Programming and Operating Manual (Turning)

294 01/2017

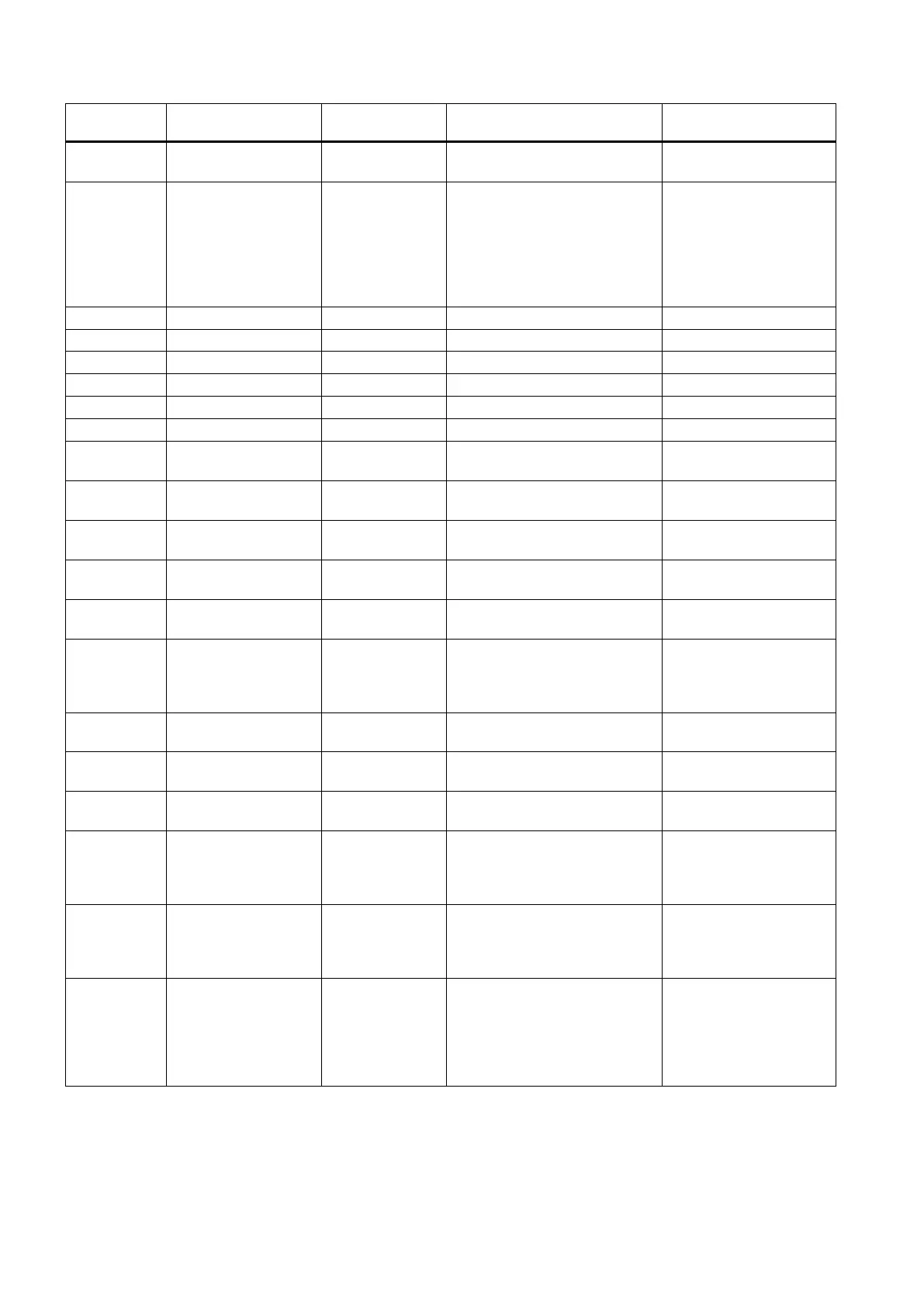

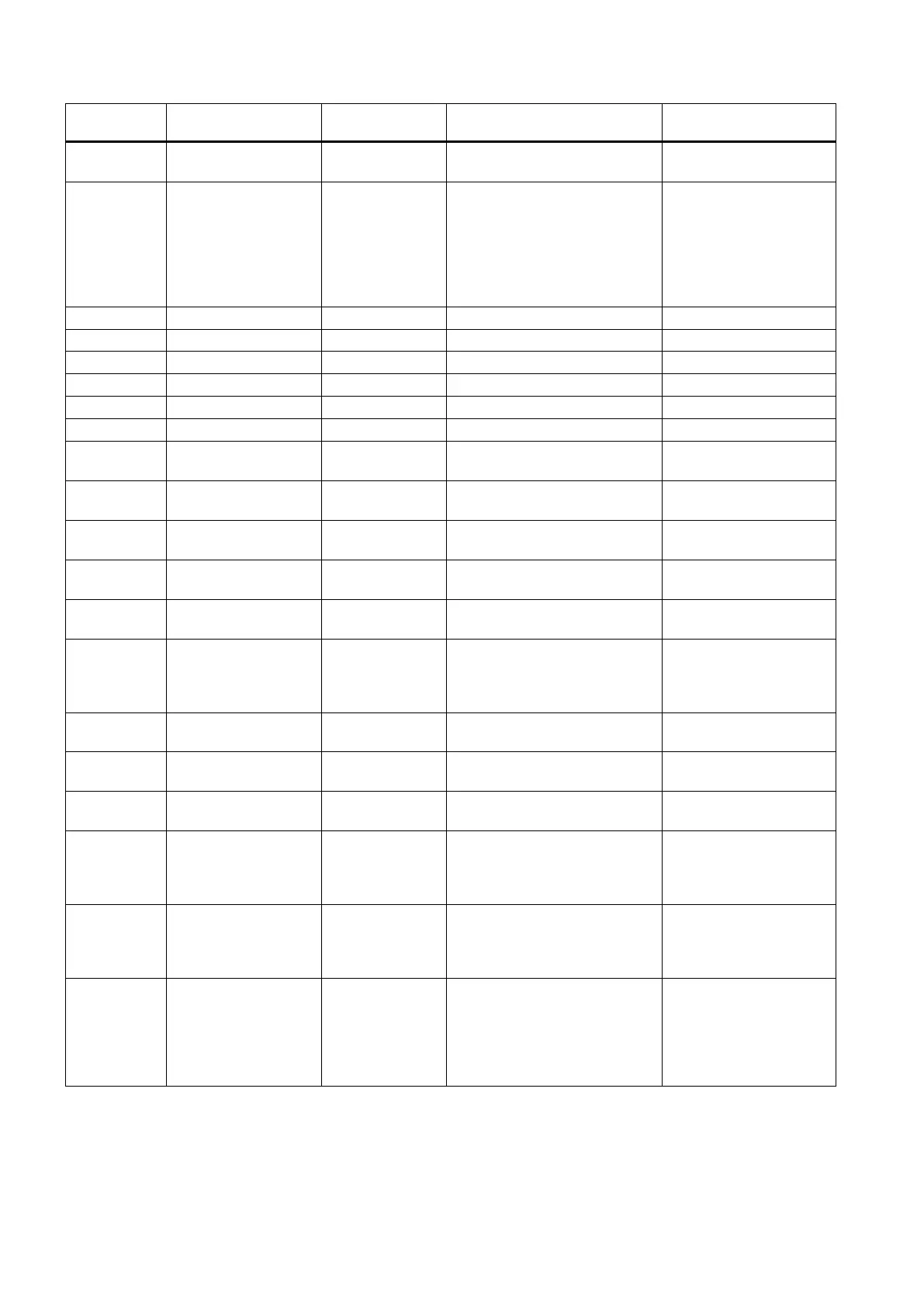

ACOS() Arc cosine R20=ACOS(R2) ; R20: ...

ATAN2( , ) Arctangent2 The angle of the sum vector is

calculated from 2 vectors stand-

ing vertically one on another.

The 2nd vector specified is al-

ways used for angle reference.

Result in the range: -180 to +180

R40=ATAN2(30.5,80.1) ;

R40: 20.8455 degrees

RET Subroutine end Used instead of M2 - to maintain

RET ;separate block

S... Spindle speed

0.001 ... 99

999.999

Unit of measurement of the

spindle r.p.m.

S...

S1=... Spindle speed

0.001 ... 99

Unit of measurement of the

S1=725 ; speed 725

S Cutting rate

0.001 ... 99

Cutting rate unit m/min with G96;

G96

S Dwell time

0.001 ... 99

Dwell time in spindle revolutions G4 S... ;separate block

T Tool number 1 ... 32 000

only integer, no

sign

The tool change can be per-

formed either directly using the T

command or only with M6. This

can be set in the machine data.

T...

X Axis ±0.001 ... 99

Positional data X...

Y Axis ±0.001 ... 99

Positional data Y...

Z Axis ±0.001 ... 99

Positional data Z...

AC Absolute coordinate - The dimension can be specified

for the end or center point of a

certain axis, irrespective of G91.

N10 G91 X10 Z=AC(20)

;X -incremental dimen-

sion,

ACC[

axis

] Percentage accelera-

tion override

1 ... 200, integer Acceleration override for an axis

or spindle; specified as a per-

centage

N10 ACC[X]=80 ;for the X

axis 80%

N20 ACC[S]=50;for the

spindle: 50%

ACP Absolute coordinate;

approach position in

the positive direction

(for rotary axis, spin-

dle)

- It is also possible to specify the

dimensions for the end point of a

rotary axis with ACP(...) irrespec-

tive of G90/G91; also applies to

spindle positioning

N10 A=ACP(45.3)

;approach absolute posi-

tion of the A axis in

the positive direction

N20 SPOS=ACP(33.1)

Loading...

Loading...