Programming and Operating Manual (Turning)

01/2017

211

When the thread depth is divided into infeeds with constant cutting cross-section, the cutting force will remain constant over

all roughing cuts. In this case, the infeed will be performed using different values for the infeed depth.

A second version is the distribution of the whole thread depth to constant infeed depths. When doing so, the cutting cross-

section becomes larger from cut to cut, but with smaller values for the thread depth, this technology can result in better

cutting conditions.

The finishing allowance FAL is removed after roughing in one step. Then the idle passes programmed under parameter NID

are executed.

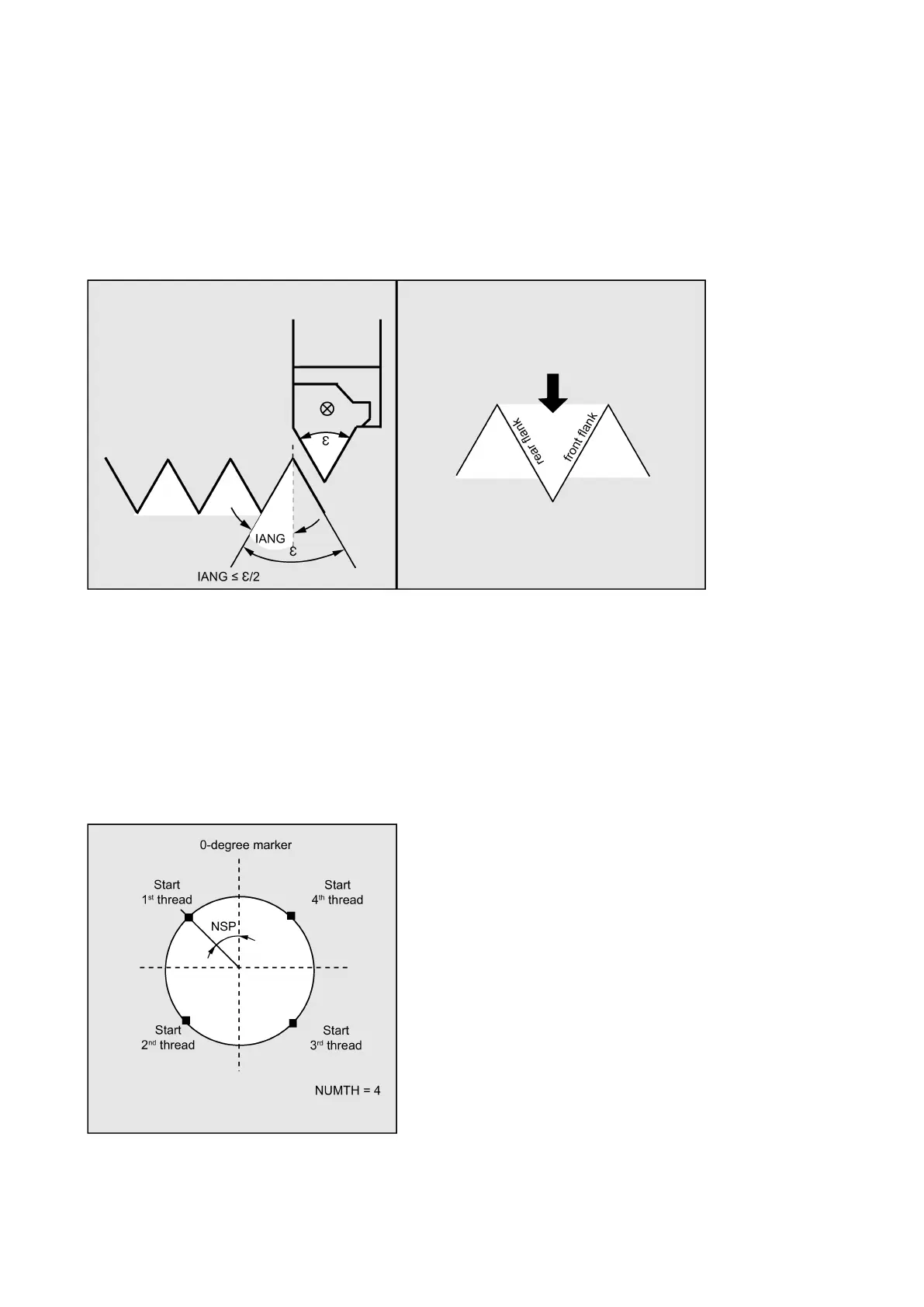

By using parameter IANG, the angle is defined under which the infeed is carried out in the thread. If you wish to infeed at a

right angle to the cutting direction in the thread, the value of this parameter must be set to zero. If you wish to infeed along

the flanks, the absolute value of this parameter may amount maximally to the half of the flank angle of the tool.

