2-9 PERIODIC MAINTENANCE

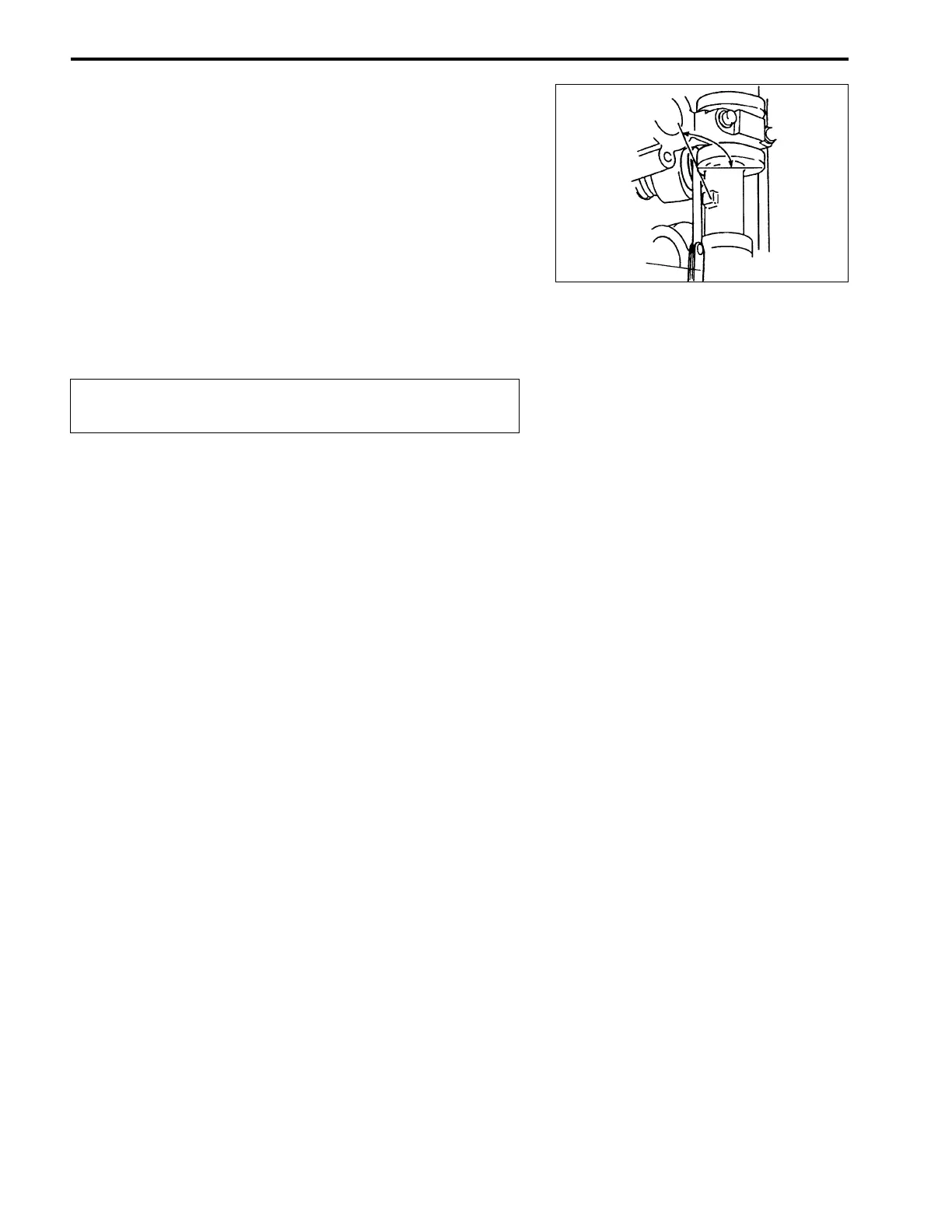

(5) Rotate crankshaft clockwise to bring cam nose vertical to

shim surface.

(6) Measure tappet clearances by inserting thickness gauge

between cam and shim surface.

Tappet clearance (cold engine condition) :

IN. : 0.18 – 0.24 mm (0.007 – 0.009 in.)

EX. : 0.18 – 0.24 mm (0.007 – 0.009 in.)

09900-20803 : Thickness gauge

B

Rotate crankshaft clockwise to prevent water pump

impeller damage.

NOTE:

•

Rotate crankshaft and measure clearance for each tappet

respectively by bringing cam nose vertical to shim surface.

•

All tappet clearances can be measured during two turns of

crankshaft.

(7) If out of specification, adjust tappet clearance by changing

shim.

90°

z

z

Loading...

Loading...