ANTILOCK BRAKE SYSTEM (ABS) 5E-33

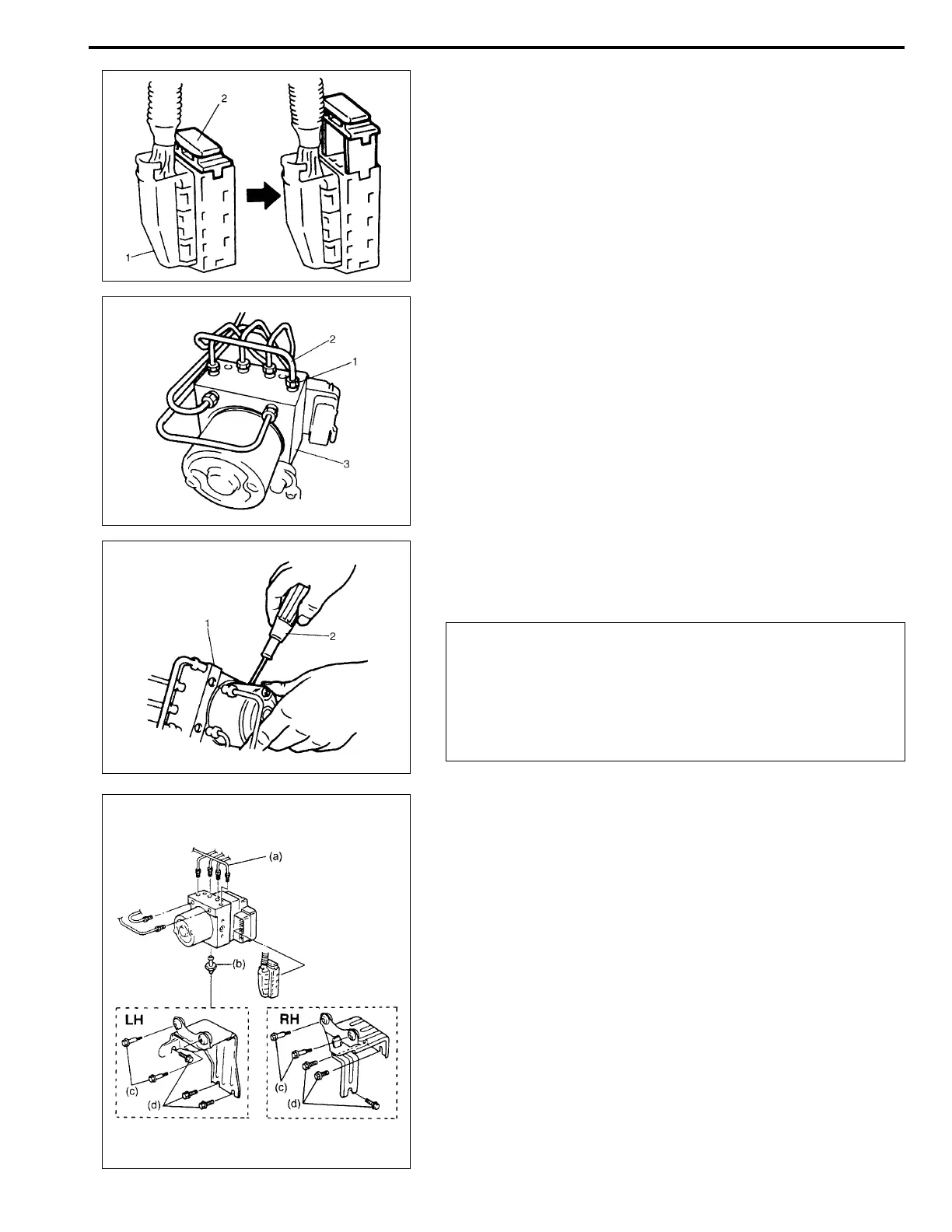

3) Disconnect ABS hydraulic unit/control module assembly con-

nector (1) by pulling up lock (2).

4) Using special tool, loosen flare nuts (1) and disconnect brake

pipes (2) from ABS hydraulic unit/control module assembly

(3).

Special tool

: 09950-78220

5) Remove two nuts and disconnect take out ABS hydraulic

unit/control module assembly (1) from bracket using screw-

driver (2).

