2AV/X

2-1-13

2-1

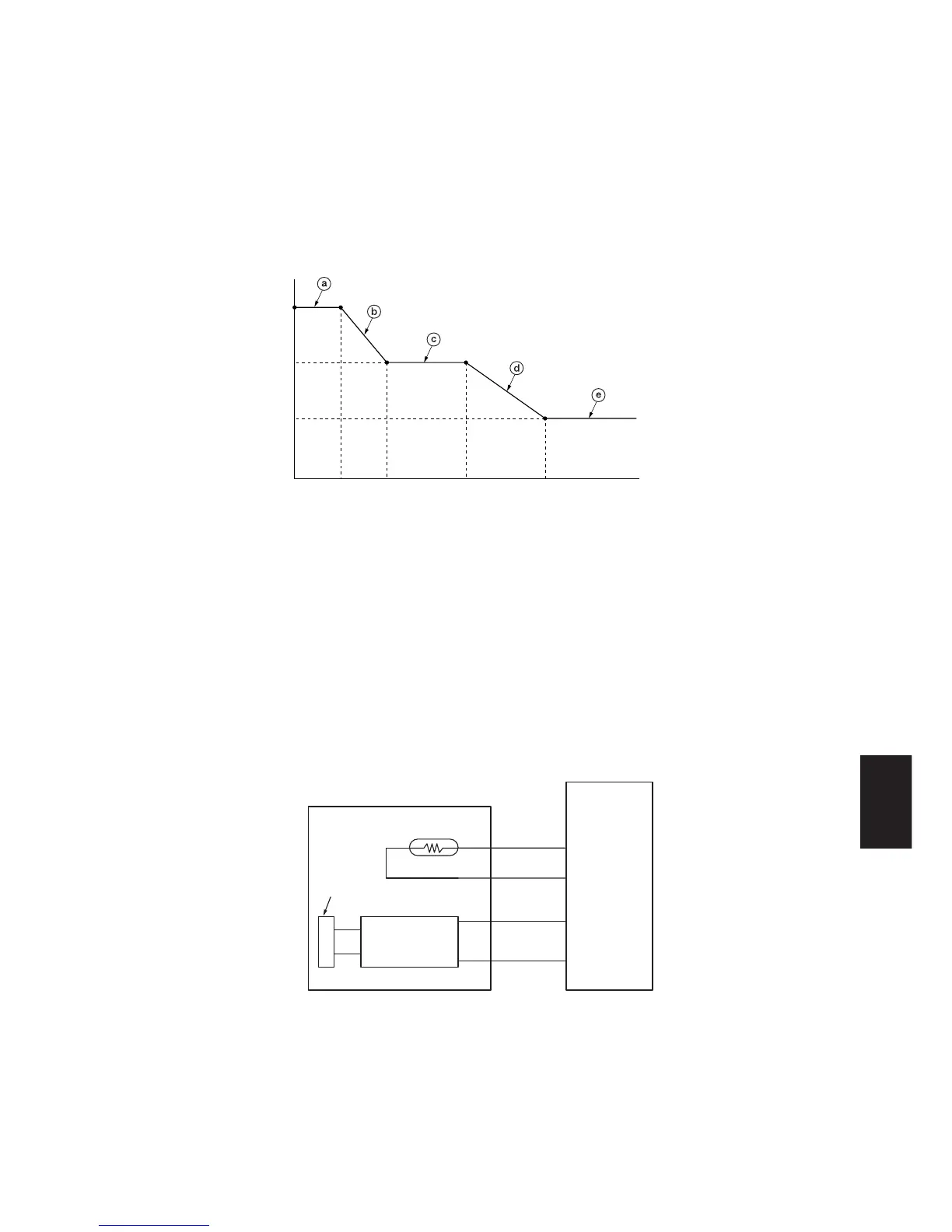

(4) Correcting the toner sensor control voltage

The toner sensor control voltage is corrected based on the absolute humidity and the total drive motor time so that the

toner density is kept constant regardless of the changes in humidity and the total drive motor time.

Toner sensor control voltage after correction = A + B + C

A: Toner sensor control voltage before correction (value set by maintenance item U131)

B: Correction data based on the absolute humidity

C: Correction data based on the total drive motor time

• Correction based on the absolute humidity

+15

Correction data

1.5 4.0 10.0 19.0

Absolute humidity (g/m

3

)

0

0

-15

Figure 2-1-17 Correction based on the absolute humidity

a: When the absolute humidity is between 0 and 1.5 g/m

3

, a constant value of +15 is added to the toner sensor control

voltage.

b: When the absolute humidity is between 1.5 and 4.0 g/m

3

, the correction data is reduced according to the rise in

absolute humidity.

c: When the absolute humidity is between 4.0 and 10.0 g/m

3

, the correction data becomes 0.

d: When the absolute humidity is between 10.0 and 18.0 g/m

3

, the correction data is decreased according to the rise in

absolute humidity, reducing the toner sensor control voltage.

e: When the absolute humidity exceeds 18.0 g/m

3

, the correction data becomes a constant value of –15, decreasing the

toner sensor control voltage.

