52

ENGINE

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

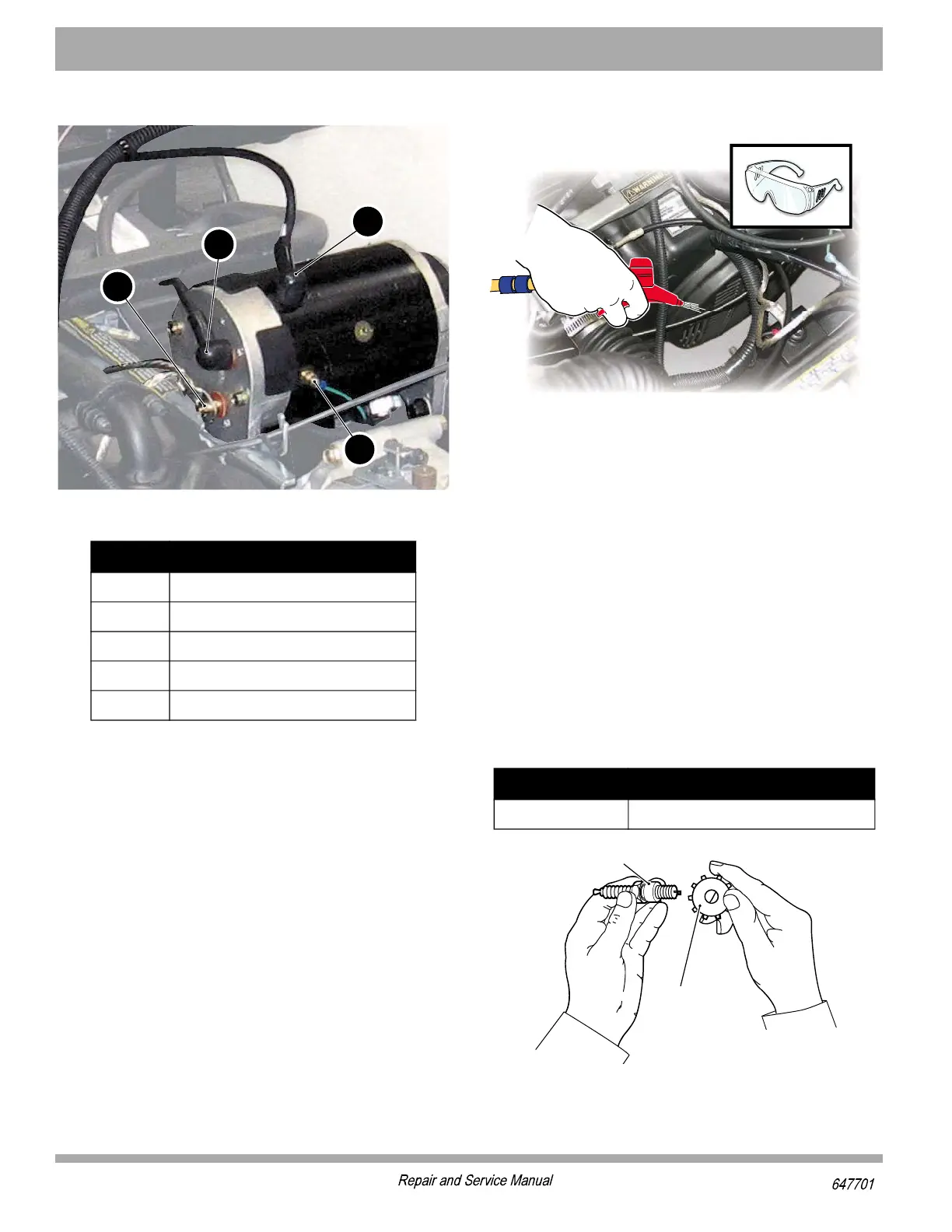

Figure 13 Starter/Generator Wire Connections

Figure 14 Starter/Generator Wiring

COOLING SYSTEM CLEANING

At least once a year, or more often under adverse condi-

tions, the cooling system should be cleaned. Cleaning will

assure an adequate supply of air to the cooling fins. Com-

pressed air may be used for routine cooling system main-

tenance (Figure 15).

Operation in wet or damp weather or over freshly cut

grass may result in a variety of debris accumulating and

adhering to the internal shroud and fins of the cooling sys-

tem.

