Chapter 4 Deployment of the CPU 21x-2BT10 with TCP/IP Manual VIPA CPU 21x

4-2 HB103E - Rev. 05/45

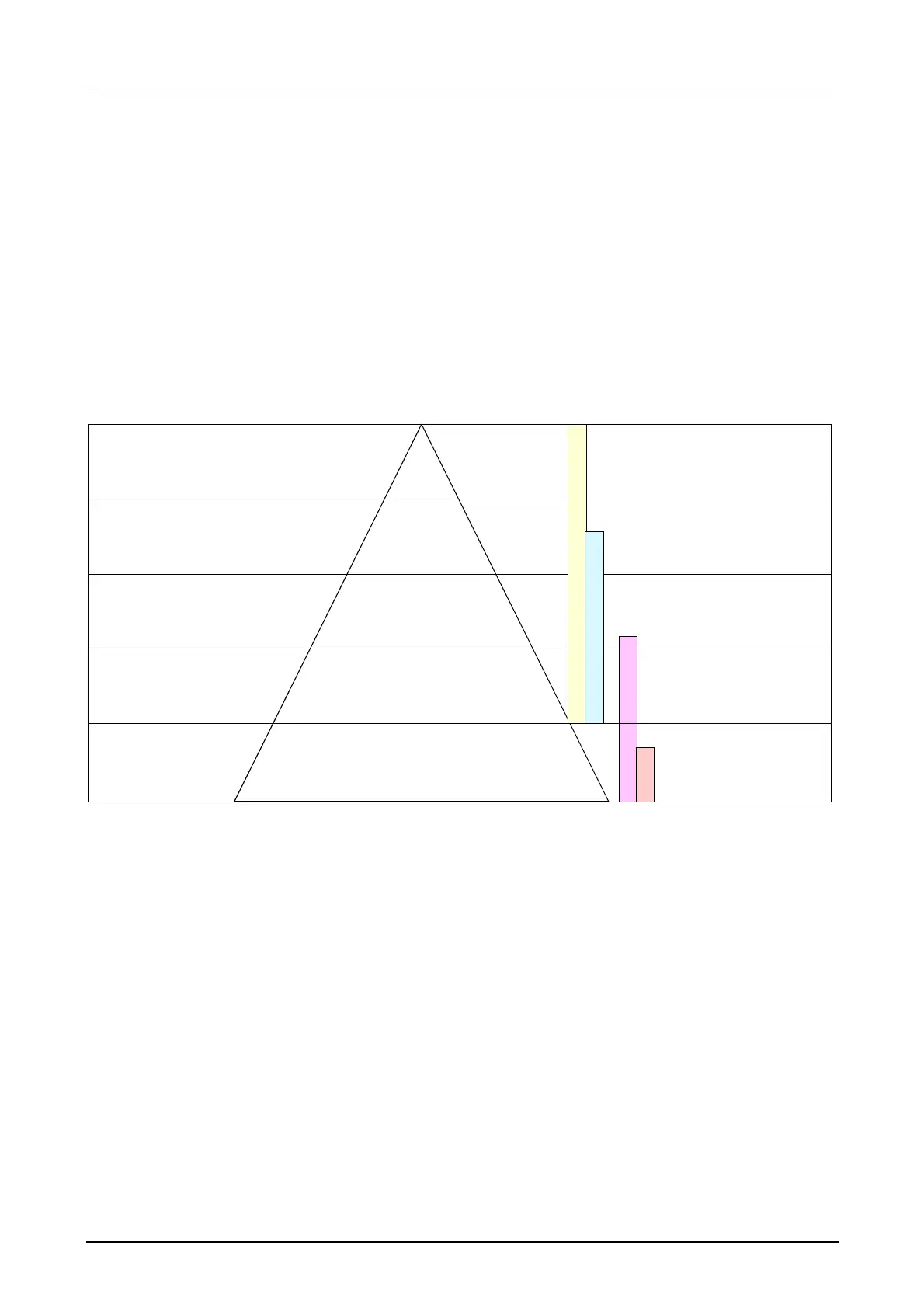

Industrial Ethernet in automation

The flow of information in a company presents a vast spectrum of

requirements that must be met by the communication systems. Depending

on the area of business the bus system or LAN must support a different

number of users, different volumes of data must be transferred and the

intervals between transfers may vary, etc.

It is for this reason that different bus systems are employed depending on

the respective task. These may be subdivided into different classes. The

following model depicts the relationship between the different bus systems

and the hierarchical structures of a company:

Operational layer

Management layer

System layer

Prozess layer

Sensor / actuator

layer

Field bus

Sensor / actuator

Bus

H1

Industrial

Ethernet

Plant

computer

PPS CAD

Plant-oriented

control computer

manufacturing, stock,

production data

PPS CAD

Machine and control

computer

Peripheral systems. machines, CNC, NC,

controllers (PLC), measuring systems

Peripheral components

sensor, actuator, regulator, multiplexer, operating consoles

Industrial Ethernet is an electrical net based on shielded twisted pair

cabeling or optical net based on optical fibre.

Industrial Ethernet is defined by the international standard IEEE 802.3. The

net access of Industrial Ethernet corresponds to IEEE 802.3 - CSMA/CD

(Carrier Sense Multiple Access/Collision Detection) scheme: every station

“listens” on the bus cable and receives communication messages that are

addressed to it.

Stations will only initiate a transmission when the line is unoccupied. In the

event that two participants should start transmitting simultaneously, they

will detect this and stop transmitting to restart after a random delay time

has expired.

Using switches there is the possibility for communication without collisions.

Overview

Industrial Ethernet

Loading...

Loading...