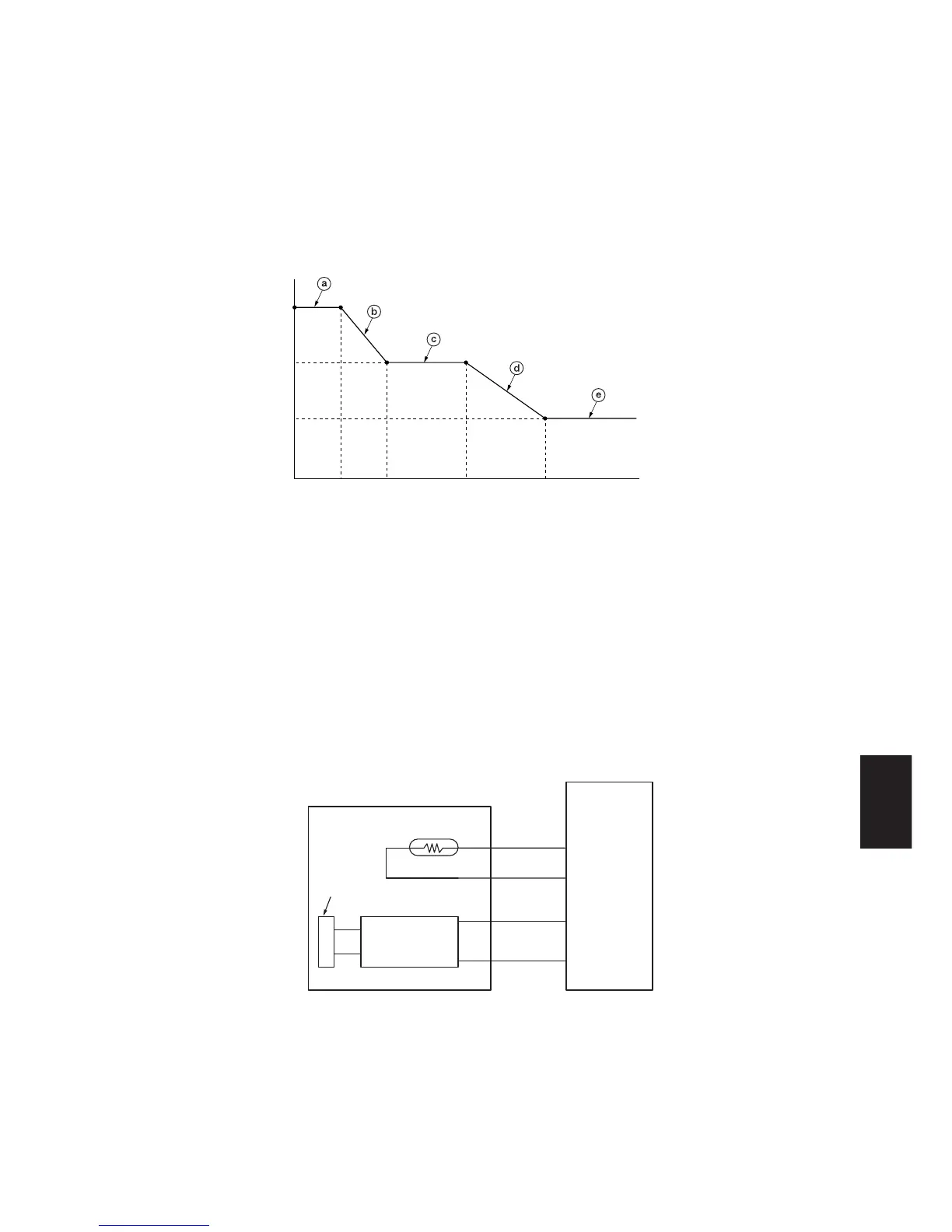

Computing the absolute humidity

The humidity sensor (HUMSENS) converts the relative humidity detected by the humidity sensing element into a voltage

and sends it to the main PCB (MPCB). The main PCB (MPCB) computes the absolute humidity based on this HUMSENS

signal and the temperature (ETTH signal) detected by the external temperature thermistor (ETTH).

MPCB

HUMSENS

2 HUMSENS

1 DC5V

CN7-1

CN7-2

CN7-3

CN7-4

4

3

ETTH

ETTH

GND

Humidity

sensing

element

Figure 2-1-18 Absolute humidity computation block diagram

Loading...

Loading...