Videojet DataFlex 6530 Operator Manual - Rev AA 8-7

Troubleshooting

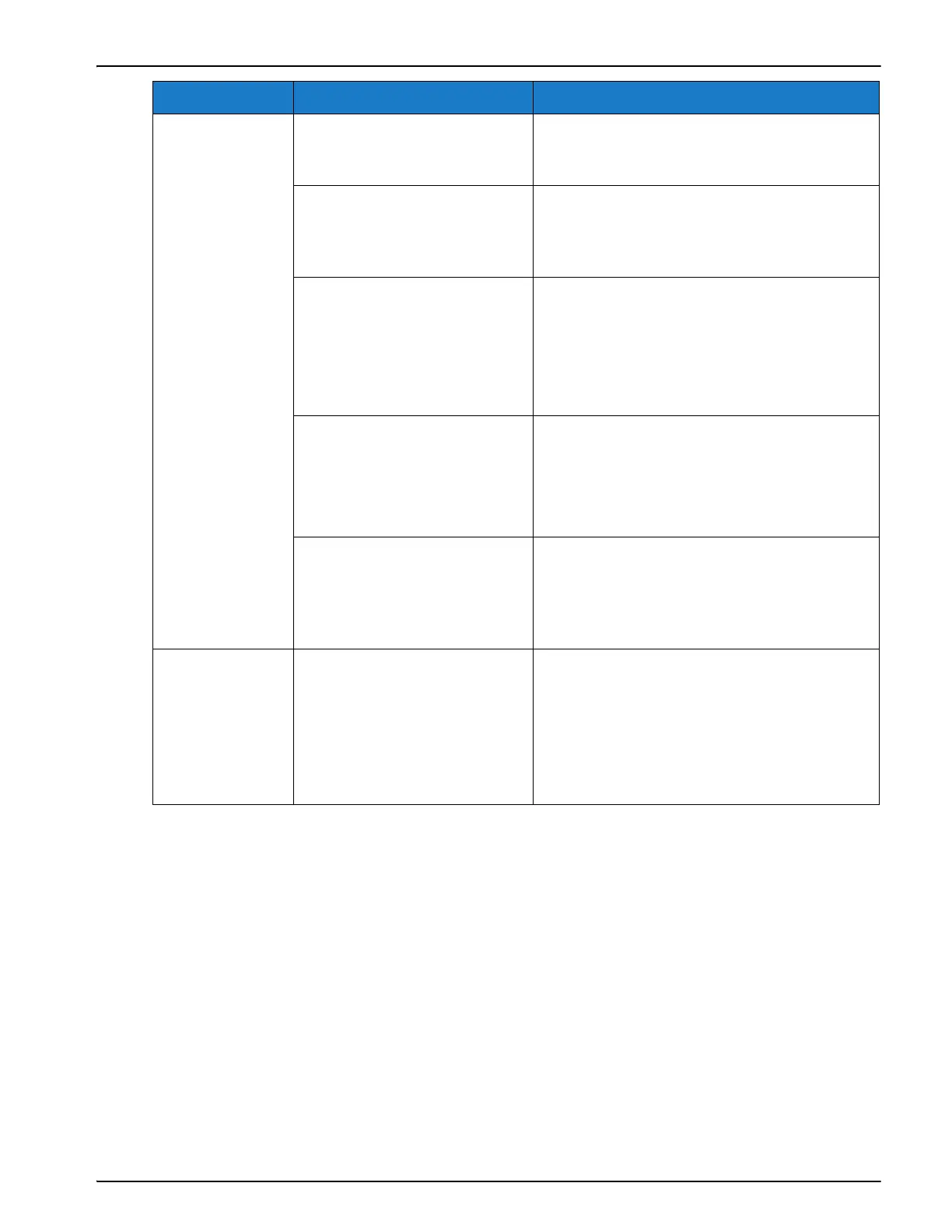

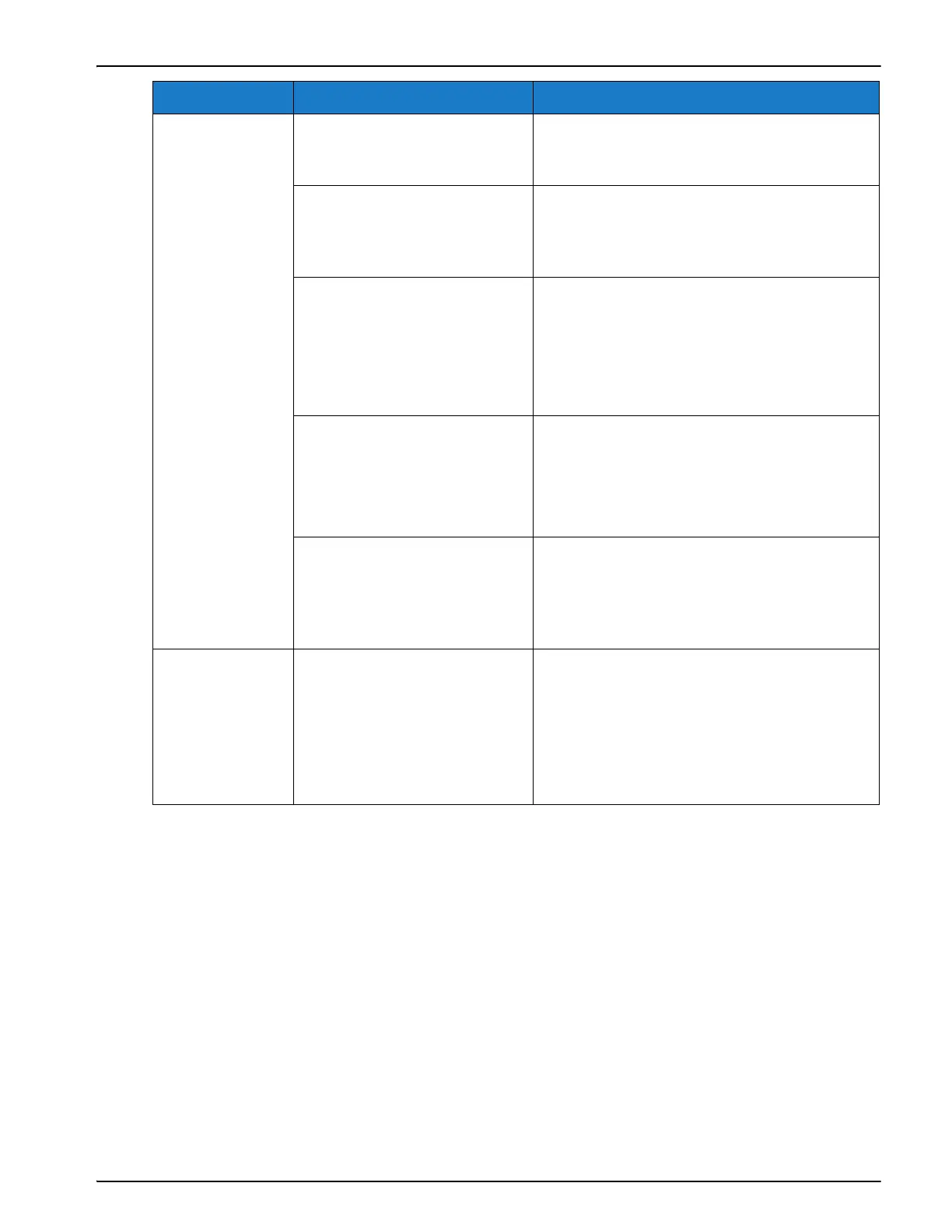

Substrate Speed

Detection

Continuous Mode Only:

Worn or missing encoder

O-ring

Check condition of encoder O-ring.

Replace if necessary.

Continuous Mode Only:

Encoder O-ring slipping or

not making good contact

with peel roller

Ensure encoder O-ring making good

contact with peel roller.

Intermittent Mode Only:

Substrate is moving while

printer is printing

Navigate to Tools > Setup > Printhead.

If substrate is not settled before printer

begins to print, adjust Print Delay.

If substrate begins to advance before

printer finishes printing, increase Print

Speed.

Ribbon is 'stuck' to the

substrate and is being

pulled/tugged

Ensure substrate is not 'tacky'.

Try lowering Print Darkness and/or Print

Force settings if needed.

Intermittent Mode Only:

Try increasing Print Speed.

Ribbon going slack due to

damaged cassette

Inspect cassette for damaged components

such as baseplate, cassette rollers, mandrel,

mandrel pins, and friction cones. Ensure no

components are bent or misaligned.

Replace components as necessary.

Print Cycle

Error

Continuous Mode Only:

Current printer settings not

optimized for the application

Navigate to Tools > Diagnostics > Printhead

> Encoder Profiles and Capture Encoder

Profile to determine max substrate speed.

Then using CLARiTY Configuration

Manager, lower the Continuous Maximum

Print Speed setting to be ~50-100mm/sec

greater than max substrate speed.

Error Message Possible Causes

Remedies

Table 8-1: Printer Faults (continued)

Loading...

Loading...