BRAKES

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

105

Do NOT use a commercial brake cleaner unless the

entire brake has been disassembled.

Remove any accumulated brake dust with a brush.

Remove the brake shoes. See ’Brake Shoe and Adjuster

Replacement’.

Clean backing plate with a commercial brake cleaner.

Allow to dry completely.

It is important that the friction areas between the

backing plate and the brake shoes be lubricated. Be

careful not to allow lubricant to contact the braking

portion of the brake shoes or the friction surface of

the brake drum. Use only recommended lubricants.

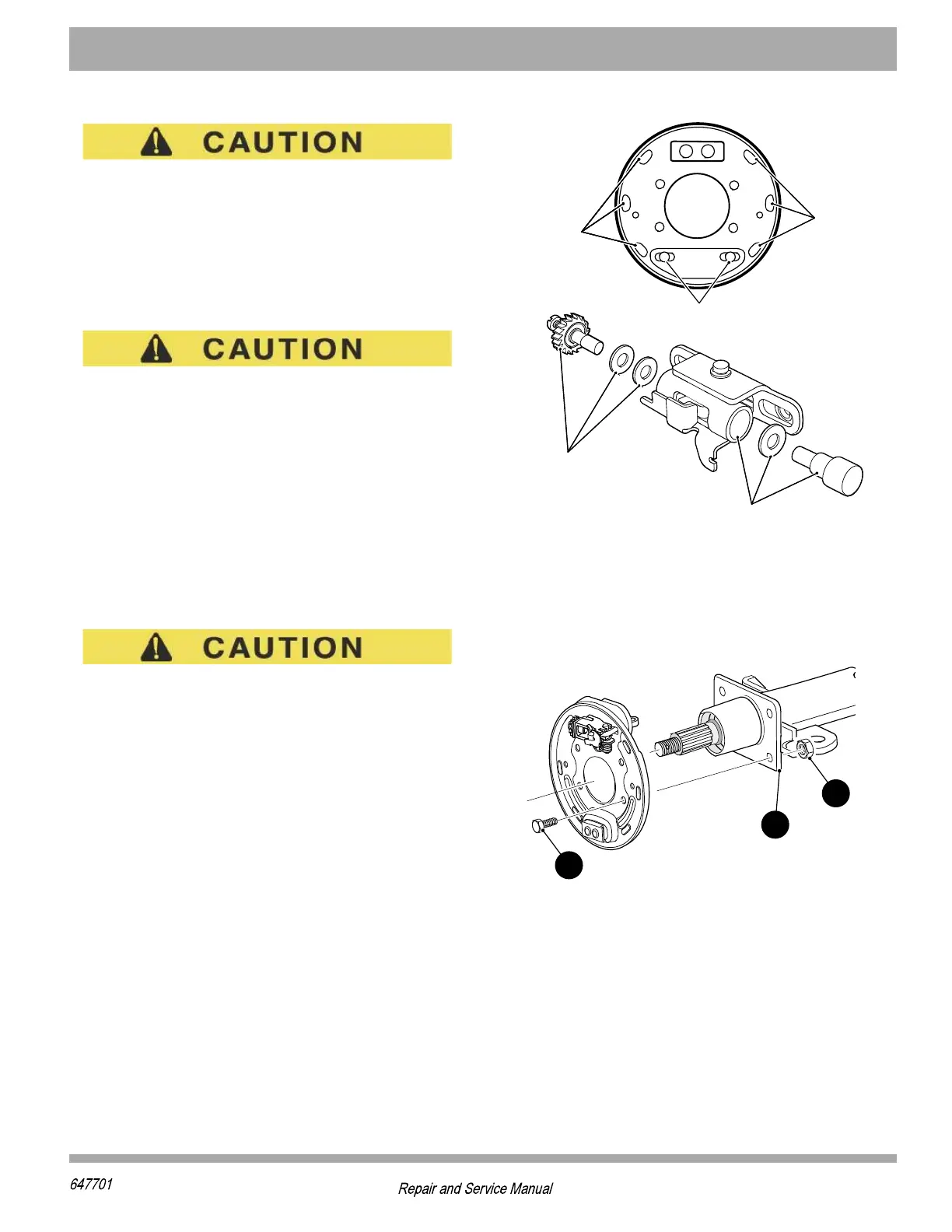

Lubricate the backing plate friction points of the shoes

and moving anchor with Multi Purpose Grease (MPG)

lubricant (Figure 12).

Install the actuator components, adjuster components

and brake shoes. See ’Brake Shoe and Adjuster

Replacement’ If the brake shoes and drum are not to be

replaced, sand the friction surfaces lightly with emery

cloth to remove any foreign material.

