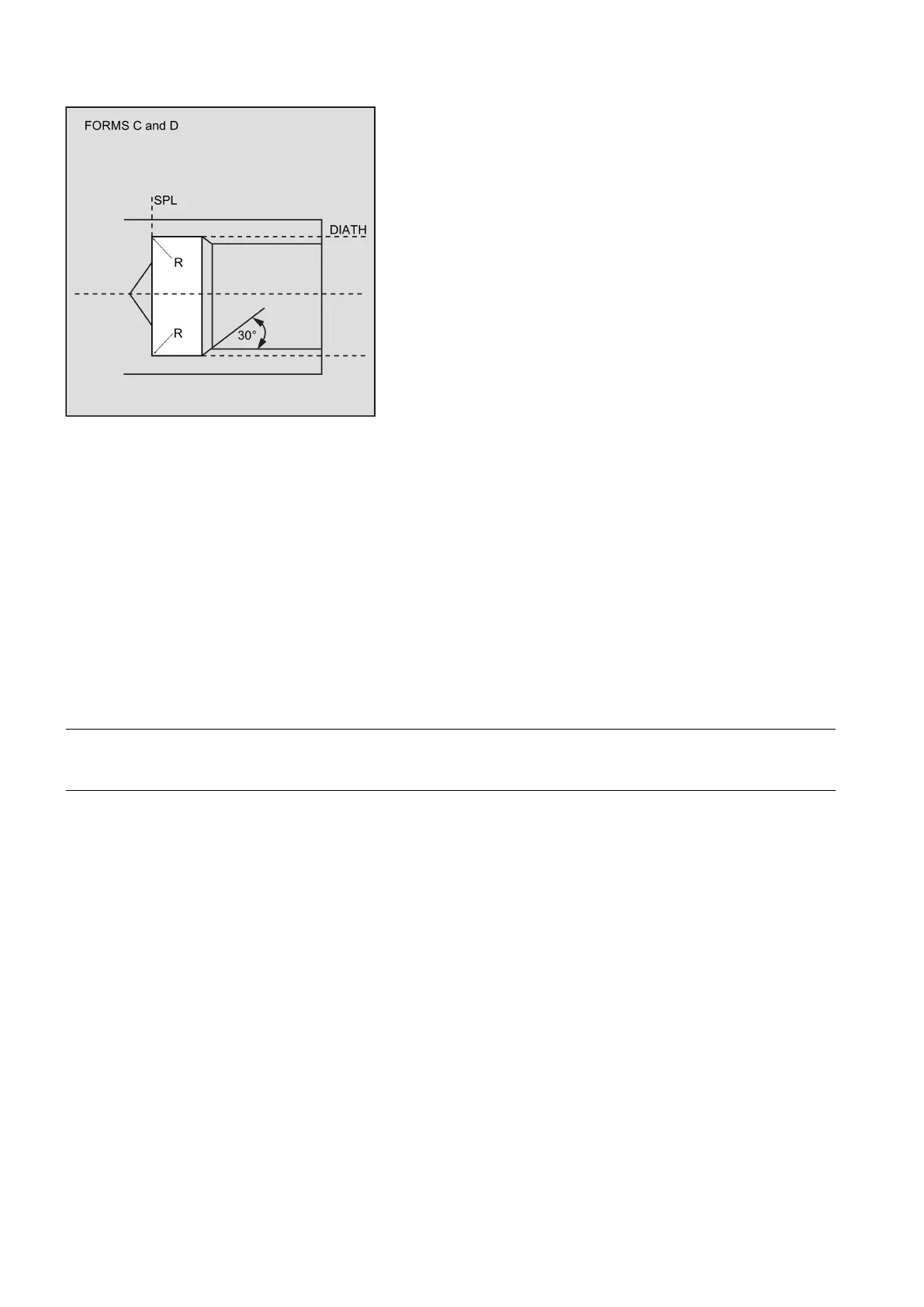

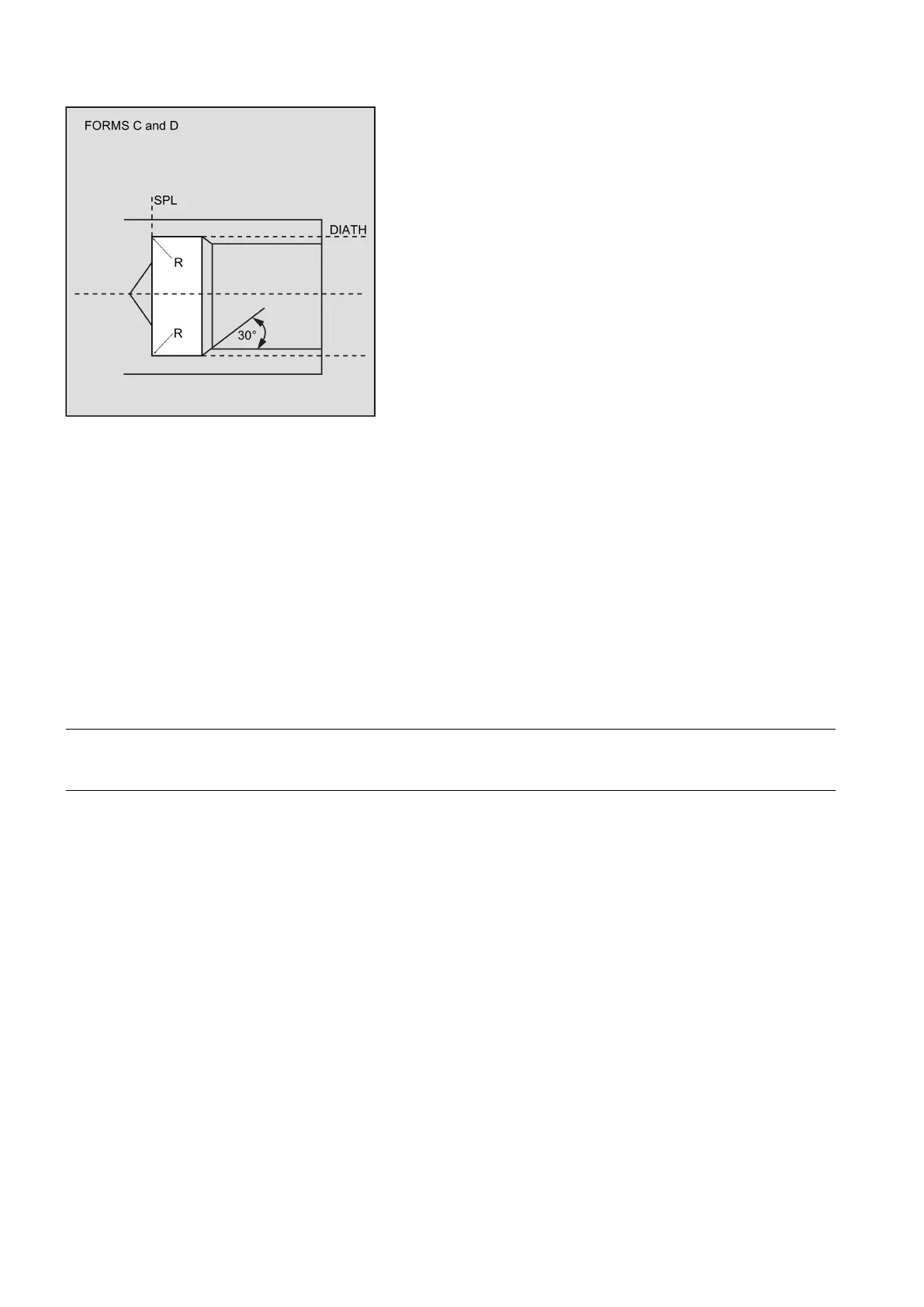

If the parameter has a value other than A ... D, the cycle aborts and creates alarm 61609 "Form defined incorrectly".

Internally in the cycle, the tool radius compensation is selected automatically.

The cycle only uses the tool point directions 1 ... 4. If the cycle detects a tool point direction 5 ... 9 or if the form of the

undercut cannot be machined with the selected tool point direction, alarm 61608 "Wrong tool point direction programmed" is

issued, and the cycle is canceled.

The position of the undercut can be either specified directly or derived from the tool point direction with the VARI parameter.

See also Section "Undercut (forms E and F to DIN) - CYCLE94 (Page 183)".

The cycle will find the starting point determined by the tool point direction of the active tool and the thread diameter

automatically. The position of this starting point referred to the programmed coordinate values is determined by the tool point

direction of the active tool.

For the forms A and B, the undercut angle of the active tool is monitored in the cycle. If it is detected that the form of the

undercut cannot be machined using the selected tool, the message "Changed form of undercut" will be displayed on the

control system; the machining, however, is continued.

Note

Before calling the cycle, a tool compensation must be activated; otherwise, the cycle is terminated and the error message

61000 "No tool compensation active" is issued.

Programming example: Thread undercut form A

This program can be used to program a thread undercut of form A.

Loading...

Loading...