technical reference

SYNRAD FH Series Flyer Operator’s Manual Version 3.4

145

Name RJ45 Pin # Cable Color RJ45 Pin # Name

TX+ 1 White/Orange 3 RX+

TX– 2 Orange 6 RX–

RX+ 3 White/Green 1 TX+

n/c 4 Blue 4 n/c

n/c 5 White/Blue 5 n/c

RX– 6 Green 2 TX–

n/c 7 White/Brown 7 n/c

n/c 8 Brown 8 n/c

n/c — not connected

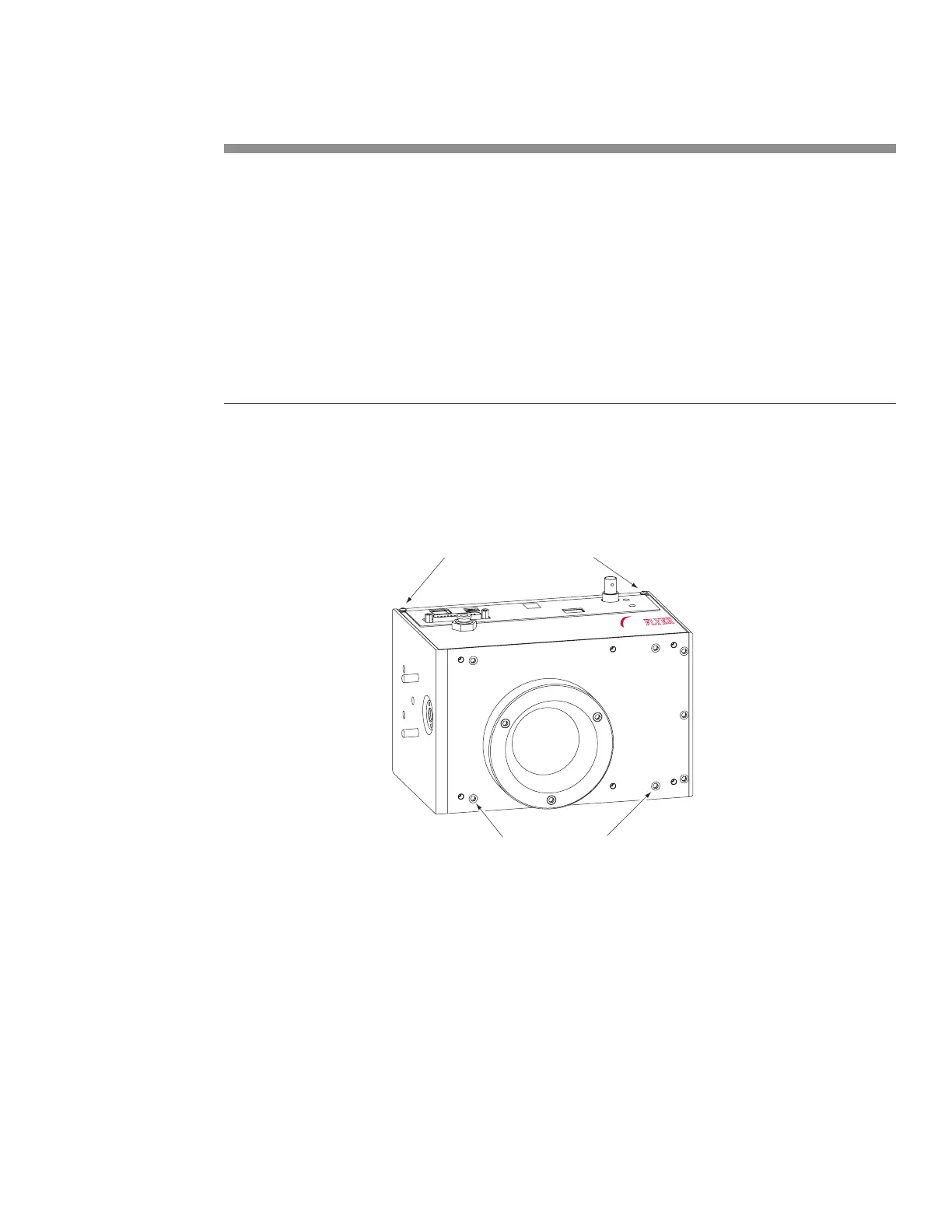

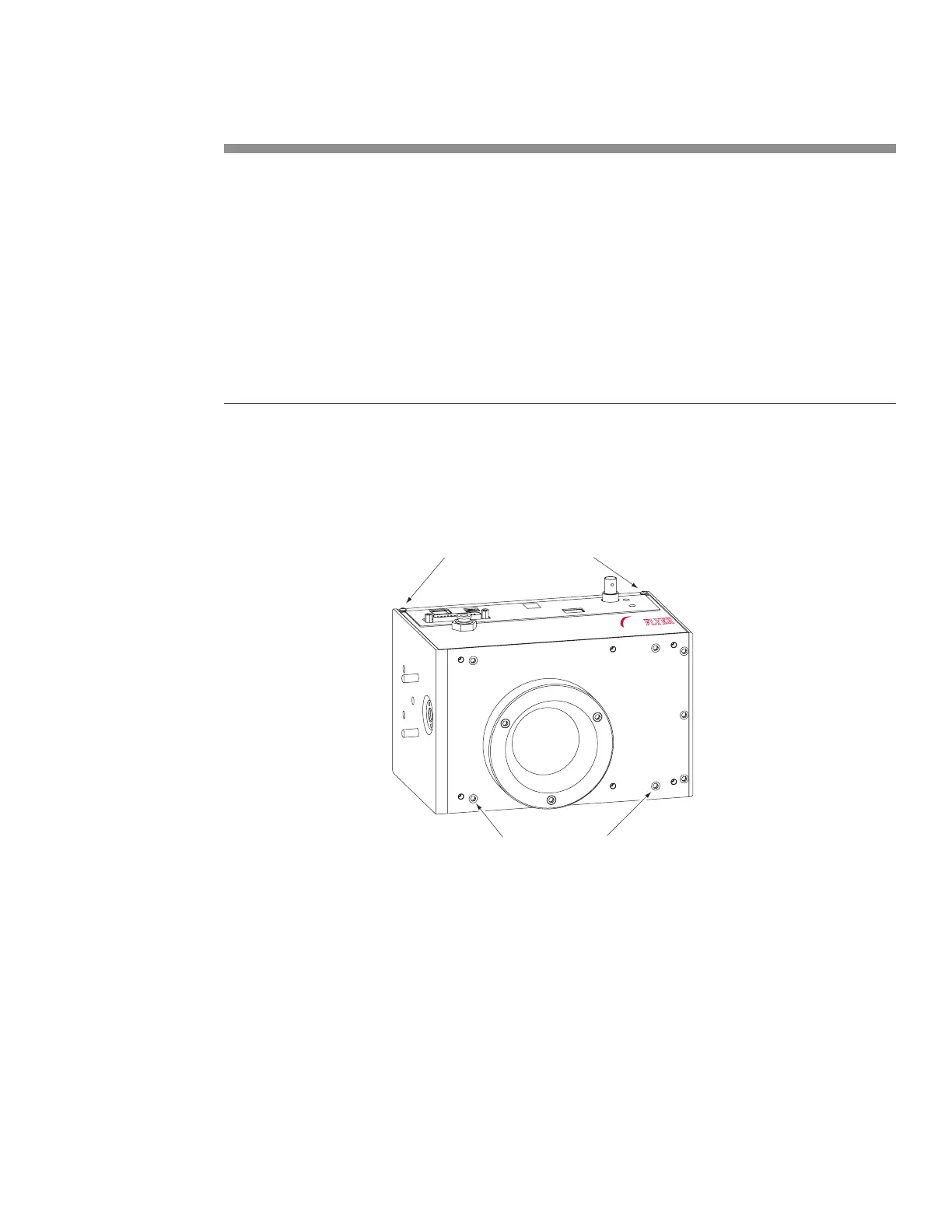

Figure 6-13 shows the physical wiring for crossover Ethernet cable.

TEST

MARK

POWER

LASER

CONTROL

STATUS

PWR

USB

USER INTERFACE

ETHERNET

Remove two button head screws

Remove two capscrews

FH

MARKING HEAD

FLYER

Figure 6-13 Physical wiring—crossover Ethernet connection

Fast Acting Safety Interlock

Many marking applications require a safety action to occur for each part that is marked. An example of

this action is a machine that lowers a shield over a part prior to marking, and then raises the shield to

advance the part as soon as the mark is complete. SYNRAD lasers are equipped with a Remote Interlock

feature that disables laser ring, typically when a safety switch on an access door or enclosure is opened.

However in marking applications where a safety interlock is frequently cycled, the Remote Interlock may

create an unacceptable delay. This delay occurs because closing the interlock (and cycling the Keyswitch,

or remote keyswitch, on Keyswitch-equipped lasers) invokes a built-in ve-second delay prior to lasing.

Loading...

Loading...