Programming and Operating Manual (Turning)

01/2017

209

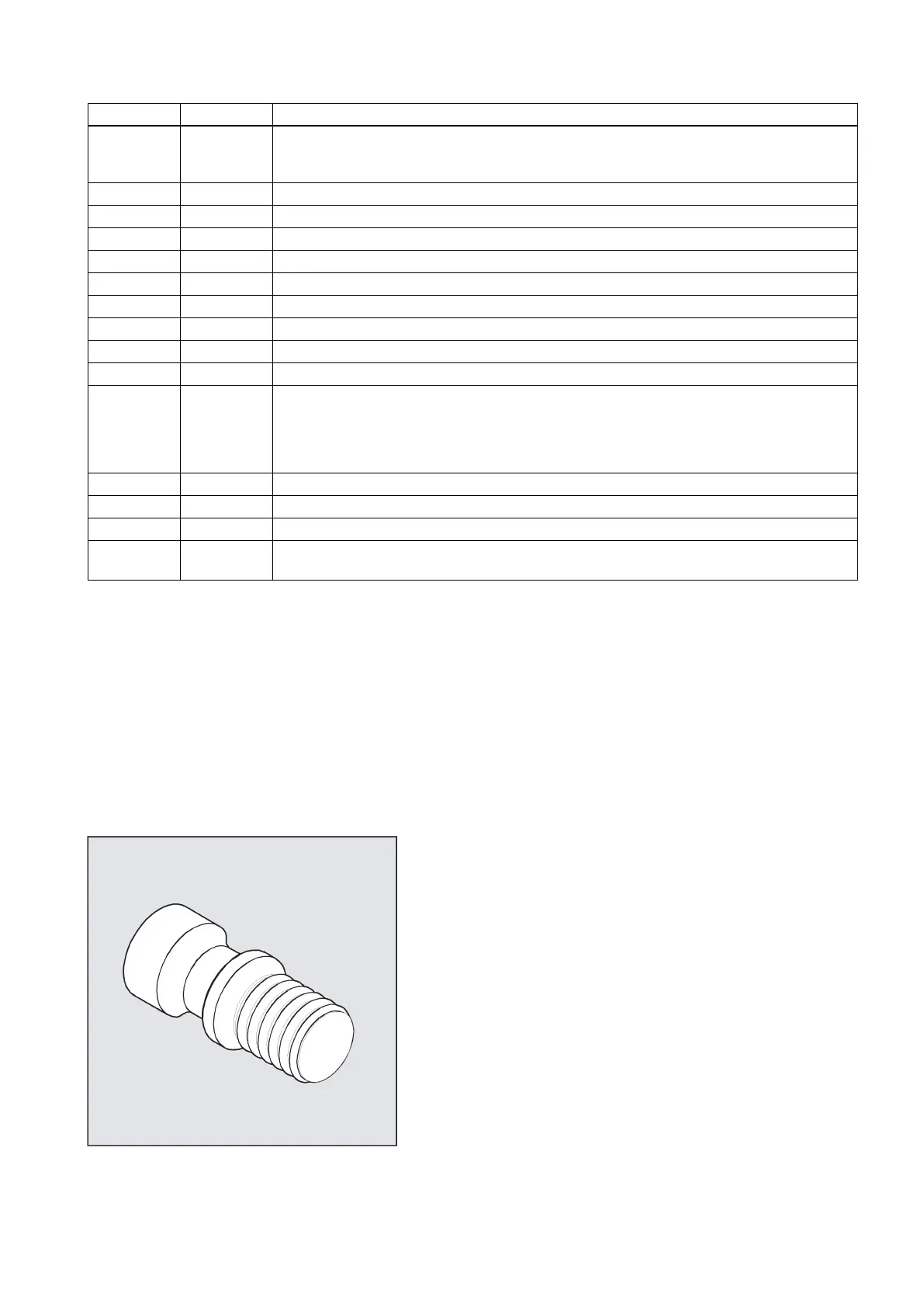

VARI INT Definition of the machining type for the thread (values: 300101 = external thread with linear

infeed; 300102 = internal thread with linear infeed; 300103 = external thread with degressive

infeed; 300104 = internal thread with degressive infeed)

Number of threads (enter without sign)

Variable retraction path for thread cutting, incremental (enter without sign)

Internal parameter, only the default value 0 is possible (value: 0)

Internal parameter, only the default value 0 is possible (value: 0)

Internal parameter, only the default value 0 is possible (value: 0)

Internal parameter, only the default value 0 is possible (value: 0)

Internal parameter, only the default value 0 is possible (value: 0)

Internal parameter, only the default value 0 is possible (value: 0)

PSYS INT Internal parameter, only the default value 0 is possible (value: 0)

PITA INT Unit of parameter PIT (thread pitch)

