INSTRUCTION MANUAL

8

3.1. INTRODUCTION

The construcon of the unit consists of the covers, collaring machine body, spindle, a

clamping mechanism and posioning table.

The machine body and the spindle absorb the collaring stress. The feed stroke of the

spindle is servo controlled, which assures the achievement of an opmal eciency and a

great precision. The spindle rotaon is accomplished by means of a ming belt, directly

by the driving motor.

The S-80 collaring machine has safety devices in accordance with the CE requirements.

All this to guarantee that the T-DRILL S-80 unit is reliable even in heavy duty industrial

use.

3.2. THE PURPOSE OF THE MACHINE

The S-80 unit is designed for extrusion of collars to straight and bent tubes (using the

Manual feed table).

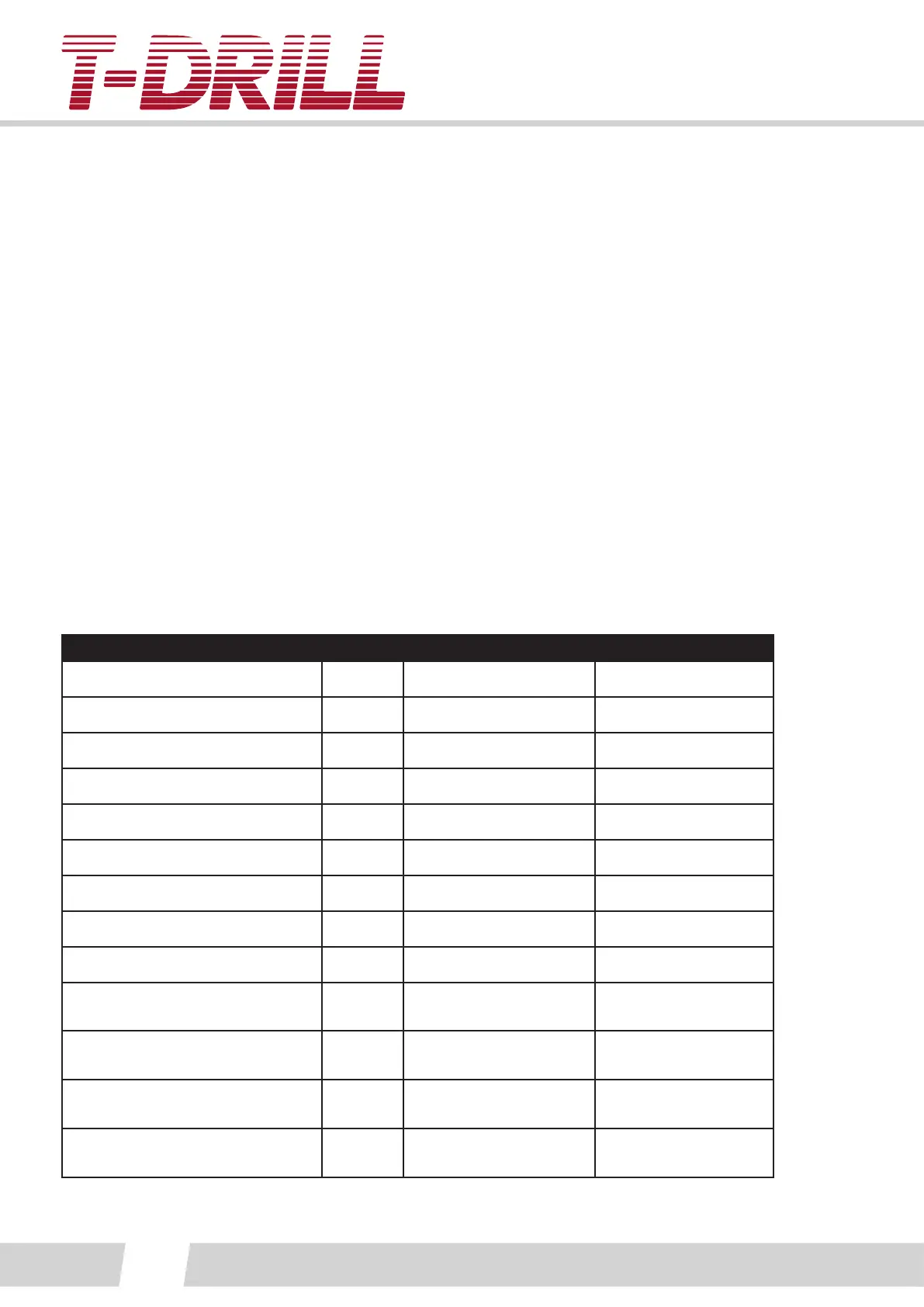

3.3. TECHNICAL SPECIFICATIONS

Type Unit S-80 collaring machine NOTE!

Type code 40231 Manuf. no. 118028

Max. run tube O.D. mm 114,3

Max. collar O.D. mm 88,9

Max. wall thickness of run tube mm 3.05 SCH10

Compressed air supply bar 6

Compressed air consumpon l/min 70

Connected power kW 5 see machine plate

Fuse sizes A 3 x 32 A (max)

Operang voltage 3 x 400 V / 50 Hz see machine plate

Weight of the unit kg 2200

Weight of the electric cabin kg 110

Weight of the machine cover kg 330

Front cover (with trash drawer) kg 150

1 bar = 100 kPa

Loading...

Loading...