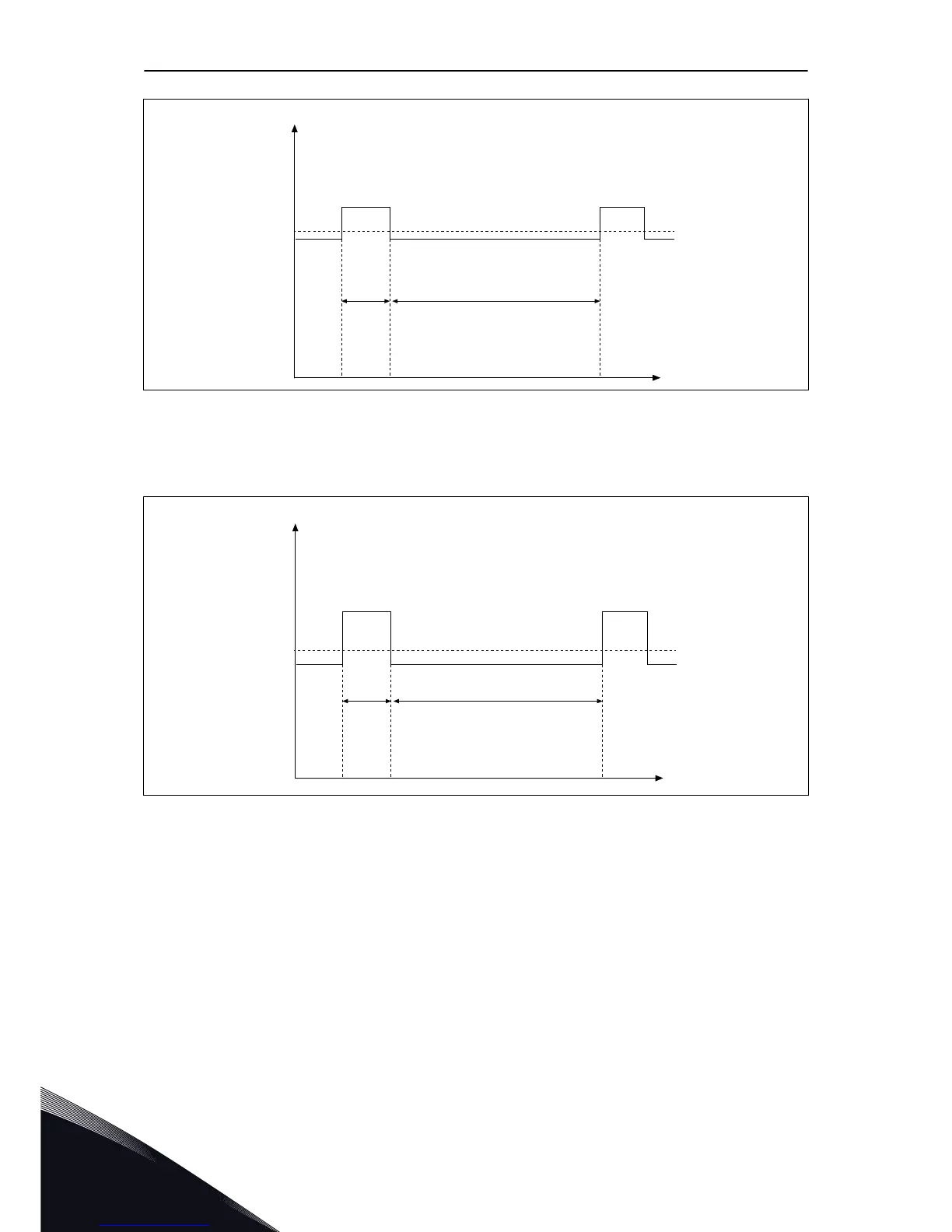

Fig. 33: Low overload

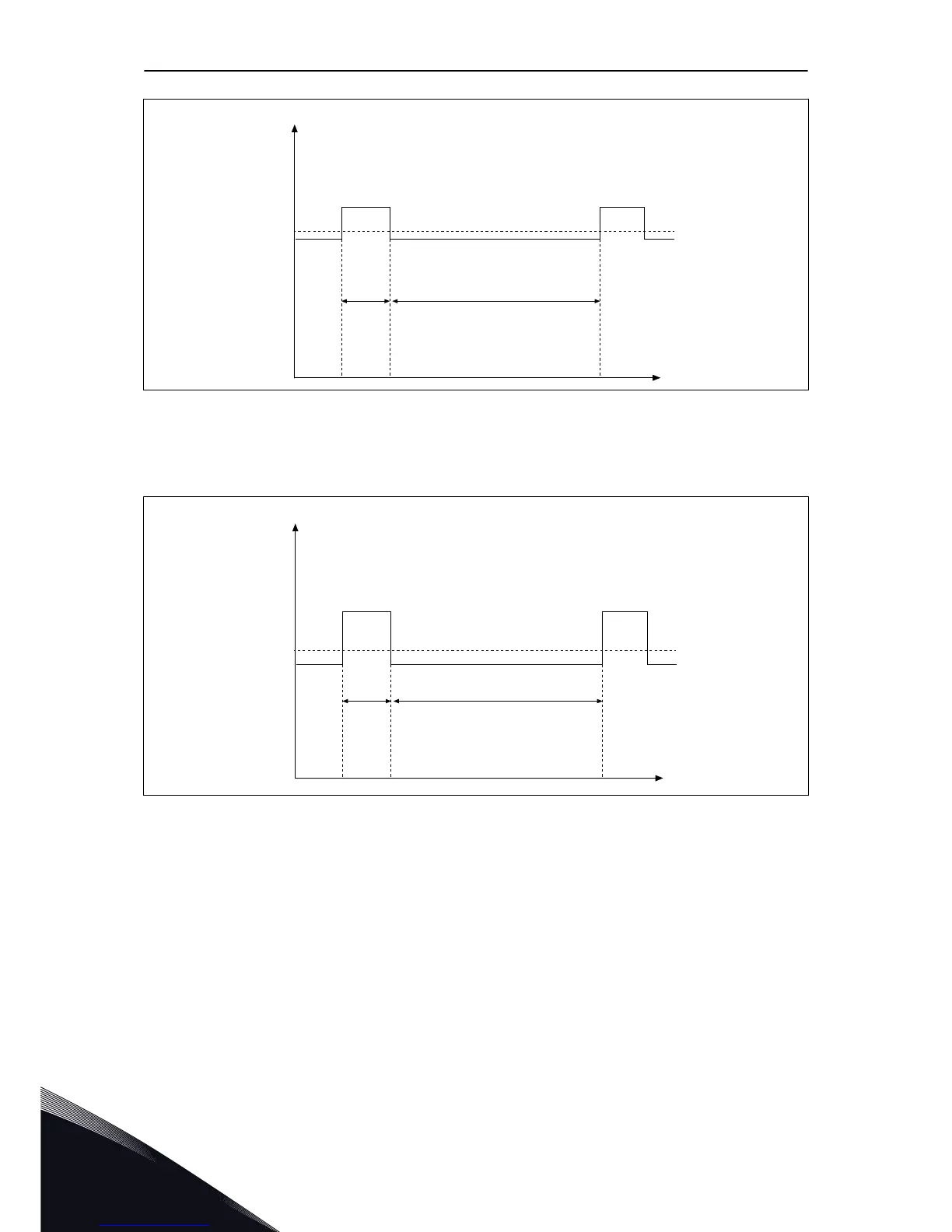

The high overload means that if 150% of the continuous current (I

H

) is required for 1 minute

every 10 minutes, the remaining 9 minutes must be approximately 92% of I

H

or less. This is to

make sure that the output current is not more than I

H

during the duty cycle.

Fig. 34: High overload

For more information, refer to the standard IEC61800-2 (IEC:1998).

9.1.5 BRAKE RESISTOR RATINGS

Make sure that the resistance is higher than the set minimum resistance. The power

handling capacity must be sufficient for the application.

VACON · 106 TECHNICAL DATA, VACON® 100 INDUSTRIAL

9

LOCAL CONTACTS: HTTP://DRIVES.DANFOSS.COM/DANFOSS-DRIVES/LOCAL-CONTACTS/

Loading...

Loading...