SYNRAD FH Series Flyer Operator’s Manual Version 3.4

100

Tracking hardware

Part sensor

When tracking, a part sensor is required to send ‘start mark’ signals to the Flyer marking head on input

IN0 (unless you enable the Internal Part

Trigger property and specify a Part Pitch value). Any number of

capacitive, inductive, photoelectric, or mechanical sensors currently on the market can be used

depending on the part’s material composition and your marking environment. Table 5-2 lists electrical

specifications for choosing a part sensor.

Table 5-2 Part sensor specifications (for IN0)

Function Specications

Input Voltage User determined (+15.0 VDC if powered from Flyer’s internal 15 V supply)

Output Signal Open collector (PNP or NPN) or open drain (P-channel or N-channel)

or debounced mechanical limit switch

Low level output voltage: –1.0 V to +1.0 VDC (0 V typ.)

High level output voltage: +3.0 V to 24.0 VDC

On-state current: 6 mA typical; 9 mA maximum at 5 VDC

16 mA typical; 23 mA maximum at 12 VDC

20 mA typical; 29 mA maximum at 15 VDC

32 mA typical; 47 mA maximum at 24 VDC

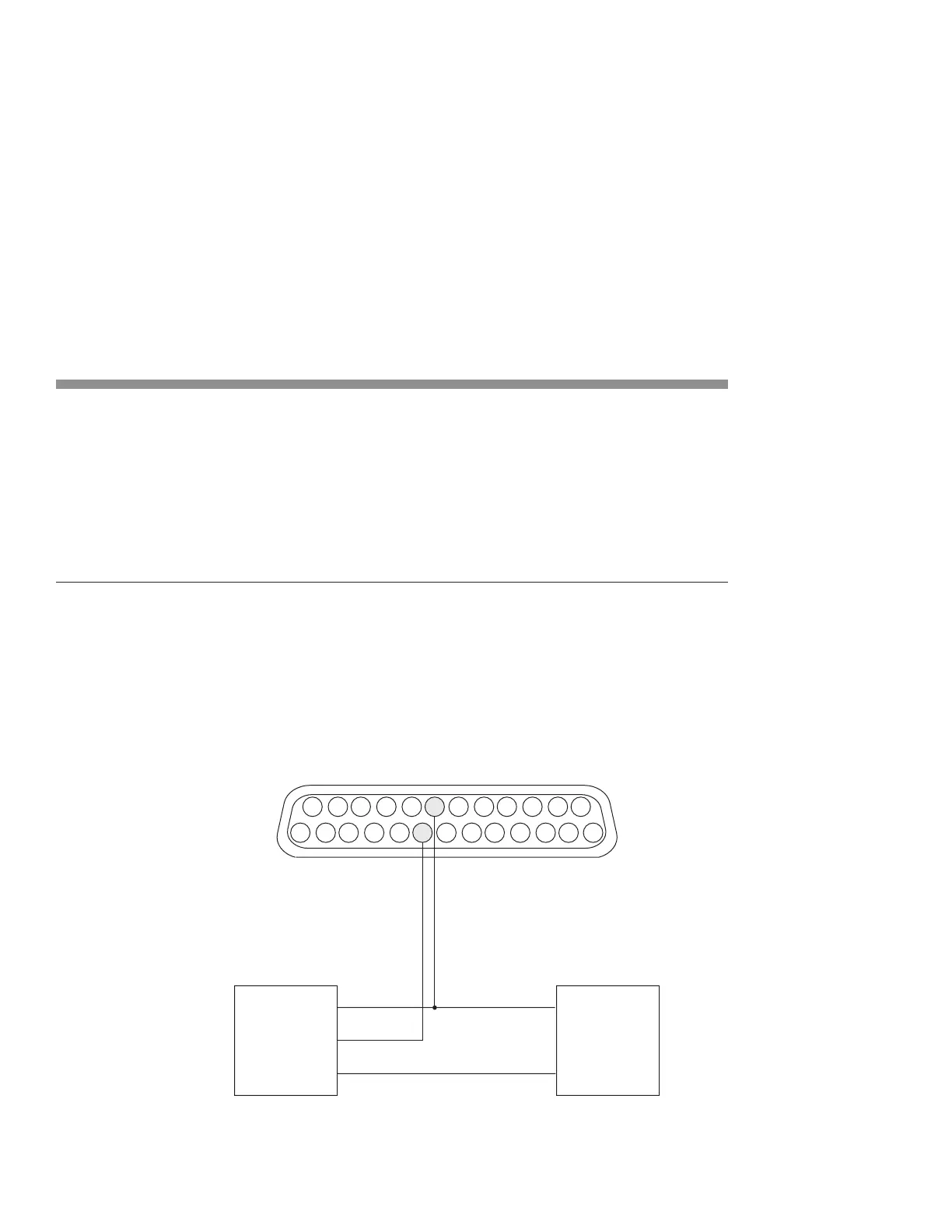

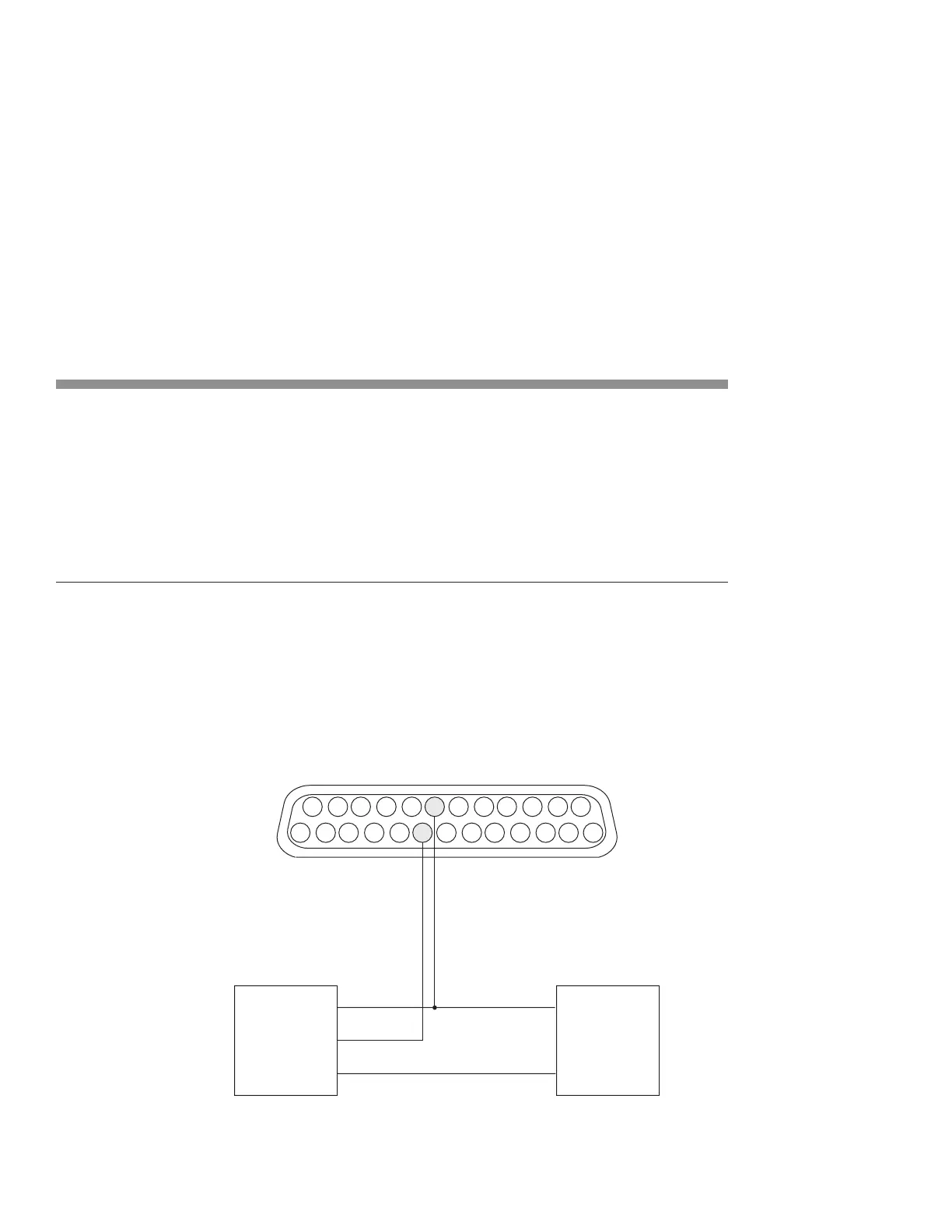

Part sensor connection

The part sensor output is connected directly to input IN0 on FH Flyer’s User Interface connector. To con-

nect

the part sensor, refer to the appropriate connection diagram. Figure 5-15 shows a customer-

supplied power supply driving a current-sinking NPN open collector part sensor. Figure 5-16 shows how

to power the same type sensor from Flyer’s built-in +15 VDC power supply. See Figure 5-17 and 5-18

when wiring current-sourcing PNP open collector part sensors.

25

24

15

14

13

12

2

1

DC POWER SUPPLYPA RT SENSOR

V+

GND

V+

OUT

GND

8

IN0_A

IN0_B

20

Figure 5-15

Wiring diagram for current-sinking (NPN open collector) part sensors

Loading...

Loading...