136

FAULT TESTING

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

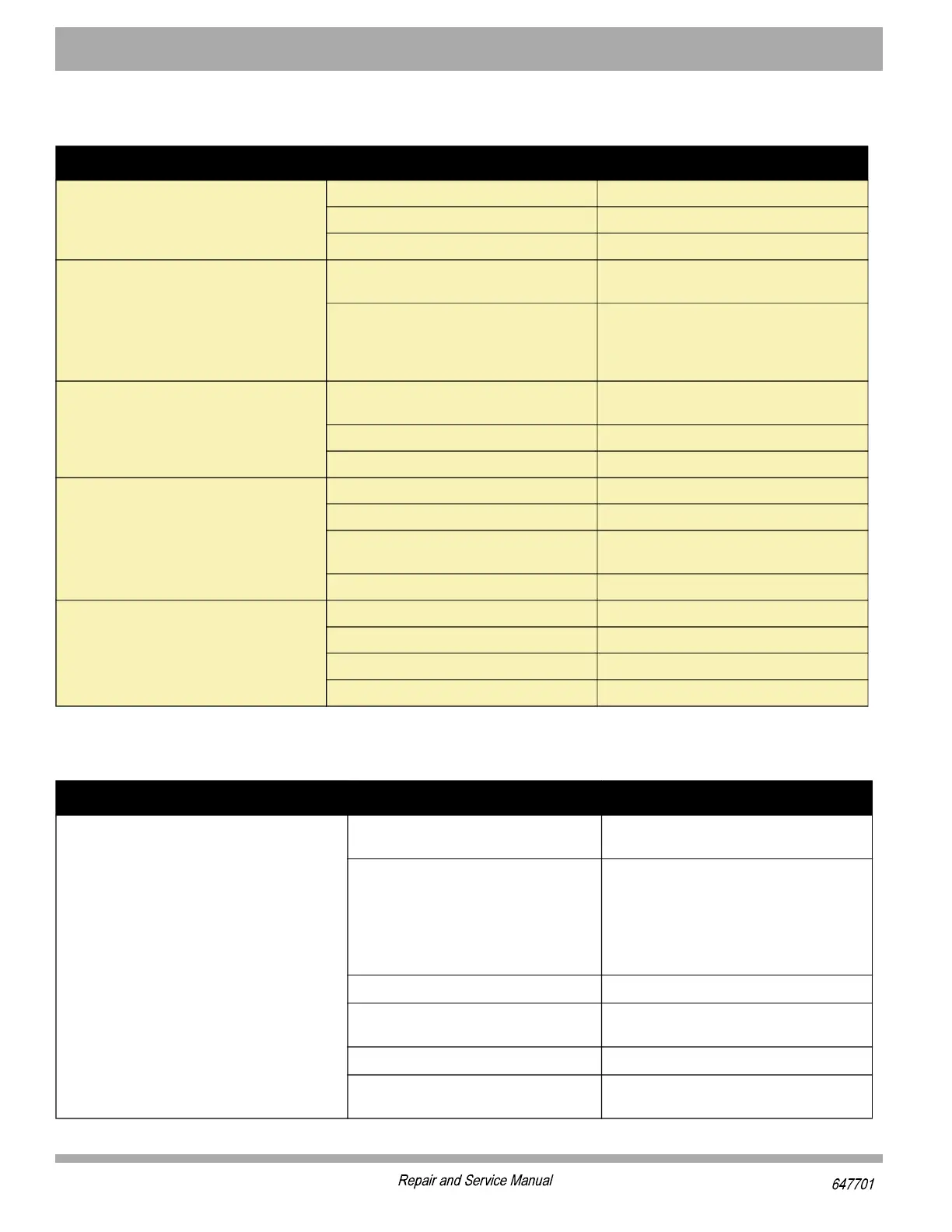

SUSPENSION AND STEERING

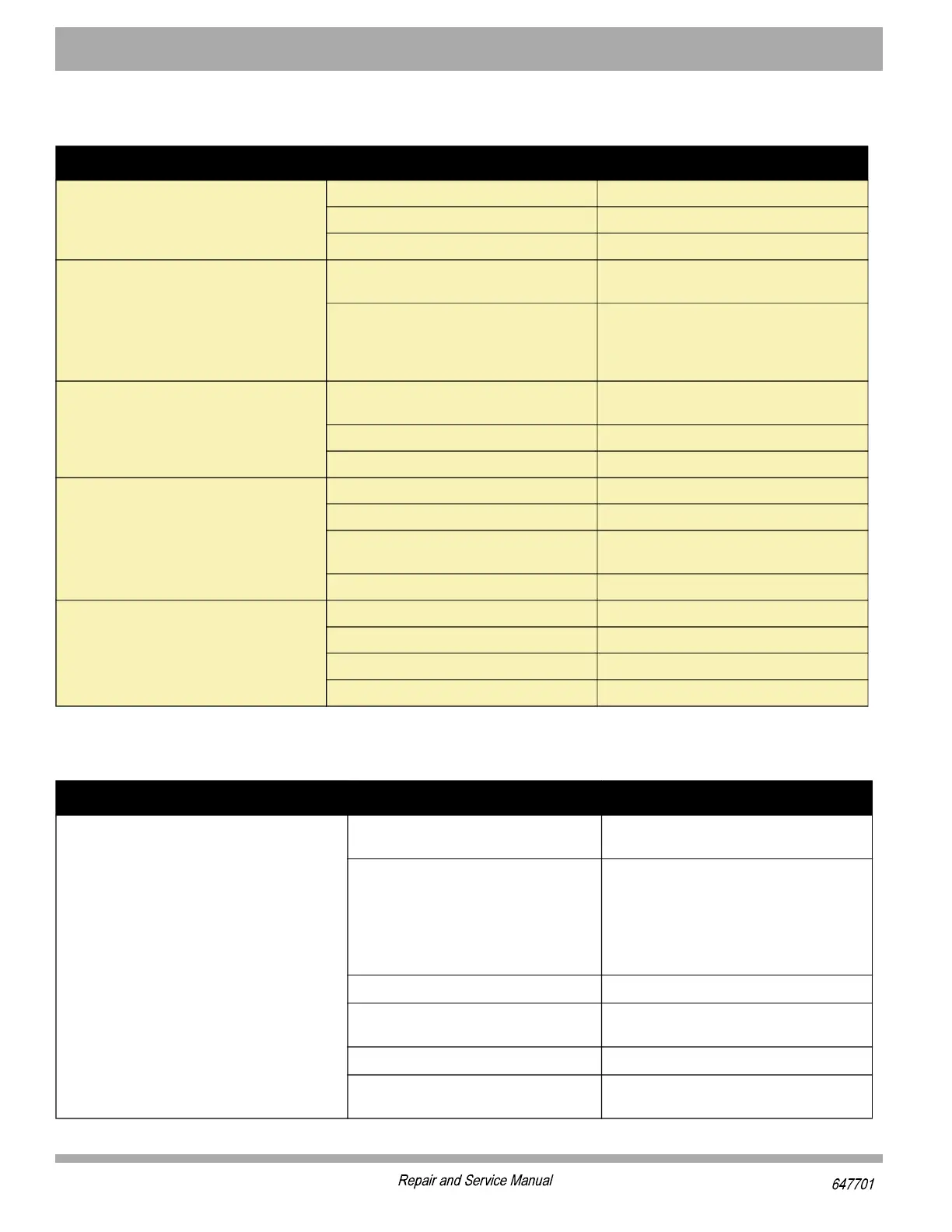

BRAKE SYSTEM

Condition Possible Cause Correction

UNEVEN TIRE WEAR

Incorrect tire pressure Inflate to recommended pressure

Improper alignment (Incorrect toe in) Align front tires

Damaged or worn components Replace

STIFF STEERING

Rusted or contaminated king pin sleeve or

bushings

Replace or clean

Bent rack Remove rack and place on flat surface with

rack teeth up; If a .015" (.381 mm) feeler

gauge will pass under the rack, the rack

must be replaced

PLAY IN STEERING

Steering wheel loose Inspect splines - replace steering wheel if

required; tighten steering wheel nut

Steering components worn Replace

Loose wheel bearings Adjust or replace

VIBRATION

Steering components worn Replace

Loose wheel bearings Adjust or replace

Out of round tires, wheels, or brake

drums

Inspect and replace if out of round

Loose lug nuts Tighten to 50 - 85 ft. lbs. (68 - 115 Nm)

STEERING PULLS TO ONE SIDE

Incorrect tire pressure Inflate to recommended pressure

Dragging wheel brakes Service brake system

Suspension component failure Repair

Alignment incorrect Align

Condition Possible Cause Correction

FAILS BRAKE PERFORMANCE TEST

BY STOPPING IN A LONGER

DISTANCE THAN NORMAL

Wheel brake failure due to severely

worn or damaged components

Replace all severely worn or damaged

components

Brake pedal not returning

Brake not adjusting

Check for binding of brake pedal, if neces-

sary adjust/replace the brake pedal

Check/adjust for brake pedal free travel

Check/replace brake cables

Check/replace brake adjusters

Check/replace pedal pivot

Brake shoes wet Check and make sure brake shoes are dry

Brake cables damaged or sticky Check brake cable and replace if sticky or

damaged

Brake shoes severely worn Replace

Brake shoes glazed Sand shoes with emery cloth provided that

shoes have .06" (1.5 mm) min. material

Loading...

Loading...