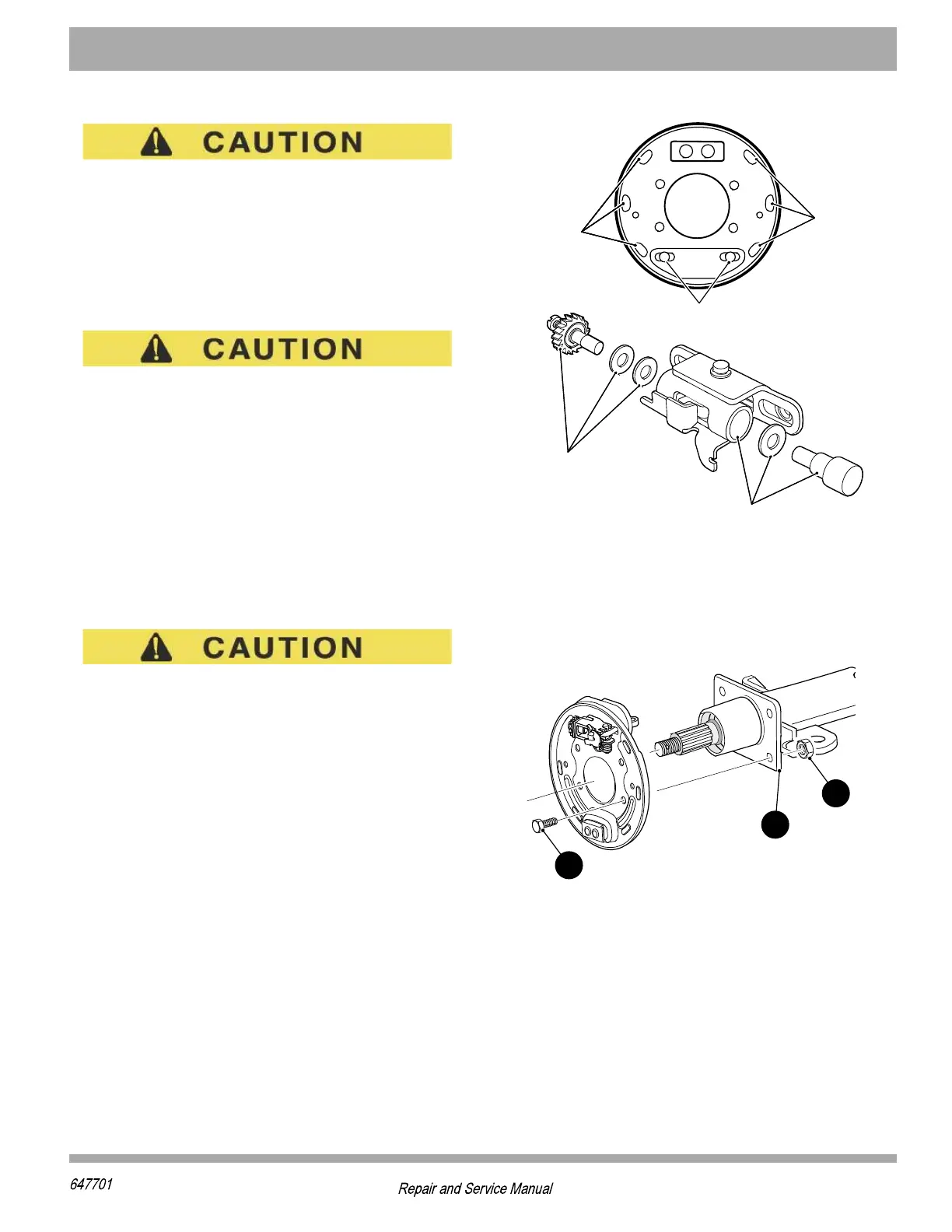

Be sure that the adjusting screw is turned into the

star wheel nut until only 1 - 2 threads are exposed

(Figure 15). If the brake shoes are replaced, replace

the three brake springs and the adjuster

components.

Replace the springs one side at a time, using the other

side as a guide.

Install brake drum as described in Brake Drum Removal

and Installation.

Repeat on other side of vehicle.

Adjust the brake pedal free travel.

Figure 12 Wheel Brake Lubrication Points

Backing Plate/Entire Wheel Brake Assembly

Removal and Installation

Remove the four bolts (1) and lock nuts (2) securing the

wheel brake backing plate to the flange (3) on the axle

tube (Figure 13).

Figure 13 Backing Plate Removal and Installation

Remove the clevis pin securing the brake cable to the

brake lever.

Installation is the reverse of removal. Connect the brake

cable to the wheel brake with the clevis pin installed from

the top down and a new cotter pin. Install the brake

assembly or backing plate to the axle tube flange. Install

new hardware.

0YFVMGEX

(S238

0YFVMGEXI

0YFVMGEXI

&SWWIW

SRIEGL

WMHI

0YFVMGEXI

&SWWIW

SRIEGL

WMHI

0YFVMGEXIWYVJEGIWMRERHEVSYRH

WPSXWERHTPEWXMGWPMHITPEXI

Loading...

Loading...