FUEL SYSTEM

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

65

to wear or clogging of internal passages with foreign

material. DO NOT bend the float pin during removal.

Refer to “Carburetor fault diagnosis’ on page 134.”.

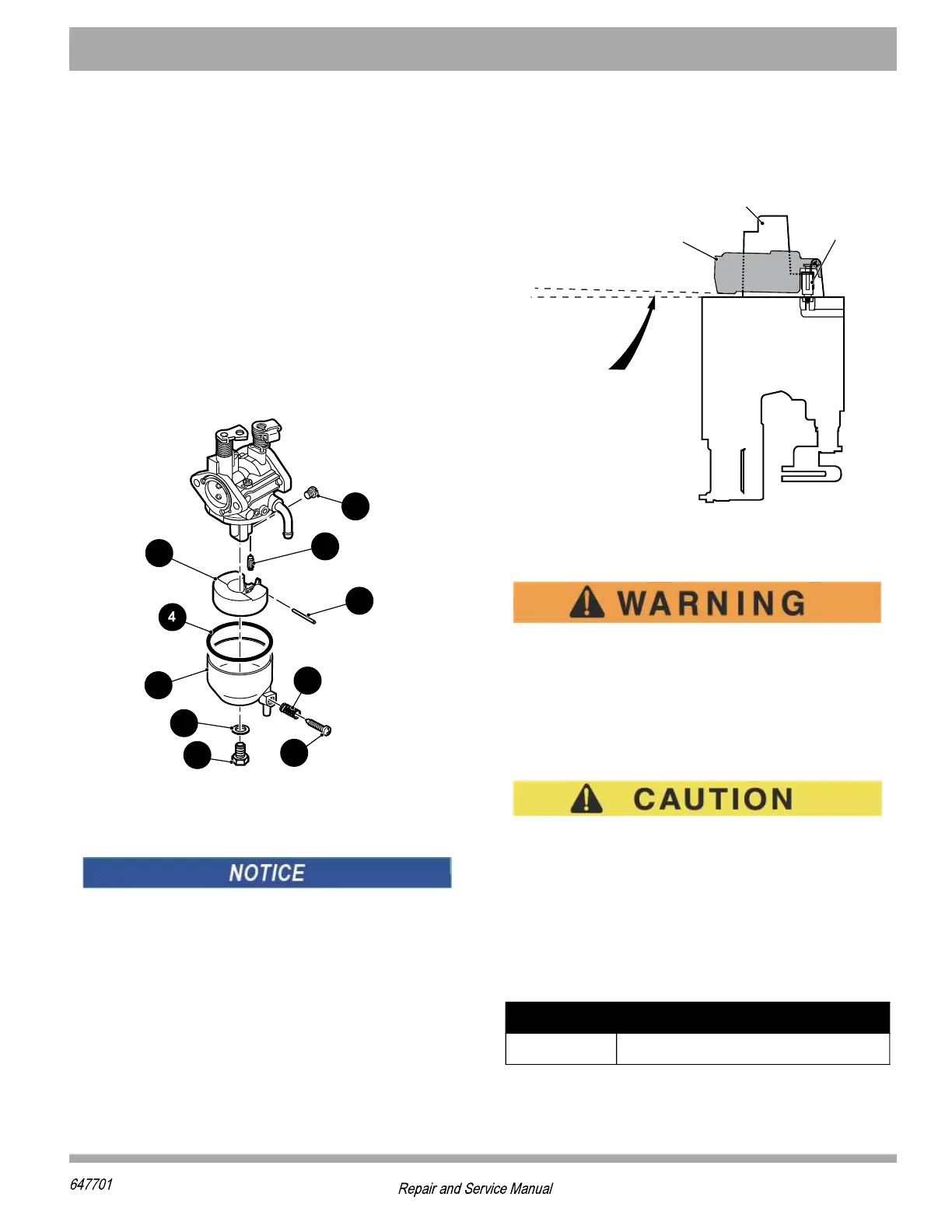

Remove the float bowl (1) by removing the retaining

screw (2) and washer (3) (Figure 9).

Inspect the bowl gasket (4) for nicks or cuts. Carefully

press out the float pin (5), remove the float (6) and the

inlet valve (7). Inspect the inlet valve for wear at its tip.

Remove the main jet (8).

Use solvent to wash all parts and blow through all pas-

sages with compressed air. Replace all gaskets and any

parts which show significant wear or damage. The drain

screw (9) and spring (10) can be used to drain the fuel

from the bowl without removing the bowl.

