Maintenance—General

DH10862,00000E3-19-02JUN09-1/1

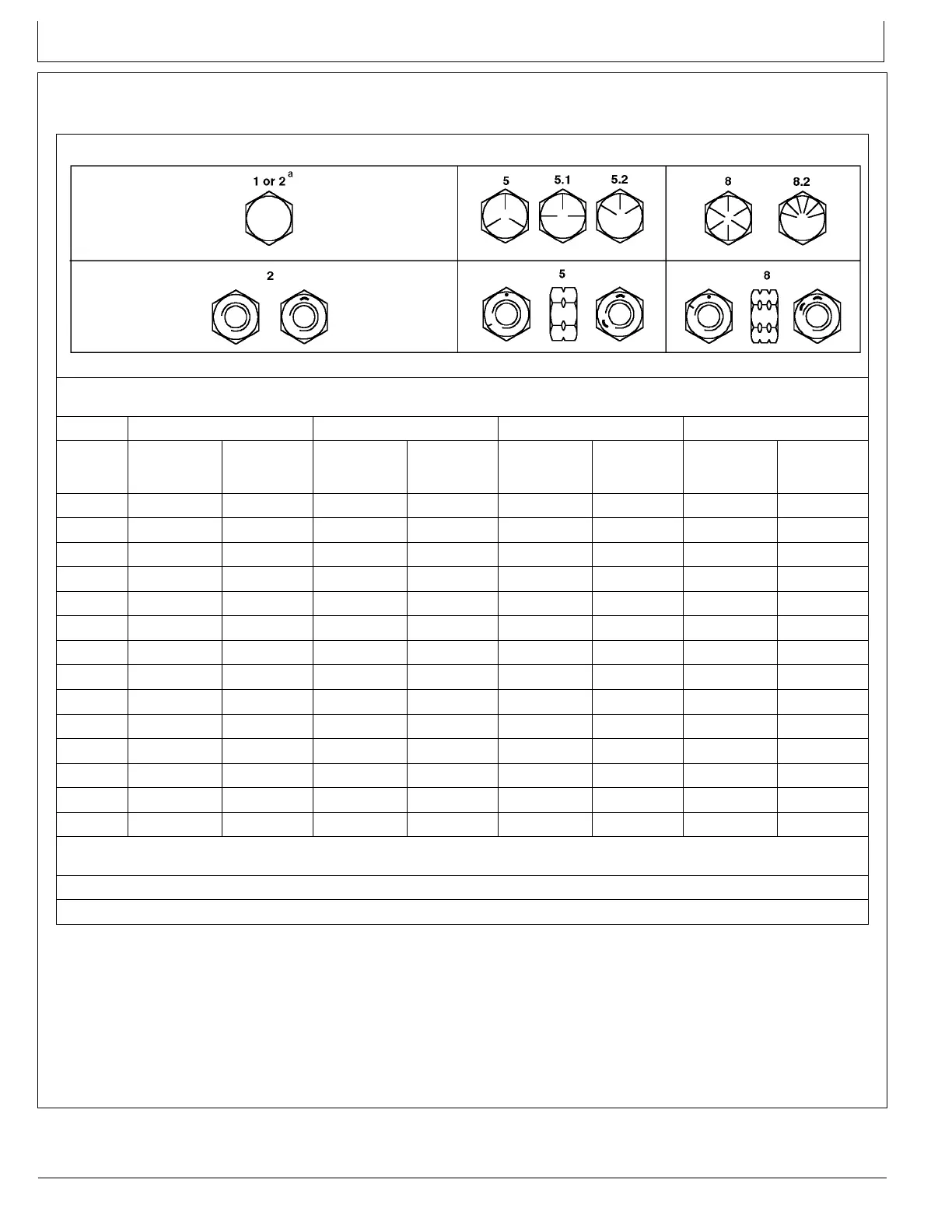

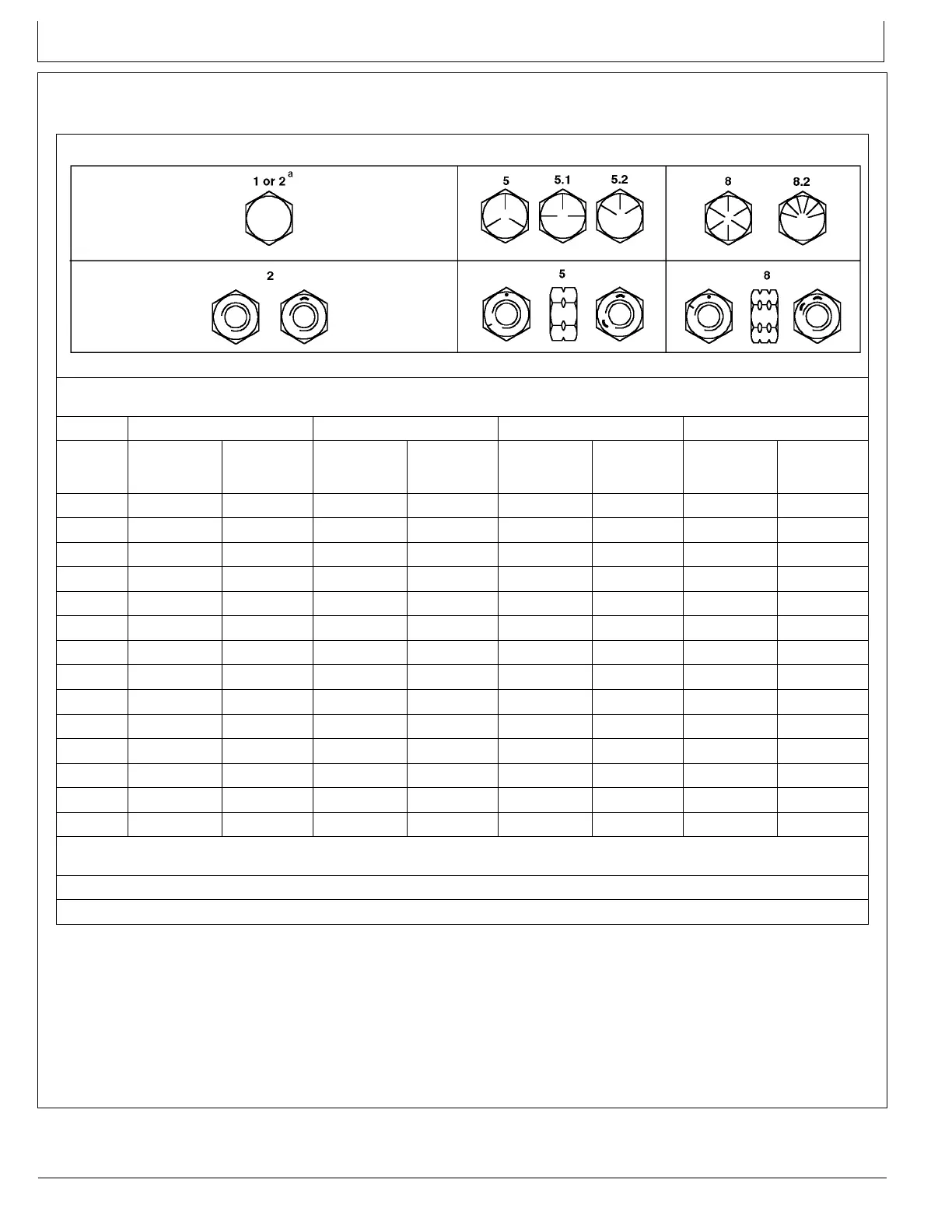

UniedInchBoltandCapScrewTorque

Values

UNIFIEDINCHBOLTANDCAPSCREWTORQUEVALUES—Toleranceis±10%unlessotherwisespecied

TORQ1A—UN—15APR13

Top—SAEGradeandHarvesterHeadMarkings;Bottom—SAEGradeandNutMarkings

Thefollowingdataisintendedtoassistinthegeneralmaintenanceofthecarrier.Itisrecommended

thatonlygrade8hardwareorbetterbeused.

Grade1(NoMark)Grade2

a

(NoMark)Grade5,5.1or5.2Grade8or8.2

Thread

Size

Lubricated

b

N·m(lb-ft)

Dry

c

N·m(lb-ft)

Lubricated

b

N·m(lb-ft)

Dry

c

N·m(lb-ft)

Lubricated

b

N·m(lb-ft)

Dry

c

N·m(lb-ft)

Lubri-

cated

b

N·m

(lb-ft)

Dry

c

N·m(lb-ft)

1/43.8(2.8)4.7(3.5)6(4.4)7.5(5.5)9.5(7)12(9)13.5(10)17(12.5)

5/167.7(5.7)9.8(7.2)12(9)15.5(11.5)19.5(14.5)25(18.5)28(20.5)35(26)

3/813.5(10)17.5(13)22(16)27.5(20)35(26)44(32.5)49(36)63(46)

7/1622(16)28(20.5)35(26)44(32.5)56(41)70(52)80(59)100(74)

1/234(25)42(31)53(39)67(49)85(63)110(80)120(88)155(115)

9/1648(35.5)60(45)76(56)95(70)125(92)155(115)175(130)220(165)

5/867(49)85(63)105(77)135(100)170(125)215(160)240(175)305(225)

3/4120(88)150(110)190(140)240(175)300(220)380(280)425(315)540(400)

7/8190(140)240(175)190(140)240(175)490(360)615(455)690(510)870(640)

1

285(210)360(265)285(210)360(265)730(540)920(680)1030(760)1300(960)

