Programming and Operating Manual (Turning)

01/2017

93

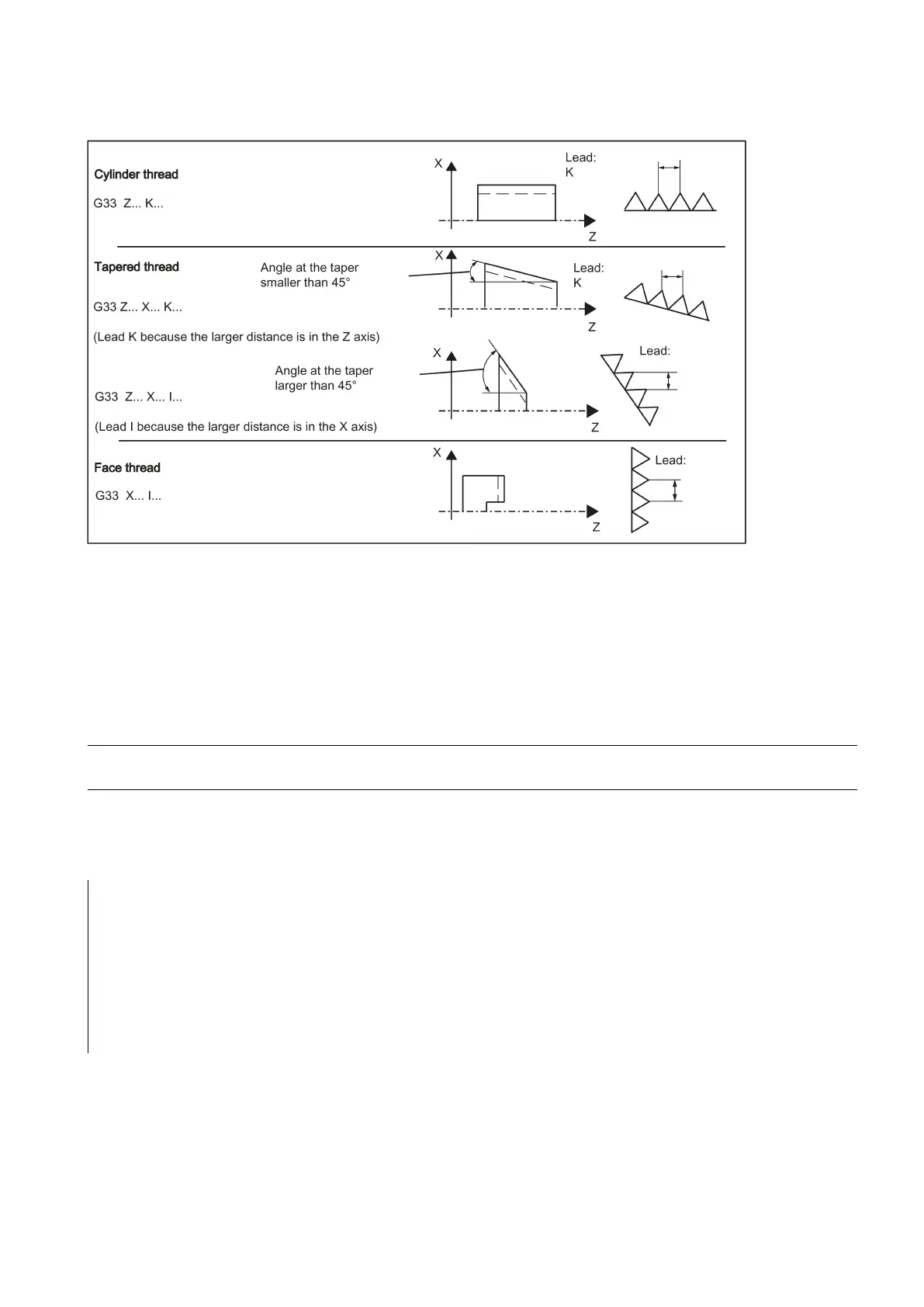

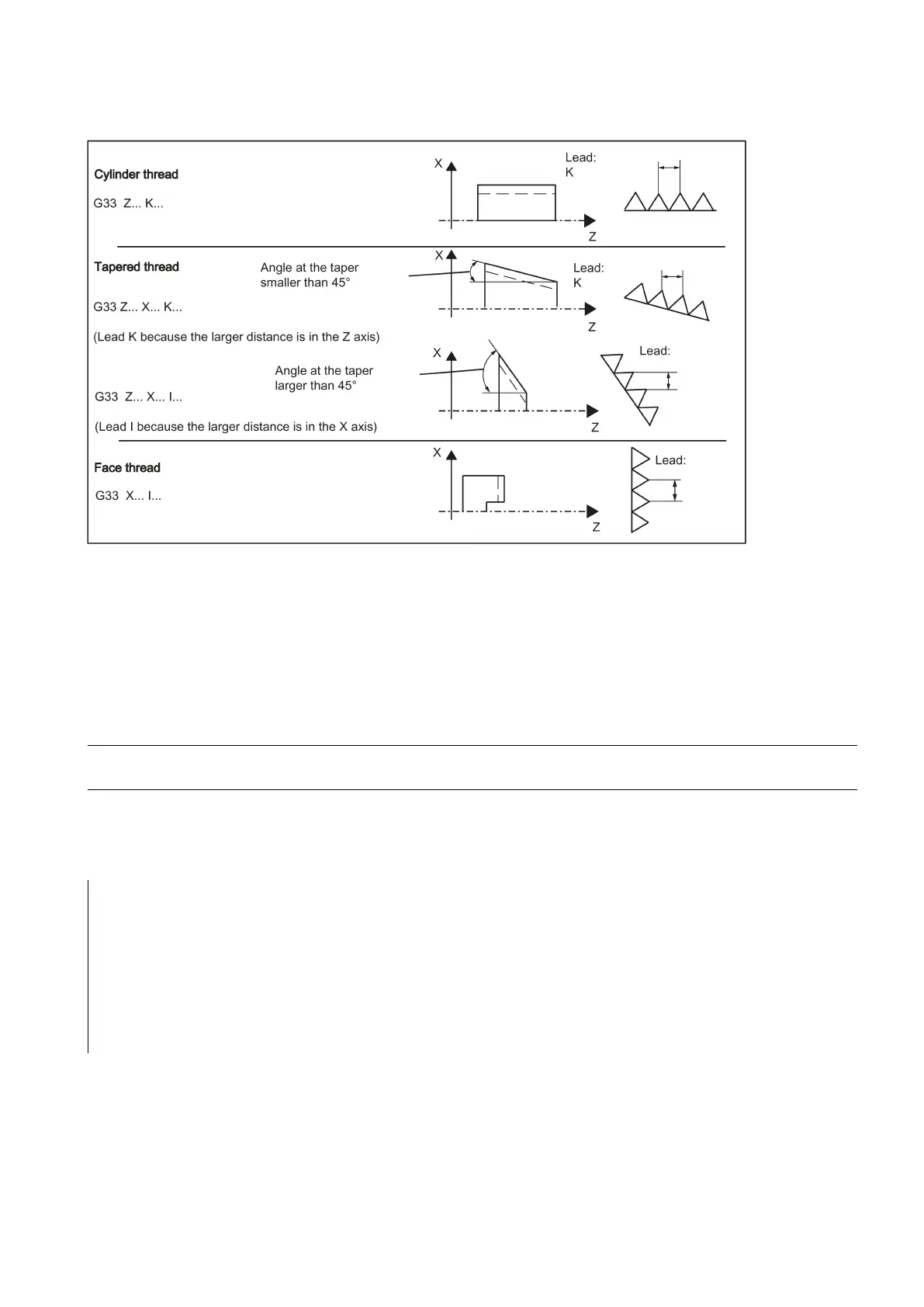

See the following illustration for lead assignment for cylindrical, tapered and face thread:

For tapered threads (2 axis values required), the corresponding lead address I or K of the axis with the

(longer

thread) must be used. A second lead is not defined.

Starting point offset SF=

A starting point offset is required for the spindle if a multiple-start thread or a thread in offset sections is to be machined. The

starting point offset is programmed in the thread block with G33 under the address

(absolute position).

If no starting point offset SF is written, the value from the setting data "Starting angle of thread" (SD42000:

THREAD_START_ANGLE) is active.

Note

A programmed value for SF must always be entered in the setting data.

Programming example

Cylindrical thread

, double-thread, starting point offset 180 degrees, thread length (including run-in and run-out) 100 mm,

thread lead 4 mm/rev.

N10 G54 G0 G90 X50 Z0 S500 M3

; Approach starting point, clockwise spindle rota-

tion

; 2nd thread, offset by 180 degrees

If multiple thread blocks are programmed consecutively (multi-block thread), it only makes sense to define a starting point

offset in the the first thread block.

Multi-block threads are connected automatically in G64 continuous path mode.

Loading...

Loading...