SYNRAD FH Series Flyer Operator’s Manual Version 3.4

146

LASER

ROL

STATUS

1

2

3

4

1

2

3

4

SW1

SW2

Move switch 1 on switch bank SW1

to the “ON” position to enable FASI

SW1

SW2

1

2

3

4

1

2

3

4

ON – OFF

ON – OFF

To address this issue, FH Flyer marking heads incorporate a Fast Acting Safety Interlock (FASI) function.

The FASI function prevents Flyer from generating a PWM Command signal unless an active input is pres-

ent on input IN3. When an enable signal is applied, FH Flyer responds to the rising edge transition in less

than 1 millisecond (ms).

Important Note: The Fast Acting Safety Interlock (FASI) function does NOT disable the laser. FASI

only prevents FH Flyer from sending PWM Command signals to the laser. Flyer still

sends tickle pulses (1 µs @ 5 kHz) out the Laser Control port in order to maintain

plasma ionization inside the laser.

To enable Flyer’s FASI feature, refer to Figure 6-14 and perform the following steps:

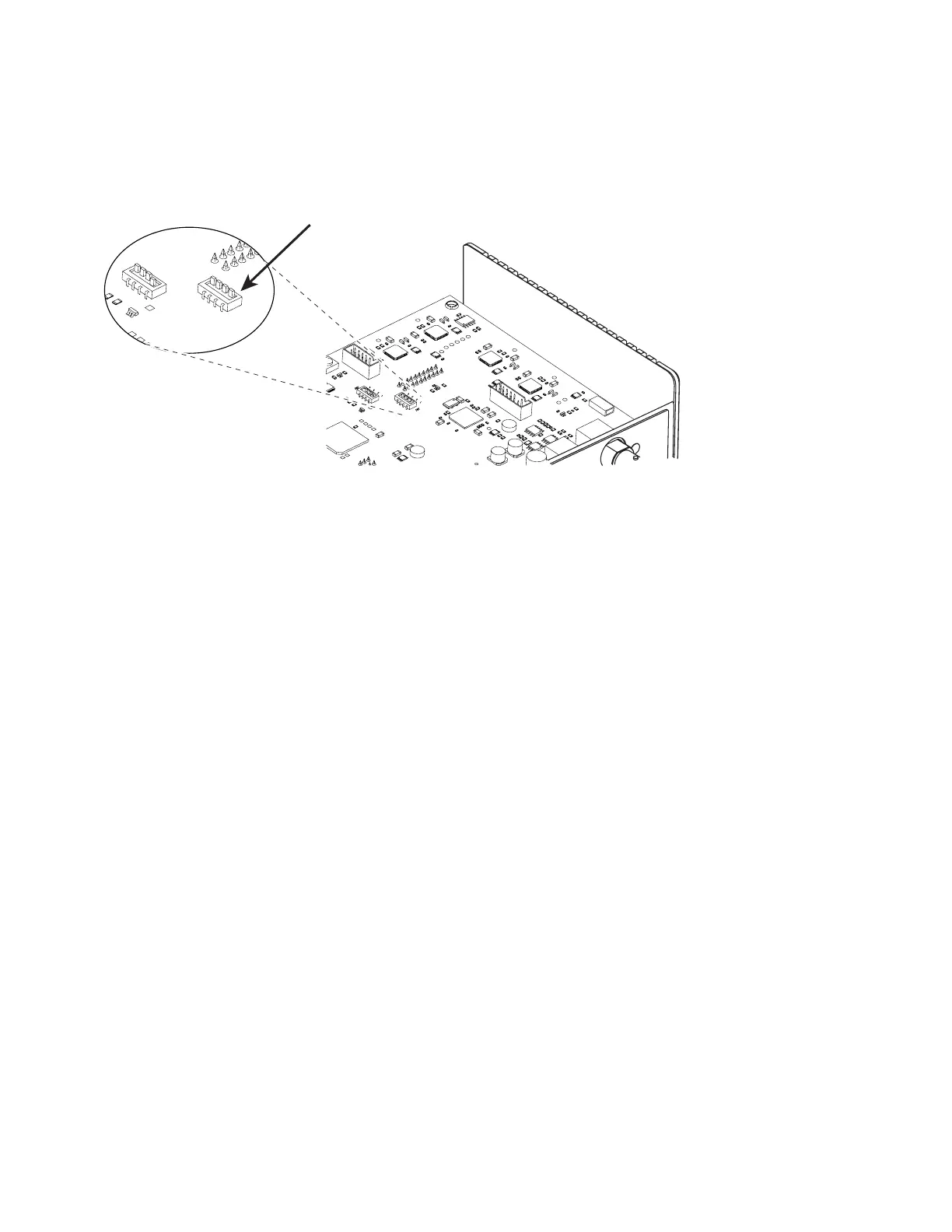

Figure 6-14 Opening Flyer to enable FASI

1

Remove DC power from the Flyer head or disconnect the DC Power cable.

