ENGINE CONTROL SYSTEM 3-18

FUEL PUMP CONTROL SYSTEM

OUTLINE

To supply the optimum fuel amount, the ECM controls the fuel pump drive duty cycle, a repeated ON/ OFF

signal, at a specified rate (1000 times a second).

Based on engine speed and battery voltage, the ECM determines the optimum duty (repeating “ON” time

rate within a cycle) and sends this signal to the fuel pump.

CONTROL MODE

BEFORE START :

For 3 seconds after ignition switch is turned “ON”, the pump is controlled to operate at 100% duty in order

to initially pressurize the high pressure line.

WHEN CRANKING :

The pump is controlled to operate at 100% duty.

WHEN RUNNING (NORMAL OPERATION) :

The pump is controlled to operate at 80 – 90% duty based on the current engine speed and battery voltage.

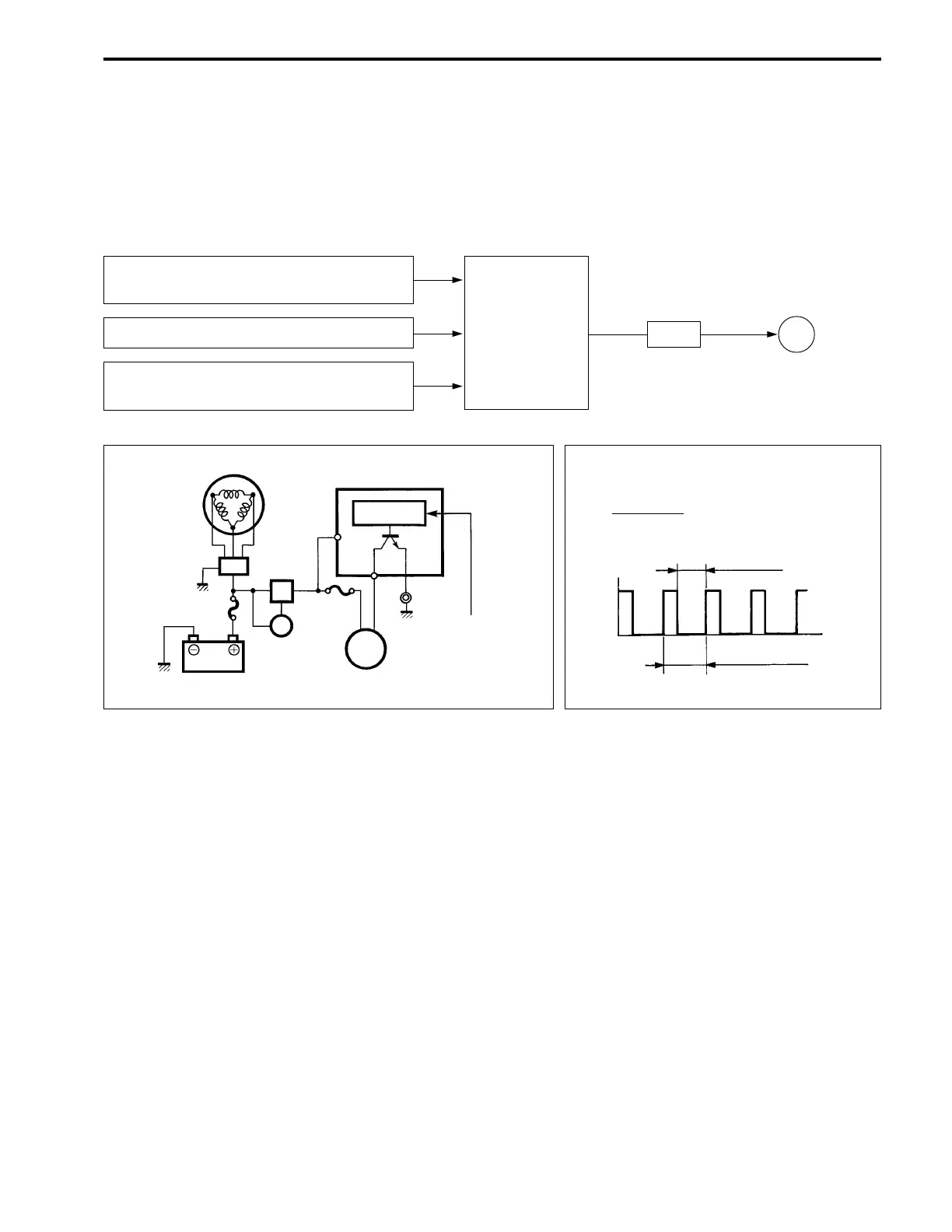

CKP sensor :

Informs ECM of engine speed.