Figure 9 Carburetor Disassembly

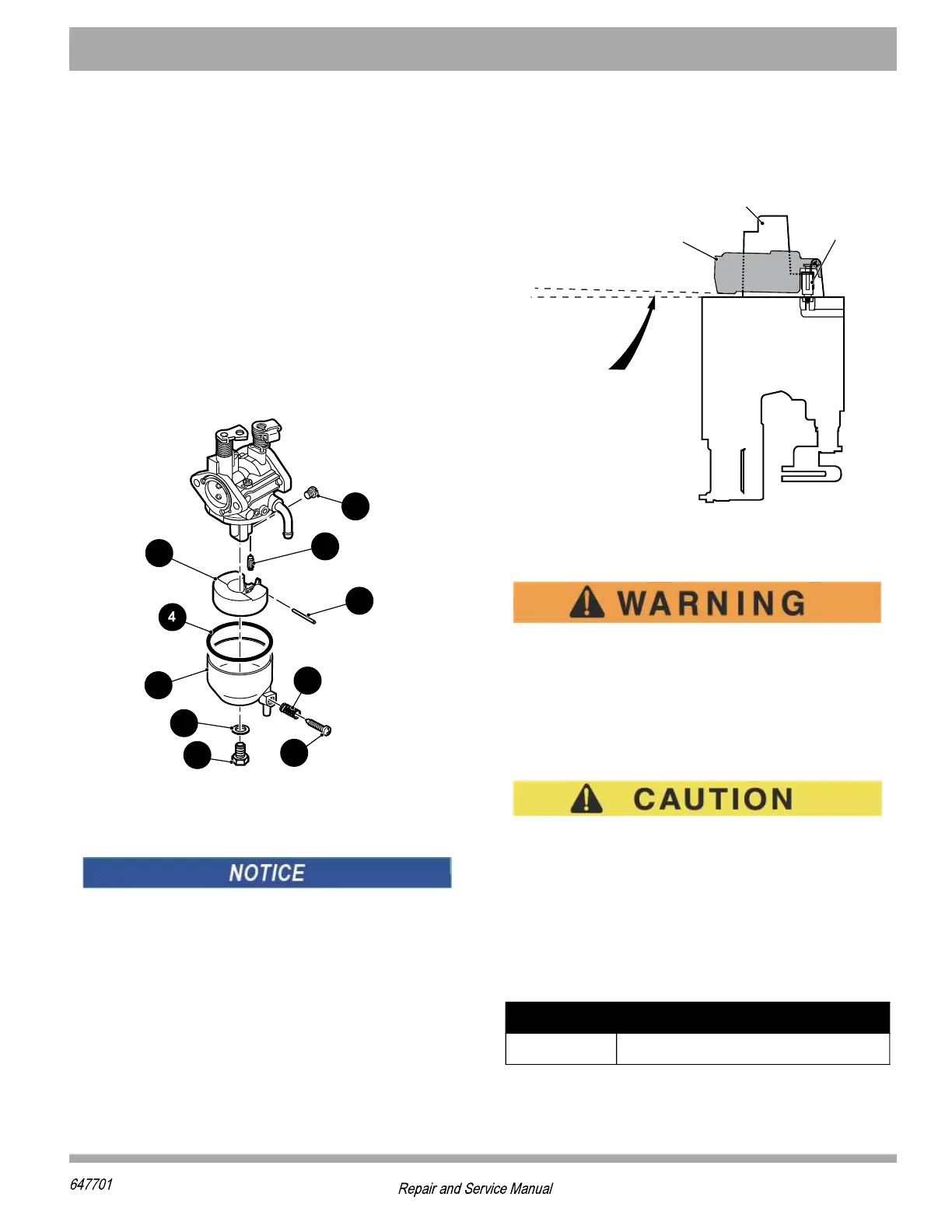

Float Level Alignment

The float level cannot be adjusted but should be

inspected for proper alignment.

Turn the carburetor upside down. Remove the bowl. With

the carburetor inverted, the B side top edge of a properly

adjusted float will be slightly above parallel to the bowl

gasket surface and both sides of the float will be level with

each other (Figure 10). If the sides of the float are not par-

allel or if the B side of the float is not slightly above paral-

lel with the bowl gasket surface then the float should be

replaced. Reinstall the bowl, washer and the screw.

Check for fuel leaks.

Check for free movement of the choke shaft before

installing the carburetor. Lubricate the bushings with WD-

40

®

oil or equivalent.

Figure 10 Float Adjustment

Carburetor Installation

To decrease the risk of possible injury from

explosion or fire, check for clogged or kinked

hoses. Clogged or kinked carburetor hoses are

not only detrimental to the proper operation

and performance of the vehicle, but can also

be a safety hazard in the case of fuel leaking

on a hot engine.

Do not let the carburetor vent hose become clogged

or kinked. Engine heat will cause the fuel in the car-

buretor bowl to expand and may result in fuel being

expelled from the carburetor if unable to vent

through the vent tube.

Replace the carburetor in reverse order of removal. Use a

new gasket to ensure sealing of carburetor. Tighten hard-

ware to torque value specified below (Figure 9).

Item Torque Specification

Hardware

50 - 70 in. lbs. (6 - 8 Nm)

*PSEXWLSYPHFIEPMKRIHWS

XLEXXSTMWTEVEPPIPSV

qWPMKLXP]EFSZIrTEVEPPIP

[MXLKEWOIXWYVJEGI

*PSEX

*PSEX

:EPZI

'EVFYVIXSV

&SH]

*PSEX'LEQFIV7XIQ

Loading...

Loading...