appendix a

230

SYNRAD FH Series Flyer Operator’s Manual Version 3.4

Cold Air Duct From

Cold Air Source

Side View

End View

Cooling

Mounting an auxiliary cooling fan

Use information in this section to mount an external cooling fan or cooling ductwork if you have deter-

mined that additional external cooling is required because (1) Flyer’s heat sink has less than 1.0" (25.4

mm) of free air space between the head and any enclosure or surface, (2) Flyer is oriented such that the

heat sink is pointing downward or in any other non-standard orientation, or (3) Flyer’s calculated internal

maximum temperature is higher than 50 °C.

Tests have shown that adding a cooling fan to provide airow over Flyer’s heat sink can reduce internal

temperatures by 10 °C in demanding marking applications. Choose a cooling fan with an airow rating of

at least 50–100 cubic feet per minute (CFM). For best results, mount the cooling fan or cooling ductwork

at an angle of approximately 15° to the heat sink so that airow is directed slightly upward. The natural

tendency of heat to rise will assist in the heat removal process. See the example drawing in Figure A-2.

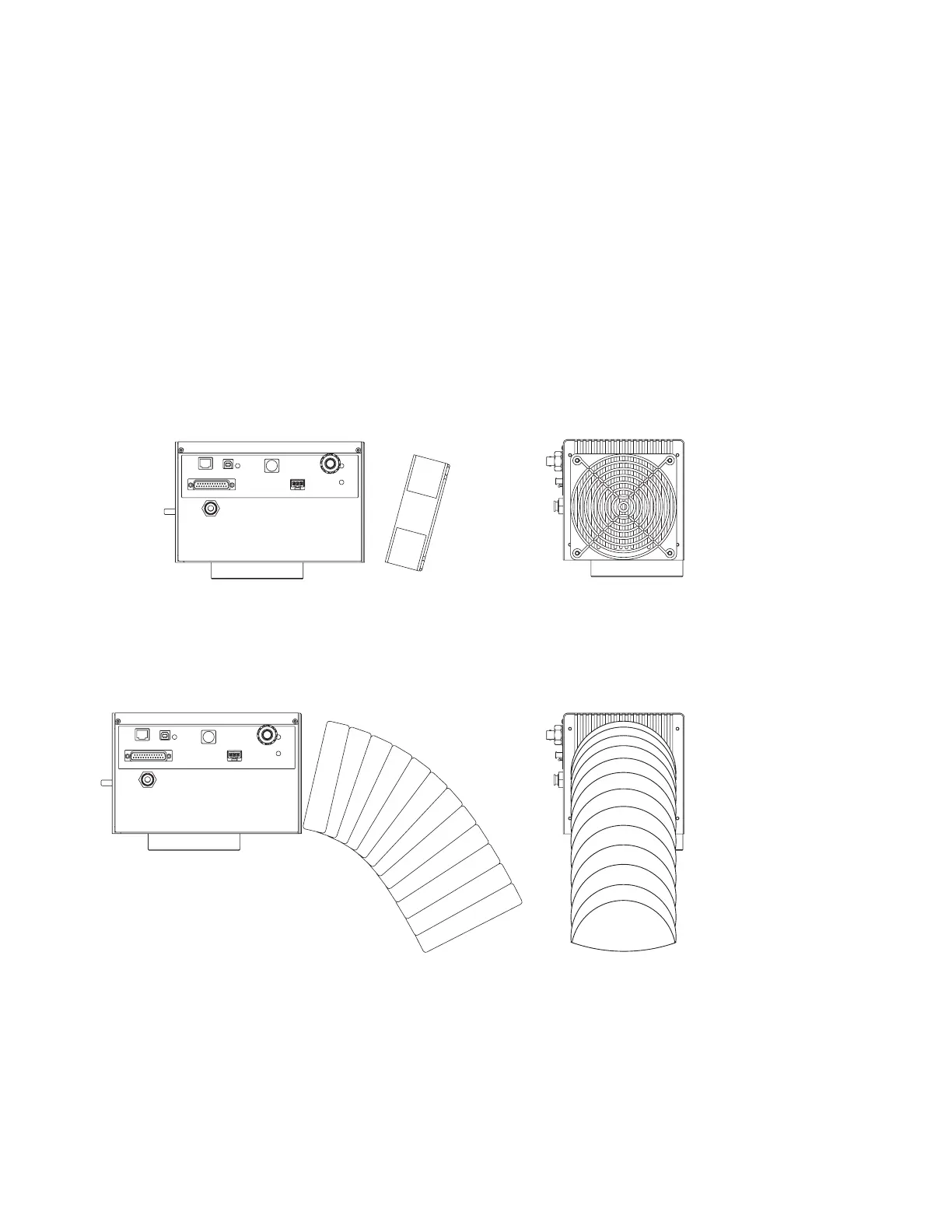

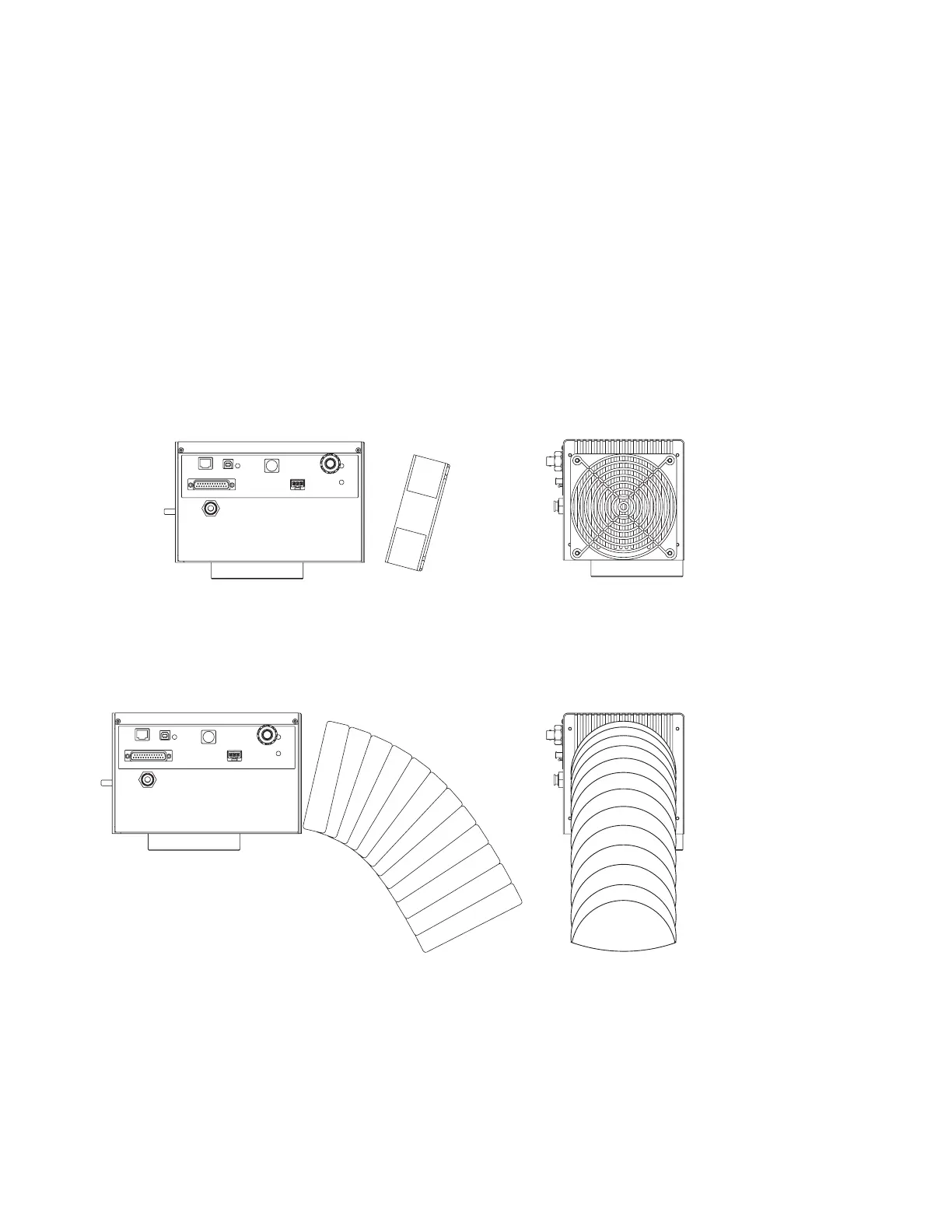

Figure A-2 Mounting cooling fan or ductwork to Flyer

Before mounting a cooling fan or ductwork, refer to Figure 5-20 in the Technical Reference chapter for a

diagram showing dimensions

of the four user-accessible mounting holes in Flyer’s heat sink. The mounting

holes are tapped for standard 6–32 UNC screws with a maximum depth of 0.25" (6.35 mm).

Loading...

Loading...