Figure 15 Cleaning Cooling System with Air

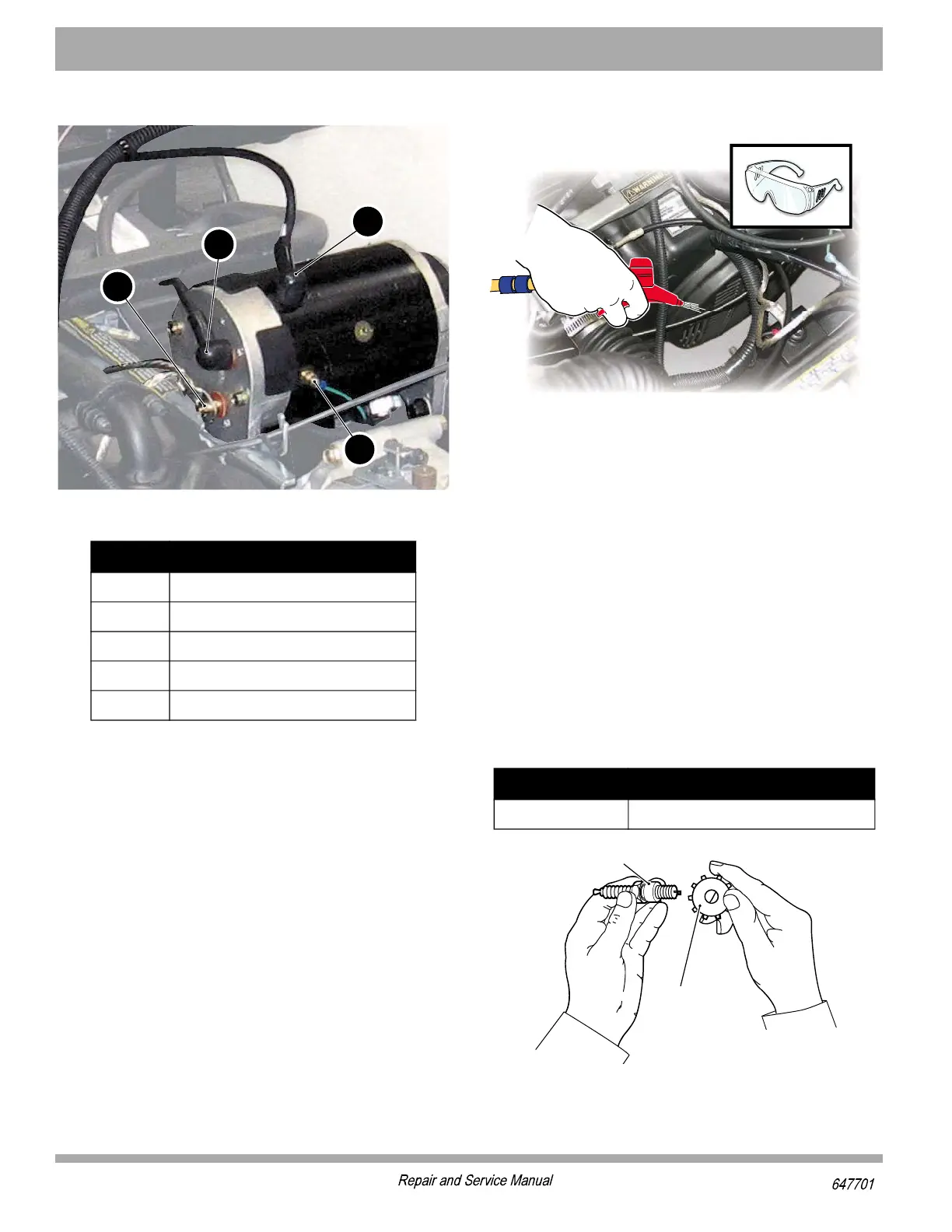

SPARK PLUG

Tool List Qty.

Spark Plug Socket,13/16” ............................................1

Feeler Gauge, Wire Type.............................................1

Ratchet ........................................................................1

Extension .....................................................................1

Torque Wrench, ft. lbs. ................................................1

Anti-Seize Compound..................................................1

This engine uses Spark Plug NGK BPR2ES with a gap of

.028" - .031" (.70 - .80 mm). Using a 13/16” spark plug

socket or wrench, remove the spark plug at 125 hours or

semi-annually and clean and re-gap. The spark plug

should be properly gapped and replaced in the cylinder

head. Tighten the spark plug to the torque value specified

below (Figure 16).

Figure 16 Gapping the Spark Plug

From To

A1 Ground

A2 Terminal F1 on Starter/Generator

F1 Terminal A2 on Starter/Generator

F2 Terminal A on Solenoid

DF Green wire to Voltage Regulator

%

%

*

(*

Item Torque Specification

Spark Plug 16 ft. lbs. (22 Nm)

QQ

rr

+ET

7TEVO4PYK

Loading...

Loading...