Battery voltage :

Ignition switch :

Informs ECM of “START” signal.

ECM

Fuel pump

Signal

FP

ECM

CPU

Sensor / switch

signal input

FP

Fuel pump

15A

fuse

Ignition

switch

Battery

30A fuse

Rectifier &

regulator

Battery

charge

coil

ECM

main

relay

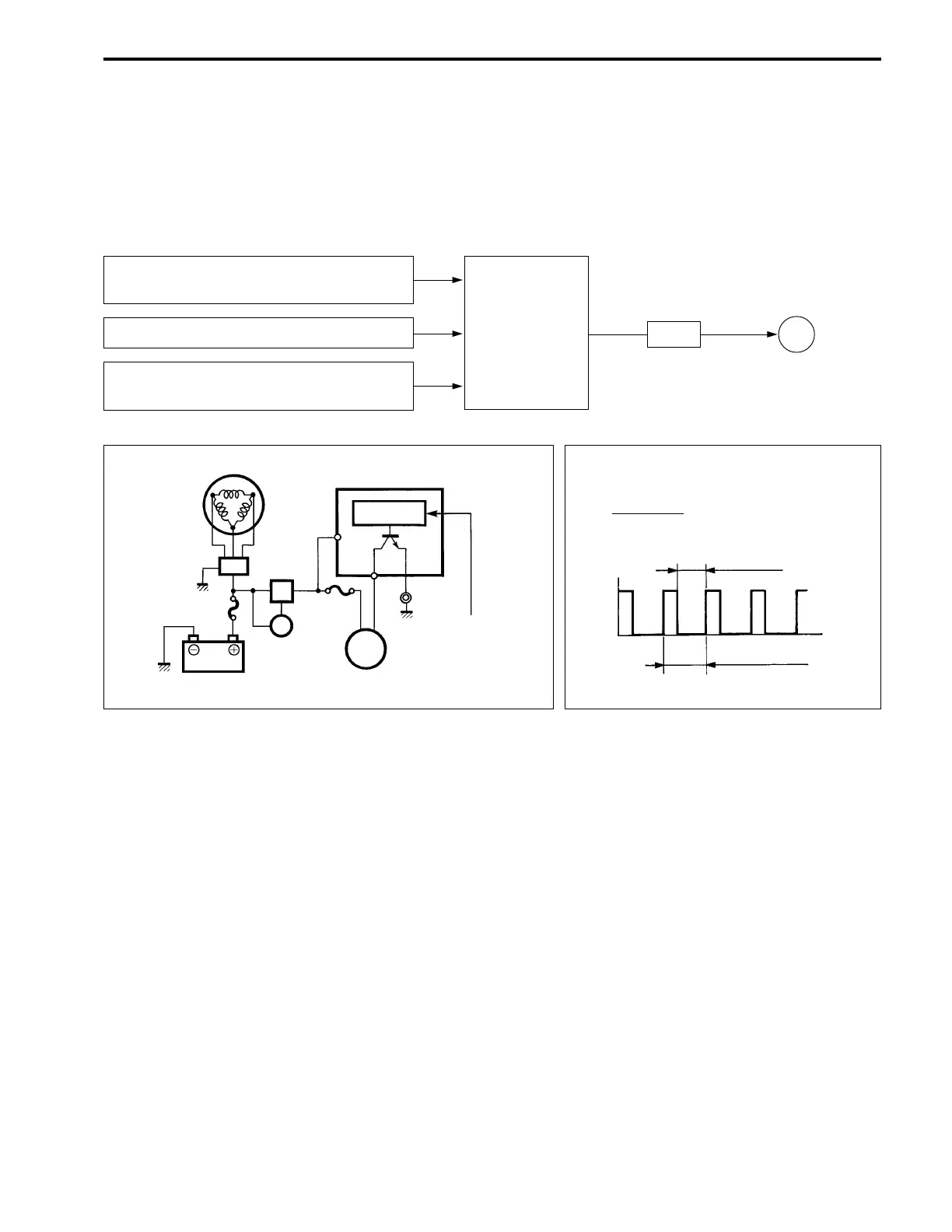

Duty cycle signal for fuel pump

(example : 80% duty)

“ON” time

1 cycle time

× 100 = duty (%)

OFF

ON

0.8 ms

Time

1 ms (1cycle)

Loading...

Loading...