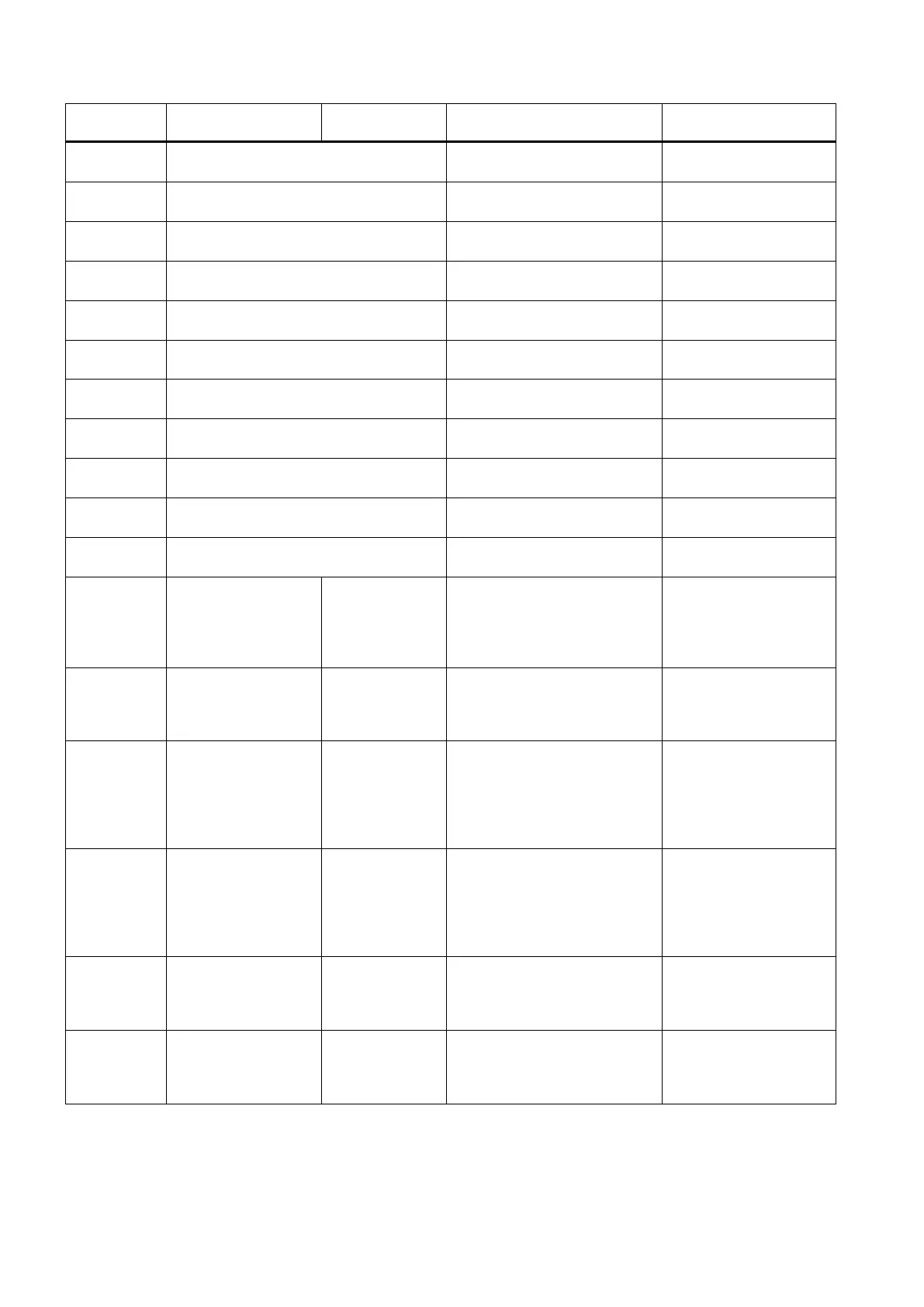

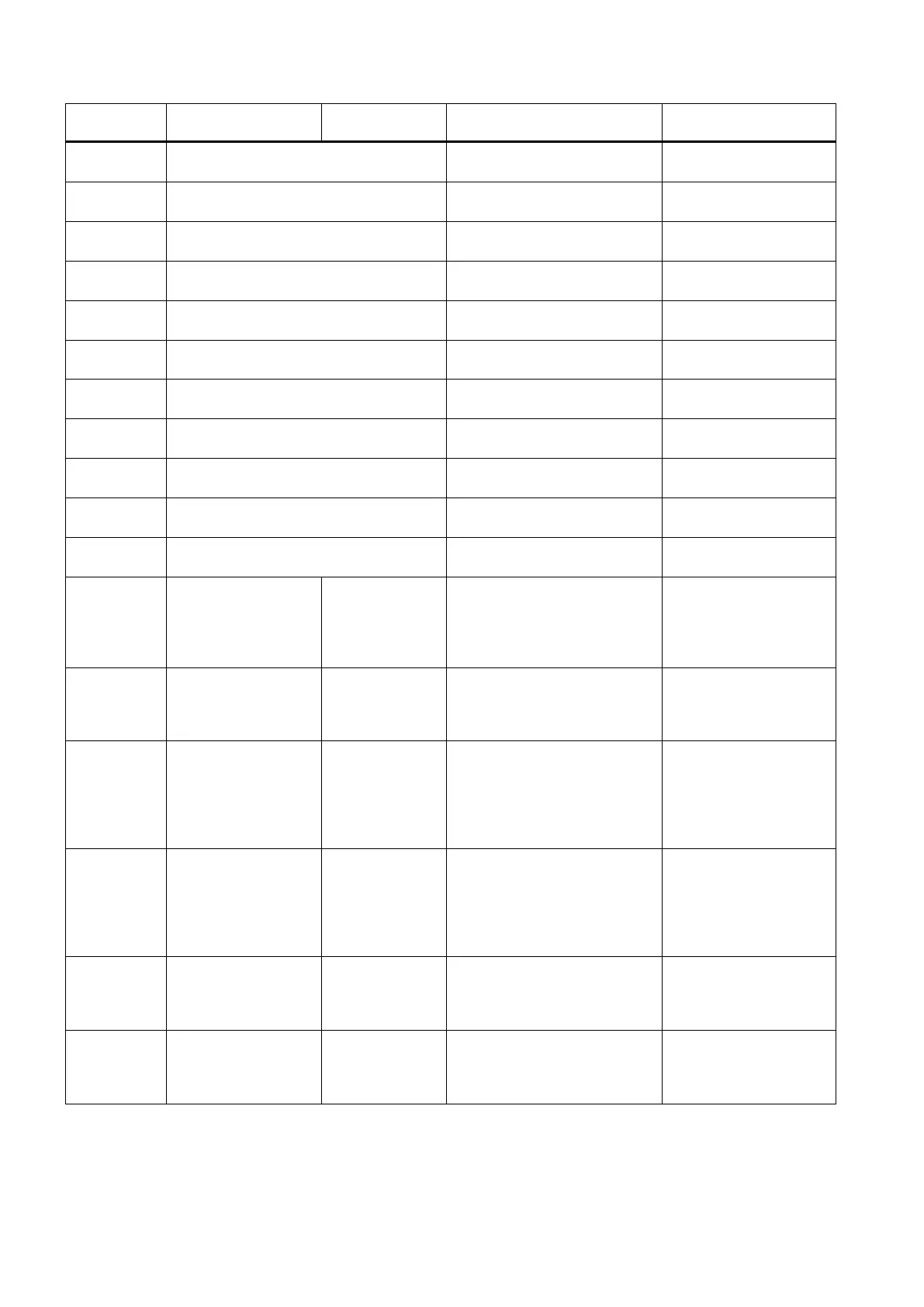

Programming and Operating Manual (Turning)

296 01/2017

CYCLE84 Rigid tapping N10 CYCLE84 (...)

CYCLE840 Tapping with compensating chuck N10 CYCLE840 (...)

CYCLE85 Reaming 1 N10 CYCLE85(...)

CYCLE86 Boring N10 CYCLE86(...)

CYCLE92 Cut-off N10 CYCLE92(...)

CYCLE93 Recess N10 CYCLE93(...)

CYCLE94 Undercut DIN76 (forms E and F), finishing N10 CYCLE94(...)

CYCLE95 Stock removal with relief cutting N10 CYCLE95(...)

CYCLE96 Thread undercut N10 CYCLE96(...); sepa-

CYCLE98 Side-by-side thread mounting N10 CYCLE98(...); sepa-

CYCLE99 Thread cutting N10 CYCLE99(...)

DC Absolute coordinate;

approach position

directly(for rotary axis,

spindle)

- It is also possible to specify the

dimensions for the end point of a

rotary axis with DC(...) irrespec-

tive of G90/G91; also applies to

N10 A=DC(45.3)

;Approach absolute posi-

tion of the A axis directly

N20 SPOS=DC(33.1);

DEF Definition instruction Defining a local user variable of

the type BOOL, CHAR, INT,

REAL, directly at the beginning

DEF INT VARI1=24,

VARI2 ; 2 variables of the

type INT ; name defined

DITS Run-in path

with thread G33

-1 ... < 0,

0,

> 0

Starting with configured axis

acceleration;

starting with sudden accelera-

tion;

run-in path specified, if neces-

N10 G33 Z50 K5 DITS=4

DITE Run-out path

with thread G33

-1 ... < 0,

0,

> 0

Braking with configured axis

acceleration.

Braking with sudden accelera-

tion,

specification of run-out path, with

rounding

N10 G33 Z50 K5 DITE=4

FRC Non-

chamfer/rounding

0, >0 When FRC=0, feedrate F will act For the unit, see F and

G94, G95;

for chamfer/rounding, see

FRCM Modal feedrate for

chamfer/rounding

0, >0 When FRCM=0, feedrate F will

act

For the unit, see F and

G94, G95;

for rounding/modal round-

Loading...

Loading...