94

Tracking mark criteria

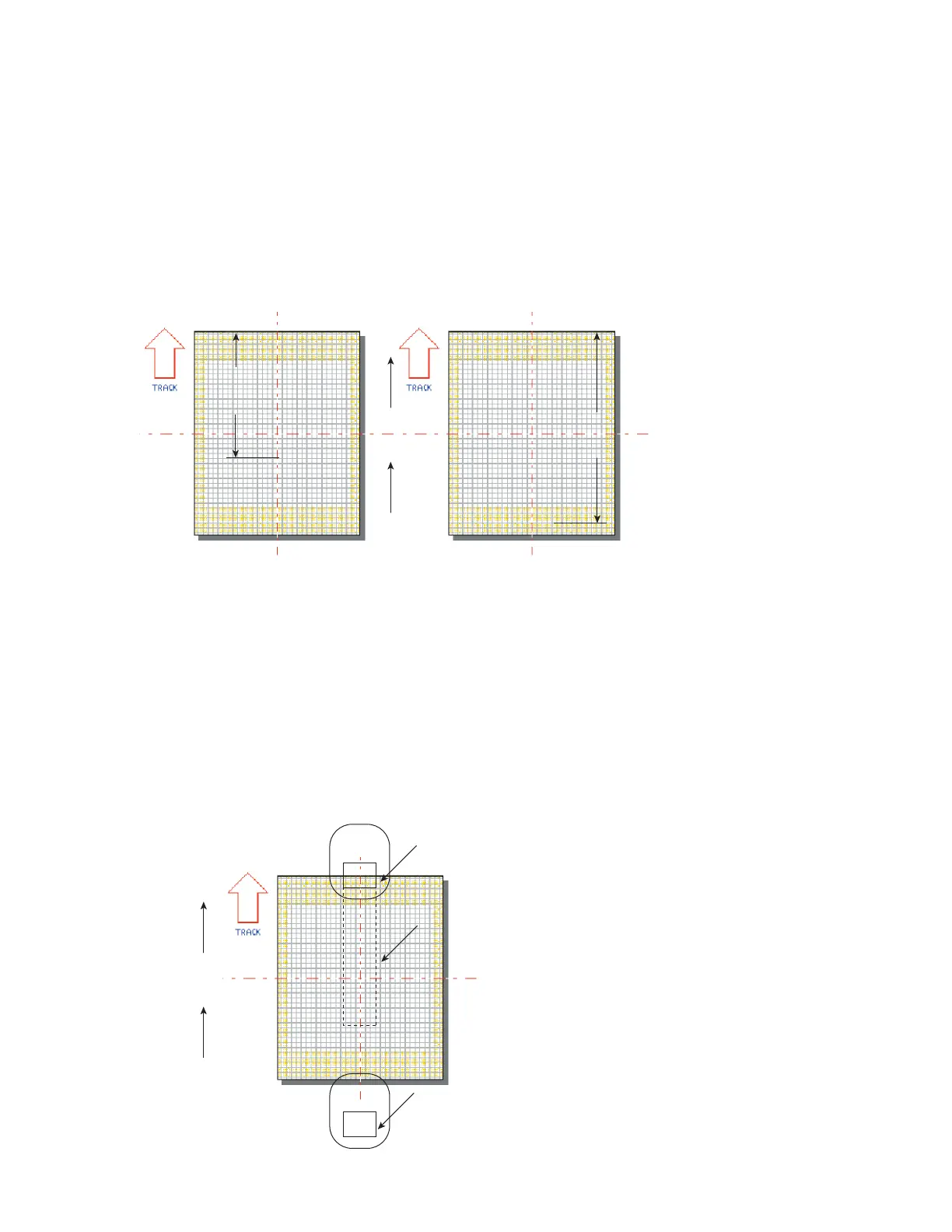

Mark position and orientation make a substantial dierence in tracking speed because they change

Usable Field Size. Maximum line speed is achieved when the Mark is positioned as close as possible

to the upstream edge of the Marking Window. The entire Mark must be positioned on WinMark

Pro’s Drawing Canvas so that it

lies within the boundaries of the Marking Window. Figure 5-8 shows

how the same text positioned differently can give two very different values for Usable Field Size.