Values:

1 = pitch in mm/revolution

2 = pitch in threads per inch(TPI)

PSYS INT Internal parameter, only the following values are possible (values: 0 = Longitudinal thread;

10 = Face thread; 20 = Taper thread)

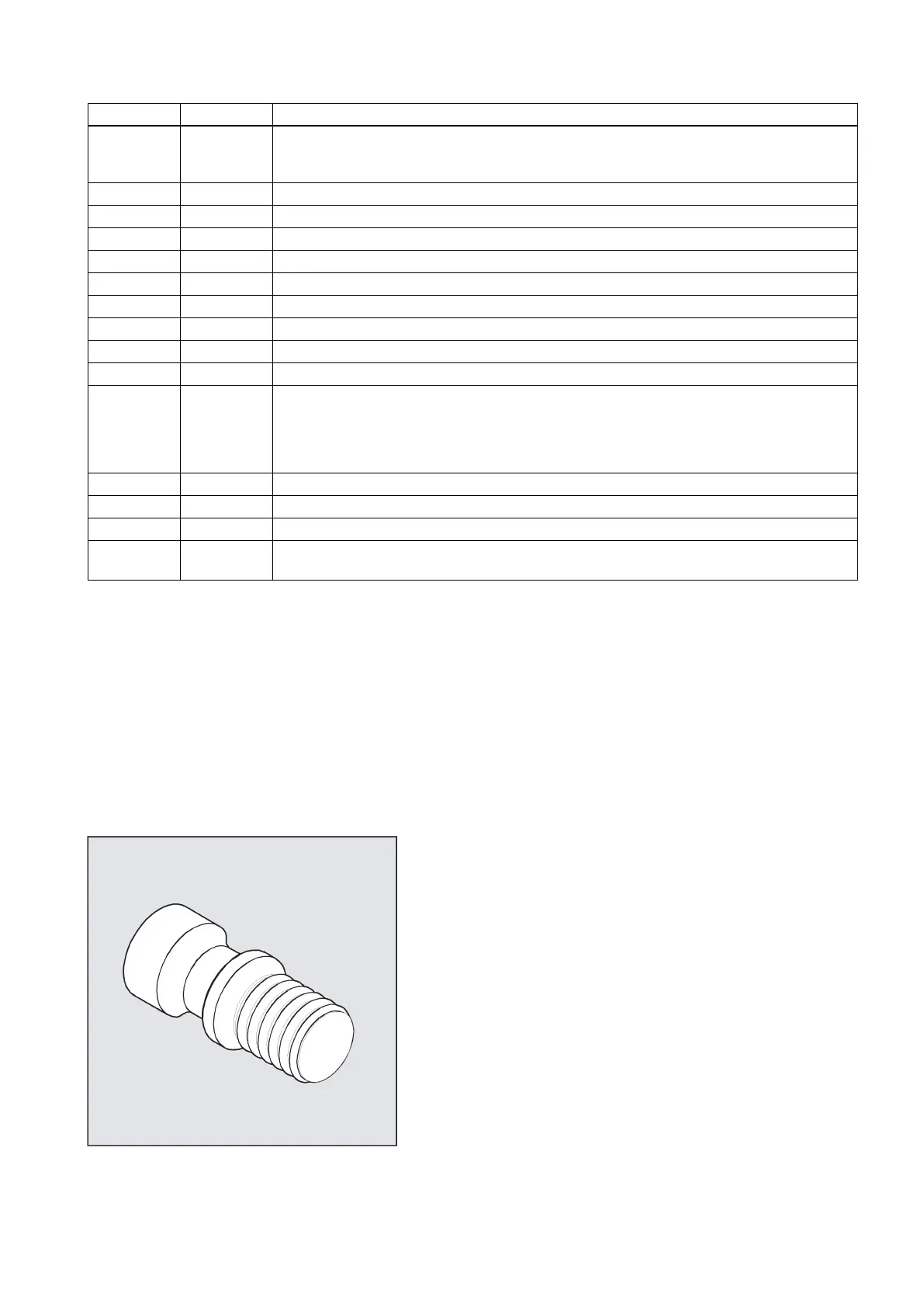

The thread cutting cycle consists of three alternatives: longitudinal thread, face thread or taper thread.

Use this cycle to produce cylindrical and tapered external and internal threads with constant lead in longitudinal and face

machining. The thread can be single or multiple. With multiple threads, the individual thread turns are machined one after

the other.

For thread infeed, you can carry out the infeed with constant infeed depth or constant cutting cross-section.

Right-hand or left hand thread is determined by the direction of rotation of the spindle which must be programmed prior to

the cycle start.

Both feed and spindle override are ineffective in the traversing blocks with thread.

See the following illustration for CYCLE99:

Loading...

Loading...