1-1/8400(300)510(375)400(300)510(375)910(670)1150(850)1450(1075)1850(1350)

1-1/4570(420)725(535)570(420)725(535)1280(945)1630(1200)2050(1500)2600(1920)

1-3/8750(550)950(700)750(550)950(700)1700(1250)2140(1580)2700(2000)3400(2500)

1-1/2990(730)1250(930)990(730)1250(930)2250(1650)2850(2100)3600(2650)4550(3350)

a

Grade2appliesforhexcapscrews(nothexbolts)upto6in.(152mm)long.Grade1appliesforhexcapscrewsover6in.(152mm)long,and

forallothertypesofboltsandscrewsofanylength.

b

"Lubricated"meanscoatedwithalubricantsuchasengineoil,orfastenerswithphosphateandoilcoatings.

c

"Dry"meansplainorzincplatedwithoutanylubrication.

DONOTusethesevaluesifadifferenttorquevalueortightening

procedureisgivenforaspecicapplication.T orquevalueslistedare

forgeneraluseonly.Checktightnessoffastenersperiodically.

Shearboltsaredesignedtofailunderpredeterminedloads.Always

replaceshearboltswithidenticalgrade.

Fastenersshouldbereplacedwiththesameorhighergrade.If

highergradefastenersareused,theseshouldonlybetightenedto

thestrengthoftheoriginal.

Makesurefastenerthreadsarecleanandthatyouproperlystartthread

engagement.Thiswillpreventthemfromfailingwhentightening.

Tightenplasticinsertorcrimpedsteel-typelocknutstoapproximately

50percentofthedrytorqueshowninthechart,appliedtothenut,

nottothebolthead.Tightentoothedorserrated-typelocknutstothe

fulltorquevalue.

3-3-3

053122

PN=73

Loading...

Loading...