2

Refer to Figure 6-14 and withdraw two button head Allen screws and two Allen head capscrews

at the locations shown to remove Flyer’s upper cover.

3

Ground yourself by keeping one hand in constant contact with Flyer’s lower metal cover.

4

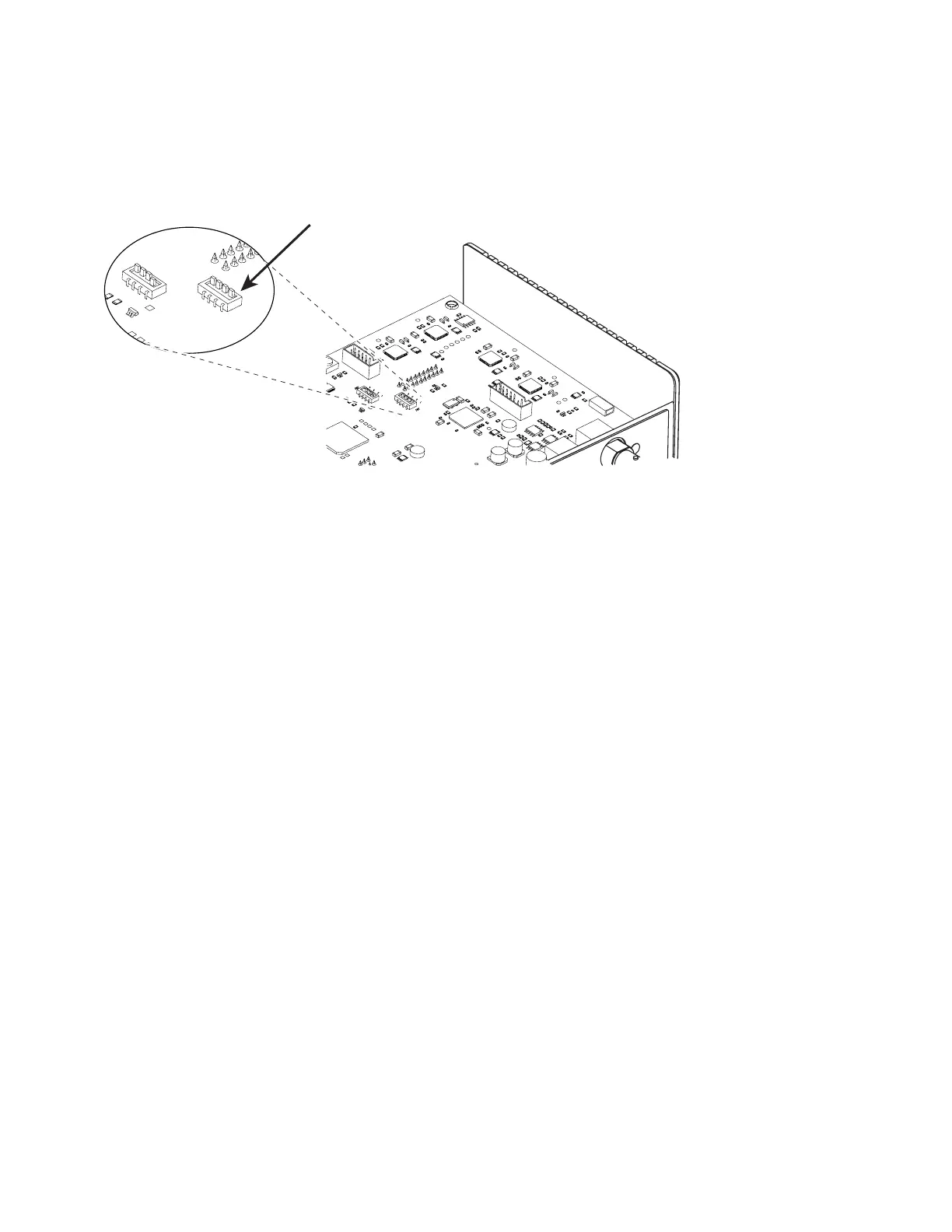

Locate the DIP switch bank labeled SW1 on the CPU board (see Figure 6-15) and move switch #

1 to the “ON” position.

Fast Acting Safety Interlock

Figure 6-15 Flyer DIP switch locations

5

All other switches must remain at their default settings as listed on Table 5-21 below.

6

Replace Flyer’s upper cover and tighten the screws removed in Step 2.

7

Open your mark les and congure WinMark’s Wait Digital Before Piece automation command to

wait for a “Set” state on input IN3 before marking begins. This step synchronizes marking operations

with the FASI safety feature.

8

To begin lasing with FASI enabled, apply a 5–24 VDC signal to Flyer input IN3.

Loading...

Loading...