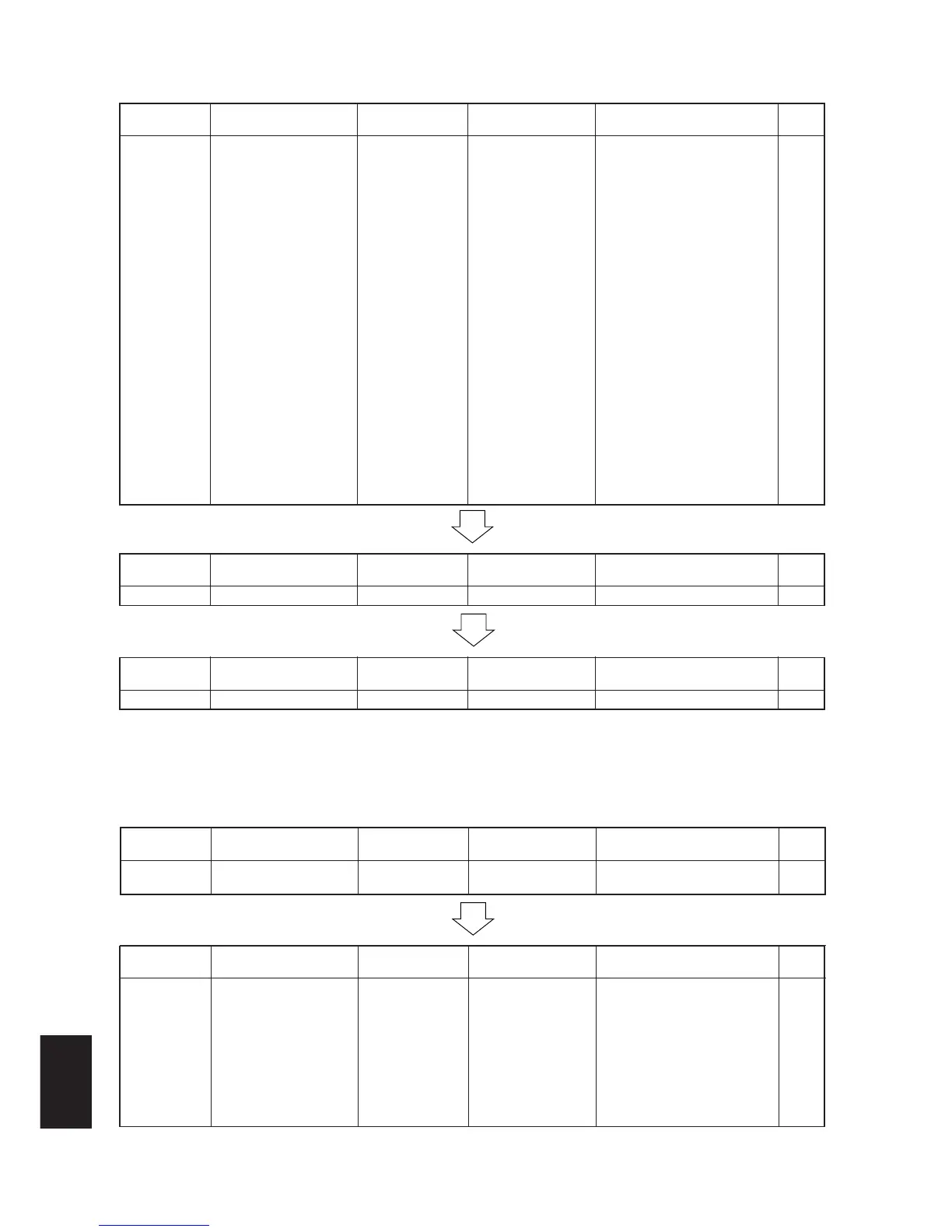

2AV/X

2-4-14

2-4

Maintenance

Section

part/location

Method Maintenance cycle Points and cautions Page

Fixing/Eject Heat roller Clean or replace Clean after 100,000 Clean with alcohol. 1-6-51

section counts; check and

replace after 200,000

counts

Press roller Clean or replace Clean after 100,000 Clean with alcohol. 1-6-53

counts; check and

replace after 200,000

counts

Bushing Check and replace After 200,000 counts Check the installation position 1-6-51

and noise.

Bearing Check and replace After 200,000 counts Check the installation position 1-6-53

and noise.

Fixing unit themistor Check and clean After 200,000 counts Clean with alcohol and check for 1-6-49

peeling of the film.

Heat roller separation claw Clean or replace After 200,000 counts Clean with alcohol. 1-6-49

Fixing heater Check and replace After 200,000 counts Check if the lamp is dark or not. 1-6-50

Gear Check and replace Every service Check for chips in the gear. 1-6-51

Eject roller Clean Every service Clean with alcohol or a dry cloth.

Eject pulley Clean Every service Clean with alcohol or a dry cloth.