The execution of the infeed is defined by the sign of this parameter. With a positive value, infeed is always carried out along

the rear flank, and with a negative value, infeed is always carried out along the front flank. If the value of IANG for tapered

threads is nonetheless negative, the cycle will carry out a flank infeed along a flank.

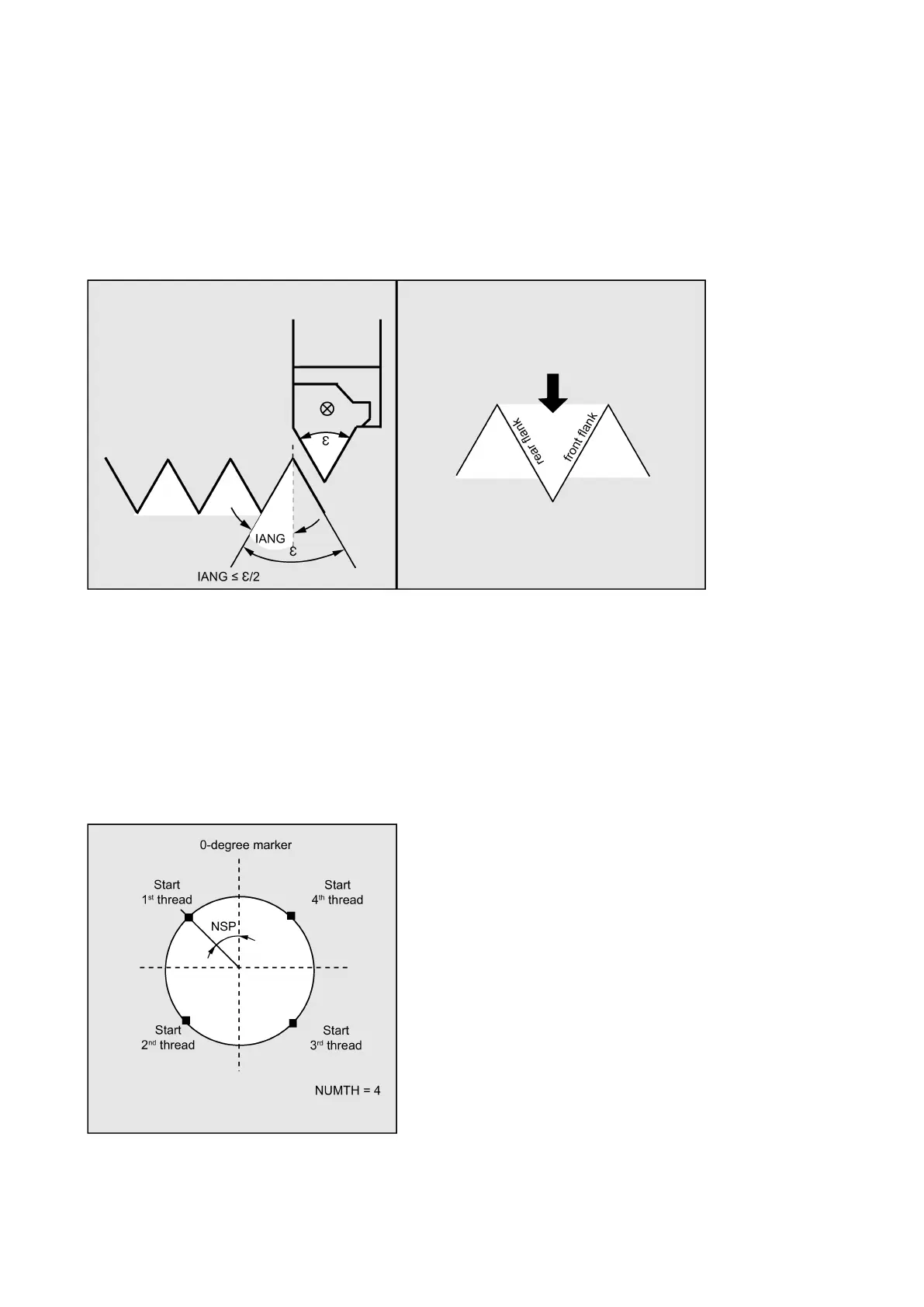

NSP (starting point offset) and NUMTH (number)

You can use this parameter to program the angle value defining the point of the first cut of the thread turn at the

circumference of the turned part. This involves a starting point offset. The parameter can assume values between 0 and

+359.9999 degrees. If no starting point offset has been specified or the parameter has been omitted from the parameter list,

the first thread turn automatically starts at the zero-degree mark.

Loading...

Loading...