User Manual |

169

CNC Carving - 06 Maintenance

6.3 Every Month

6.3.1 Clean the Linear Modules

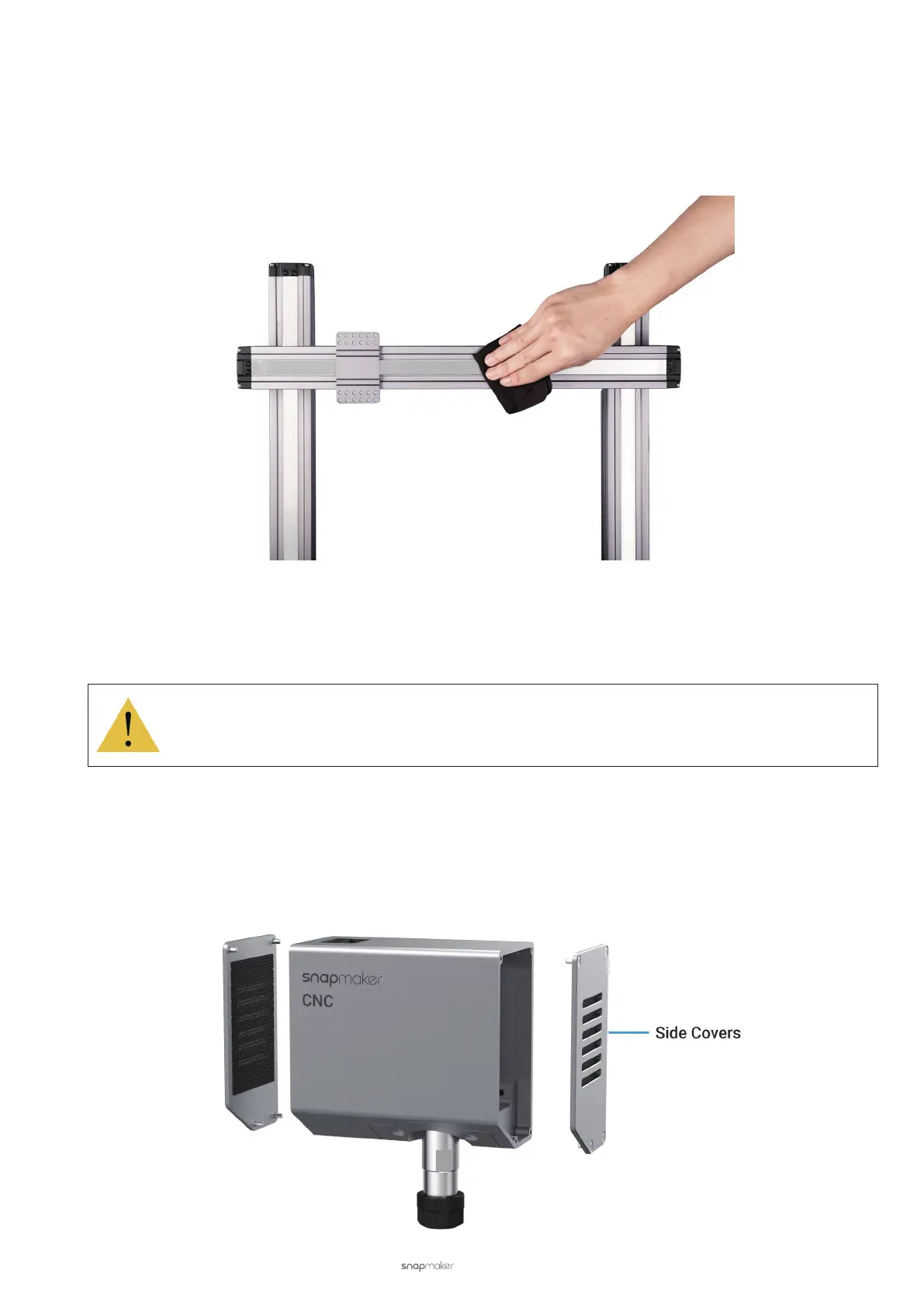

Keeping all Linear Modules free of dust and other foreign matters can reduce friction and noise while the CNC carver

is moving. To do so, gently wipe the Linear Module surface using a dry cotton cloth.

Usually, you should clean the CNC carver after each carving job. To always keep it free of sawdust, we recommend

you to give the machine a thorough cleaning, especially of the Base Plate, Y-axis Linear Modules, and Support

Platform.