Downstream Edge

Part

Motion

270°

Usable

Field

Size

ABCD1234

ABCD1234

Usable

Field

Size

Figure 5-8 Usable Field Size comparisons

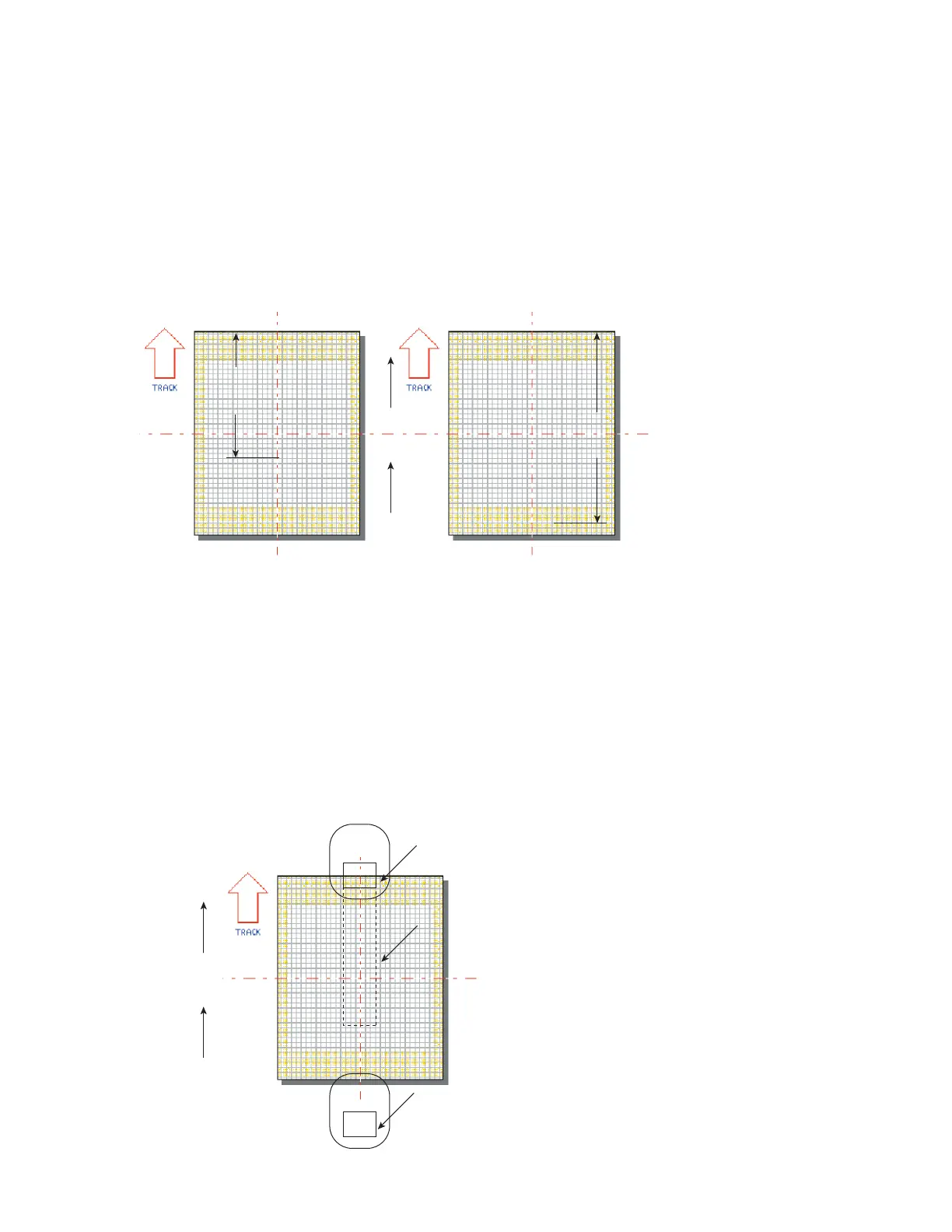

When the downstream edge of the Tracking Window coincides with the downstream edge of the Mark-

ing Window, then unmarked portions of the Target Area that move beyond the edge of the Tracking

Window are not marked and lasing stops.

If

part pitch constrains the downstream edge of the Tracking Window within the Marking Window, then

lasing continues until unmarked portions of the Target Area move outside the Marking Window, how-

ever the next part in the queue is not marked. In either case, the mark log displays a “Too fast to fin-

ish” error. In Figure 5-9, “Line 2” will mark unless unmarked areas move outside the Marking Window.

Figure

5-9 Maximum marking position in Tracking Window

SYNRAD FH Series Flyer Operator’s Manual Version 3.4

Part

270°

Line 1

Line 2

Line 1

Line 2

Target Area on Part

Tracking Window

Line 2 must finish marking

before any unmarked por

exit the Tracking Window

Loading...

Loading...