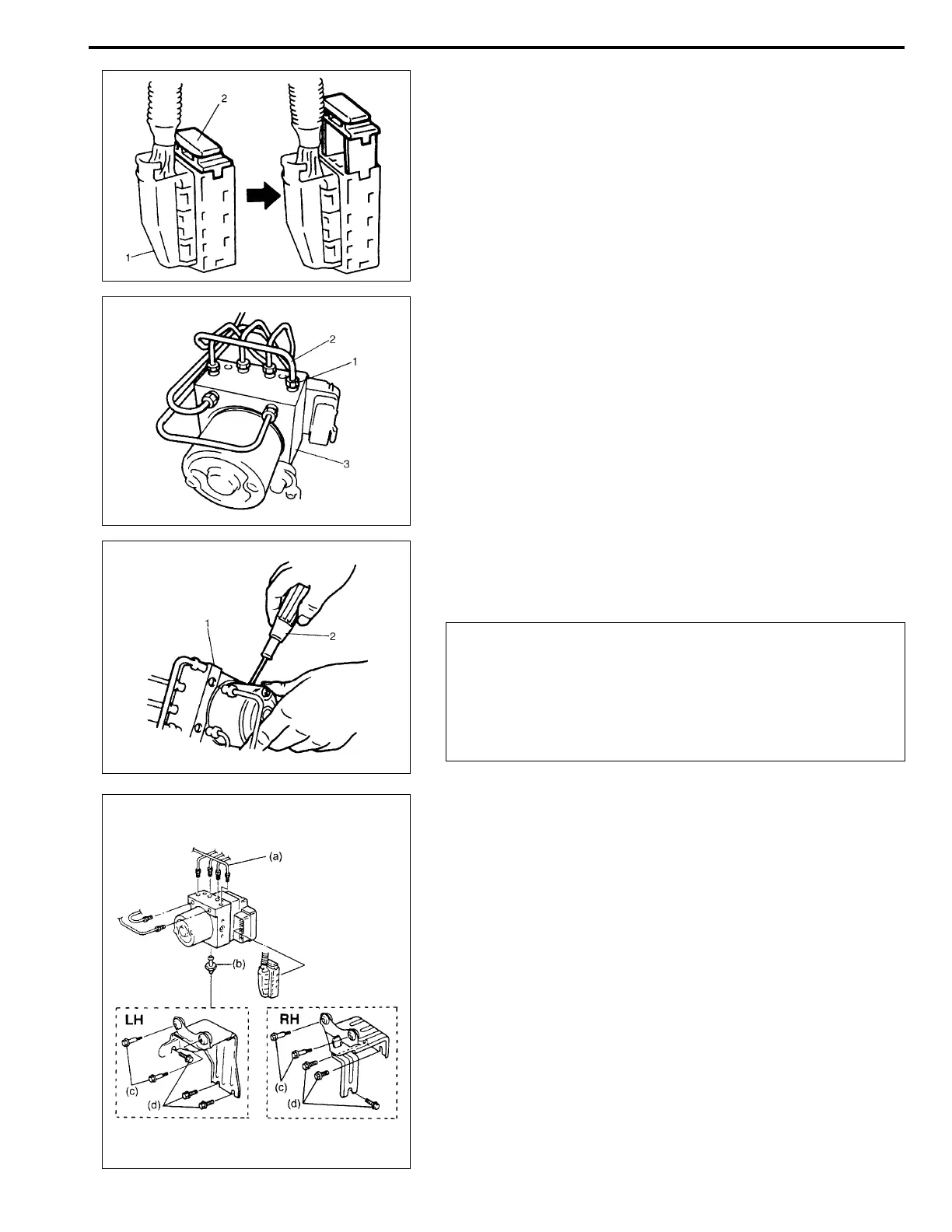

INSTALLATION

1) Install hydraulic unit by reversing removal procedure.

Tightening torque

(a) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

(b) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

(c) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

(d) : 26 N·m (2.6 kg-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “BRAKE” section.

3) Check each installed part for fluid leakage and perform “ABS

Hydraulic Unit Operation Check” in this section.

NOTE:

Put bleeder plug cap onto pipe to prevent fluid from spill-

ing. Do not allow brake fluid to get on painted surfaces.

CAUTION:

• Do not give an impact to hydraulic unit.

• Use care not to allow dust to enter hydraulic unit.

• Do not place hydraulic unit on its side or upside down.

Handling it in inappropriate way will affect its original

performance.

NOTE:

For new ABS hydraulic unit/control module assembly, if

“ABS Hydraulic Unit Operation Check” procedure has

not been performed, “ABS” warning lamp may flash

when ignition switch is turned ON position.

Loading...

Loading...