While cleaning, do not press the steel strip.

Do not dismantle the Linear Modules yourself, as doing so will void Snapmaker’s Limited Warranty.

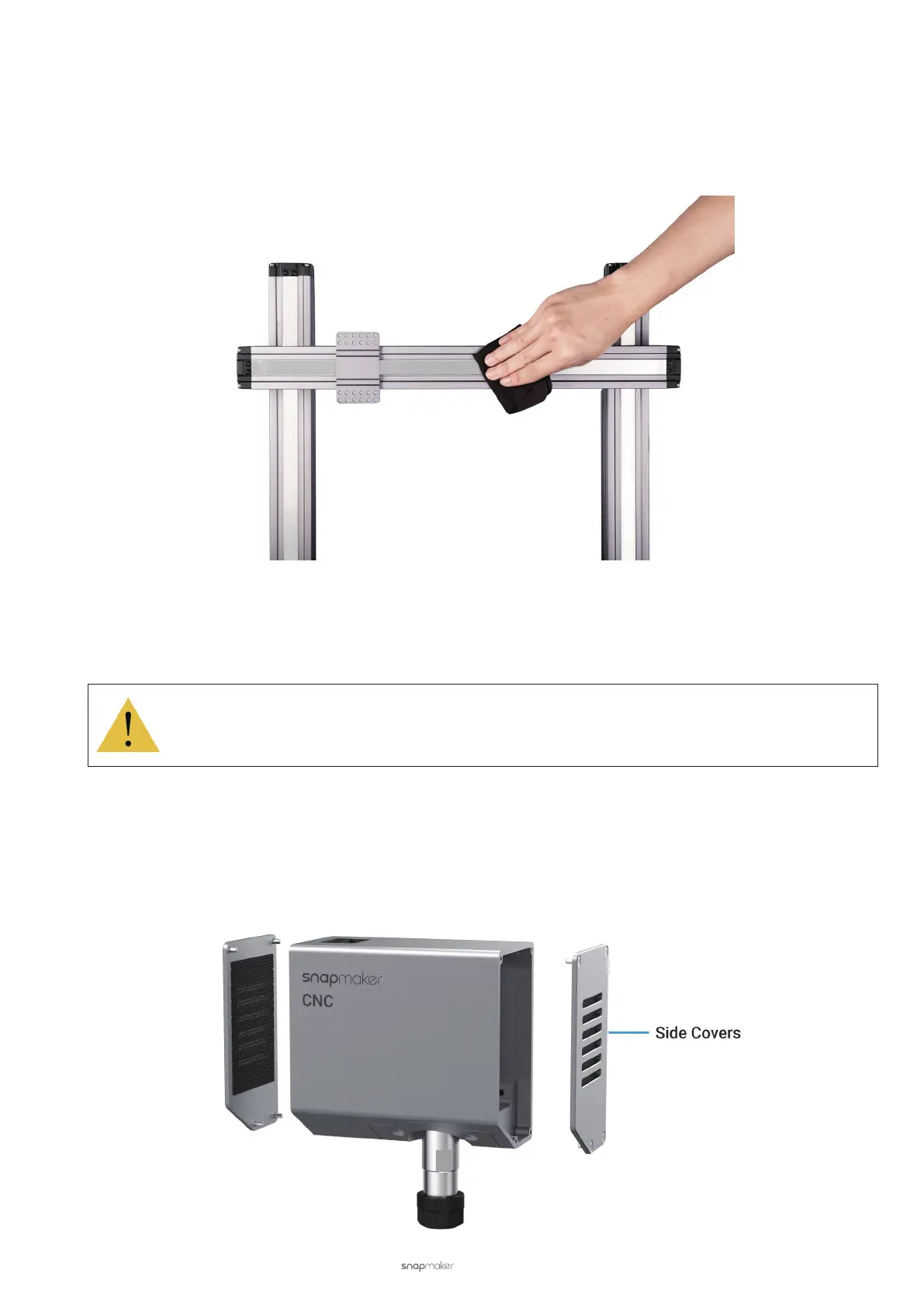

6.3.2 Clean the Side Covers

The CNC Carving Module has two side covers, each with vents and a dust-proof net for heat dissipation. If the side

covers are clogged by foreign matters, it will affect the airflow inside the 3D Printing Module. Consequently, the

internal components will be overheated, and the CNC Module will malfunction.

Loading...

Loading...