Maintenance—Schedule

T7M7G6M,00003B5-19-14JUL20-1/1

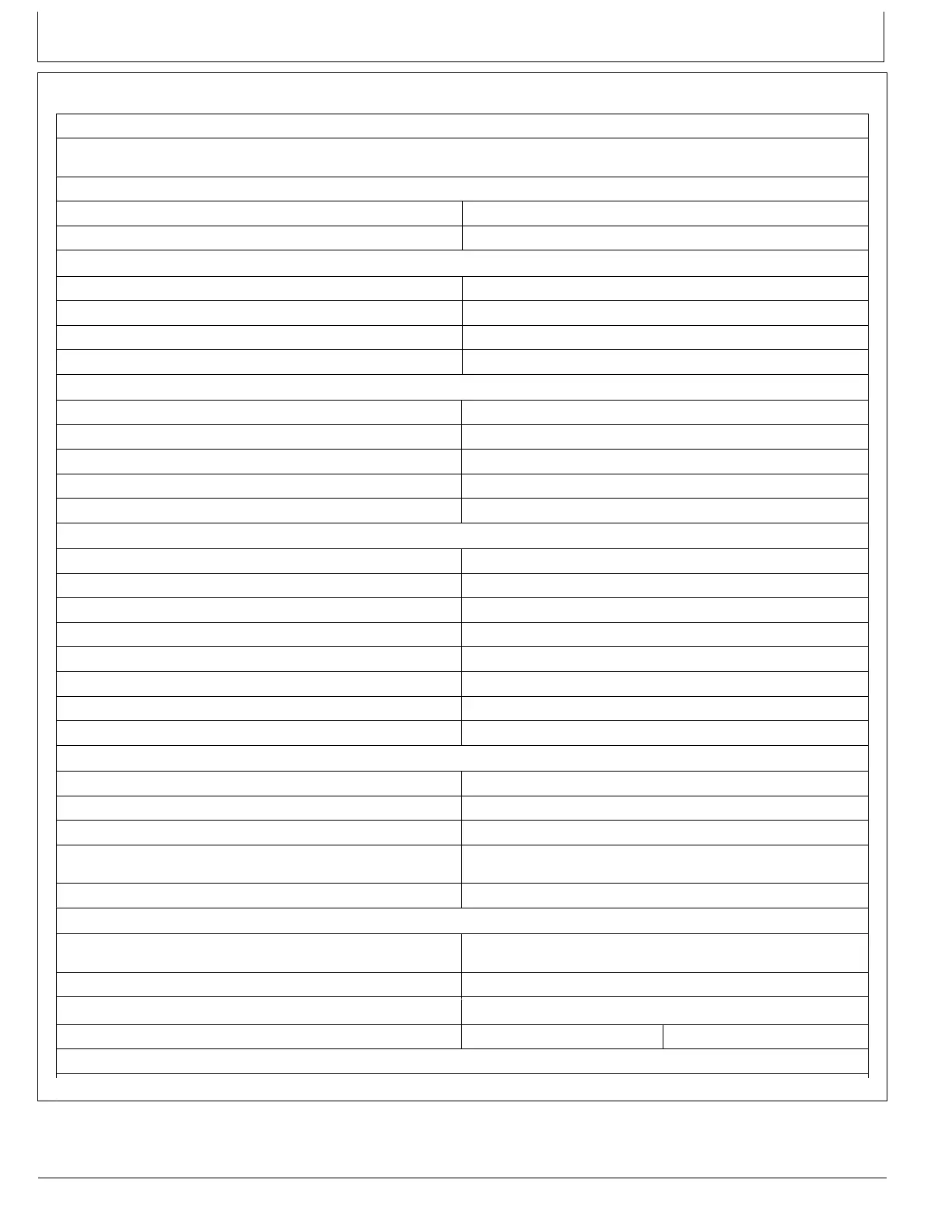

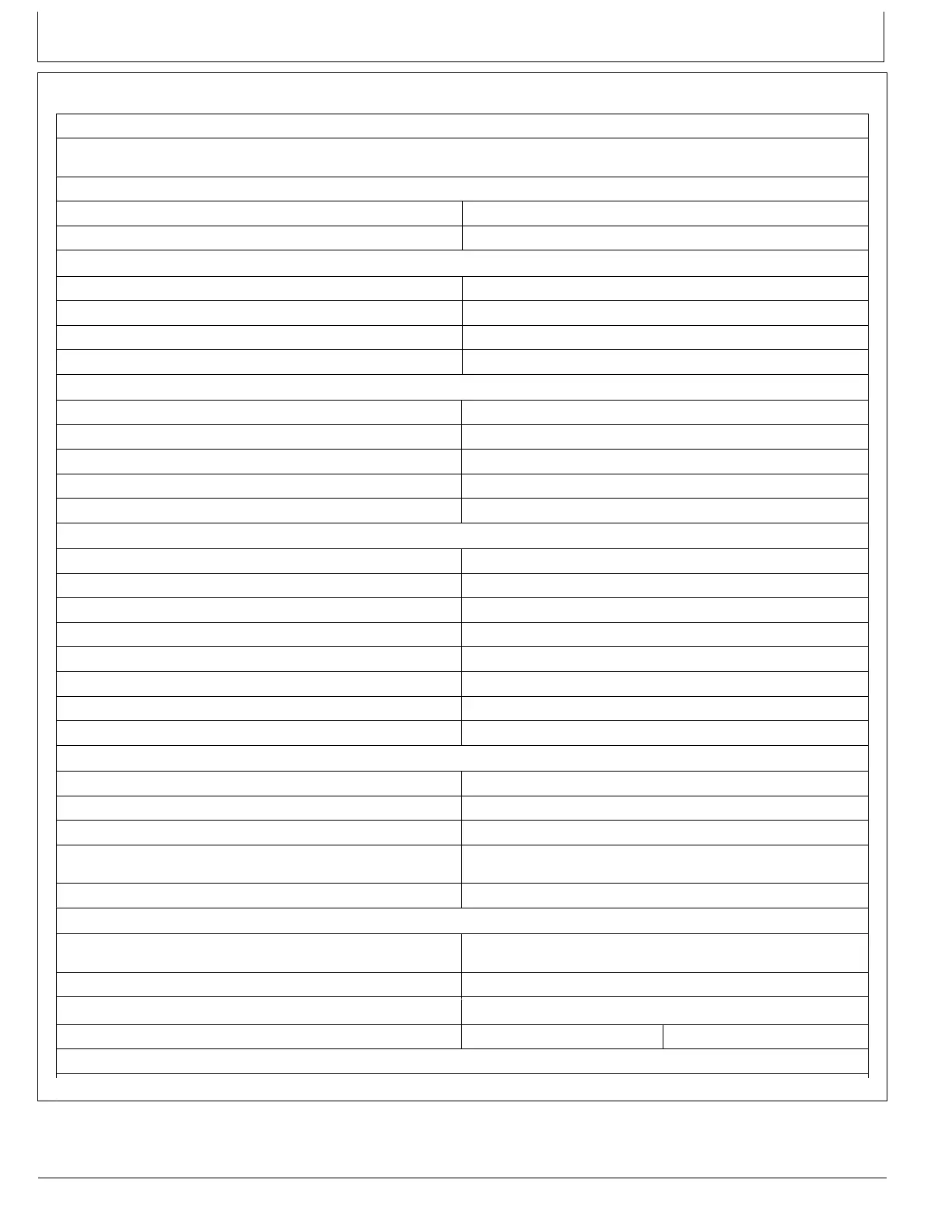

PeriodicMaintenanceRecord

SERVICEINTERVALS

Serviceintervalsareshownonthischart.Alsoperformserviceonitemsatmultiplesoftheoriginalrequirement.Forexample,at2000hoursalso

servicethoseitems(ifapplicable)listedunder1000hours,200–250hours,50hours,and8hoursordaily.

AsRequired

□Inspecttopsawandmainsawchaincondition

□Cleandebarkingfeedrollersandpaintmarkingequipment

□Inspectchainshotguard

□Cleandebrisfromarm,sawandmeasureequipment

Every8HoursorDaily

□Inspecttopsawandmainsawchaincondition□Inspectandcleanmeasuringequipmentandsensors

□Lubricateallgreasettings(Every4hoursifworkingwithhardwood)

□Filllubricationreservoir

□Checkcontrolvalve,motors,cylinders,andhosesforleaksorwear□Checkhydraulicoillevel

□Inspectchainshotguard

Every50HoursorWeekly

□Completethe8hourordailyschedule□Checkupperdelimbknifepivotpincapscrewtorque

□Inspectframeandarmsforcracksorexcessivewear□Checkfeedrollerconditionandfeedrollerhubnuttorque

□Inspectknivesforwearordamagesharpenorreplaceasneeded□Checkfeedrollerandmountingcapscrewtorque

□Checkfrontknifecapscrewstorque

□Inspectandgreasemeasuringwheelbearings

□Checkfeedrollerarmandcapscrewtorque

Every200—250HoursorMonthly

□Completethe50hoursorweeklyschedule□Checkandinspectupperdelimbknifepinandpincapscrewtorque