Eject roller Clean and grease Every service Check noise. If noise is heard,

apply grease TMP1-200G to the

contacting surfaces of the eject

roller and bushing.

Maintenance

Section

part/location

Method Maintenance cycle Points and cautions Page

Covers Covers Clean Every service Clean with alcohol or a dry cloth.

Maintenance

Section

part/location

Method Maintenance cycle Points and cautions Page

Other Image quality Check and adjust Every service

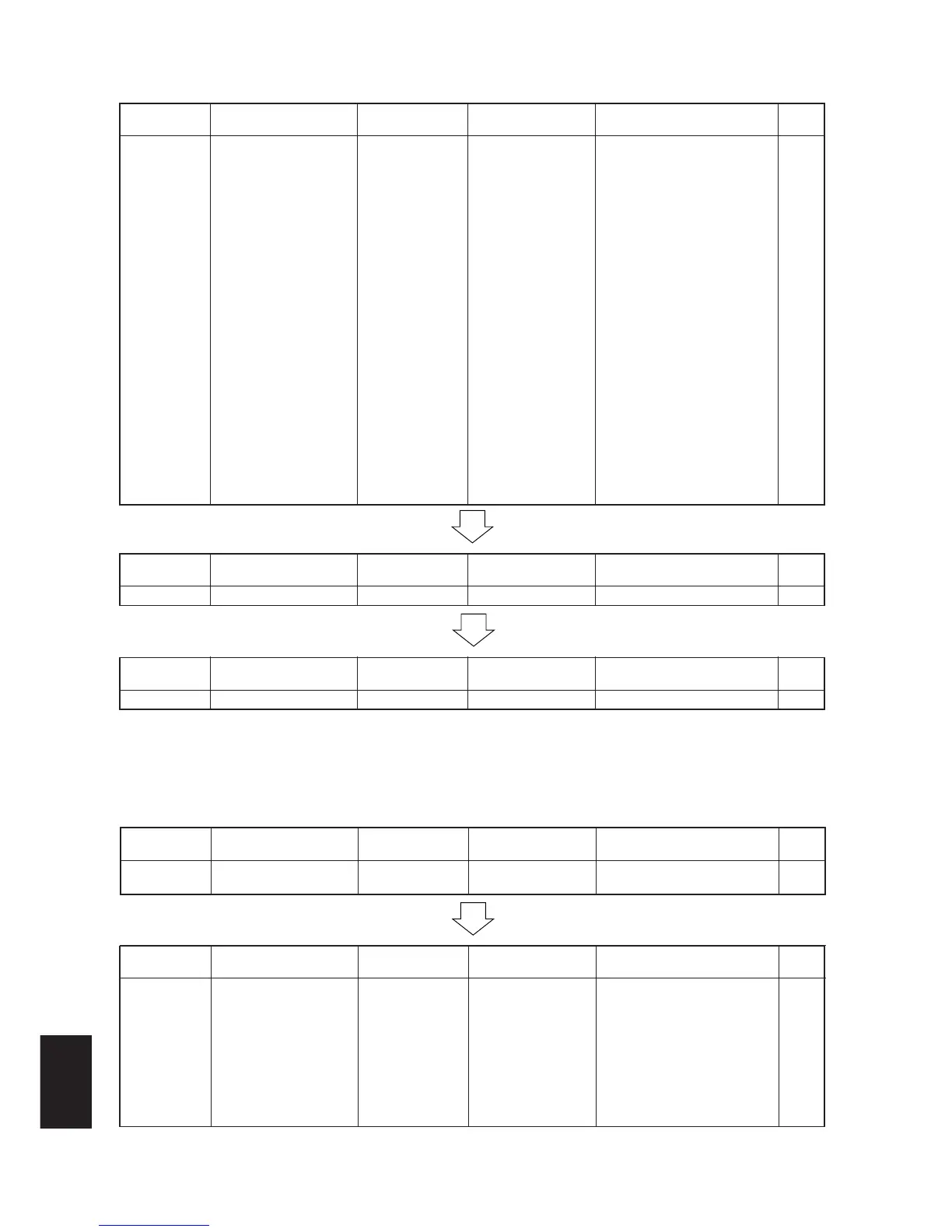

Maintenance

Section

part/location

Method Maintenance cycle Points and cautions Page

Test copy and Perform at the maximum Test copy Every service

test print copy size

Maintenance

Section

part/location

Method Maintenance cycle Points and cautions Page

Paper feed Paper feed pulleys Clean Every service Clean with alcohol or a dry cloth.

section

Check Every service Check the leading edge

registration and paper feed

conditions in the registration

section, bypass and paper feed

section.

Paper feed roller Clean Every service Clean with alcohol or a dry cloth.

Bushings Check Every service Check noise. If noise is heard,

apply grease TMP-200G.

• Optional drawer

Loading...

Loading...