□Checkcontrolvalvemountingcapscrewtorque□Cleanandinspecttopsawarea

□Checkelectricalbracketmountcapscrewtorque□Cleanandinspecttopsawbar

□Checkandinspecttiltframepinsandbushings

□T orquetopsawmountingcapscrews

□Checkfeedrollerarmmountingcapscrewtorque□T orquemainsaw(supercut)mountingcapscrews

□Checkmainsaw(3/4in.saw)mountingcapscrewtorque□Greasemainsawfeedoutrack(supercut)

□Greasemainsawswingarmbearing(3/4in.saw)□Greasexedfeedmotorshaftsplines(hardwoodapplication)

□Checkrotatorpinionandgearsforwearandaddgrease□Checktopsawproximitysensorforloosenessordamage

Every1000Hoursor6Months

□Complete200—250hoursormonthlyschedule□Fixedfeedmotors.Checkendoatandshimmotorifneeded

□Checkallharvesterheadhydraulicpressuresettings

□T orquerotatorringgearcapscrews

□Rotatethefeedrollers

□T orquetherotatormotormountingcapscrews

□Greasexedfeedmotorshaftsplines(softwoodapplication)□Inspectdiametersensor.Rotateshaftbyhandseveraltimesboth

waystostopbuild-upofcorrosiononplates

□Checkfrontknifeandshimifneeded

Every2000HoursOrYearly

□Complete1000hoursor6-monthlyschedule□Cleanandinspectdelimbknives,feedarms,linkpins,bushings,

andmainframe

□T orquetherotatorringgeartotiltframecapscrews□Inspectrotatorpinionsupportforcracks

Model:

PIN/SerialNumber:

DeliveryDate:HourMeterReading:

Comments:

3-2-1

053122

PN=63

Loading...

Loading...