Optional glass capillary sprayer 4-11

To optimize the glass capillary sprayer

1. Set the NanoFlow gas pressure to 0.3 bar and the cone gas to 40 L/h.

2. Ascertain that sample is flowing by observing a droplet on the tip.

Tip: If you cannot observe a droplet, increase the pressure briefly, up to

a maximum of 1.5 bar, and then return the pressure to 0.3 bar.

3. If you observe a droplet, continue the procedure at step 9.

Requirement: If you do not observe a droplet, in the MassLynx Tune

window, ensure the Capillary parameter is set to 0 V, and follow step 4

through step 8.

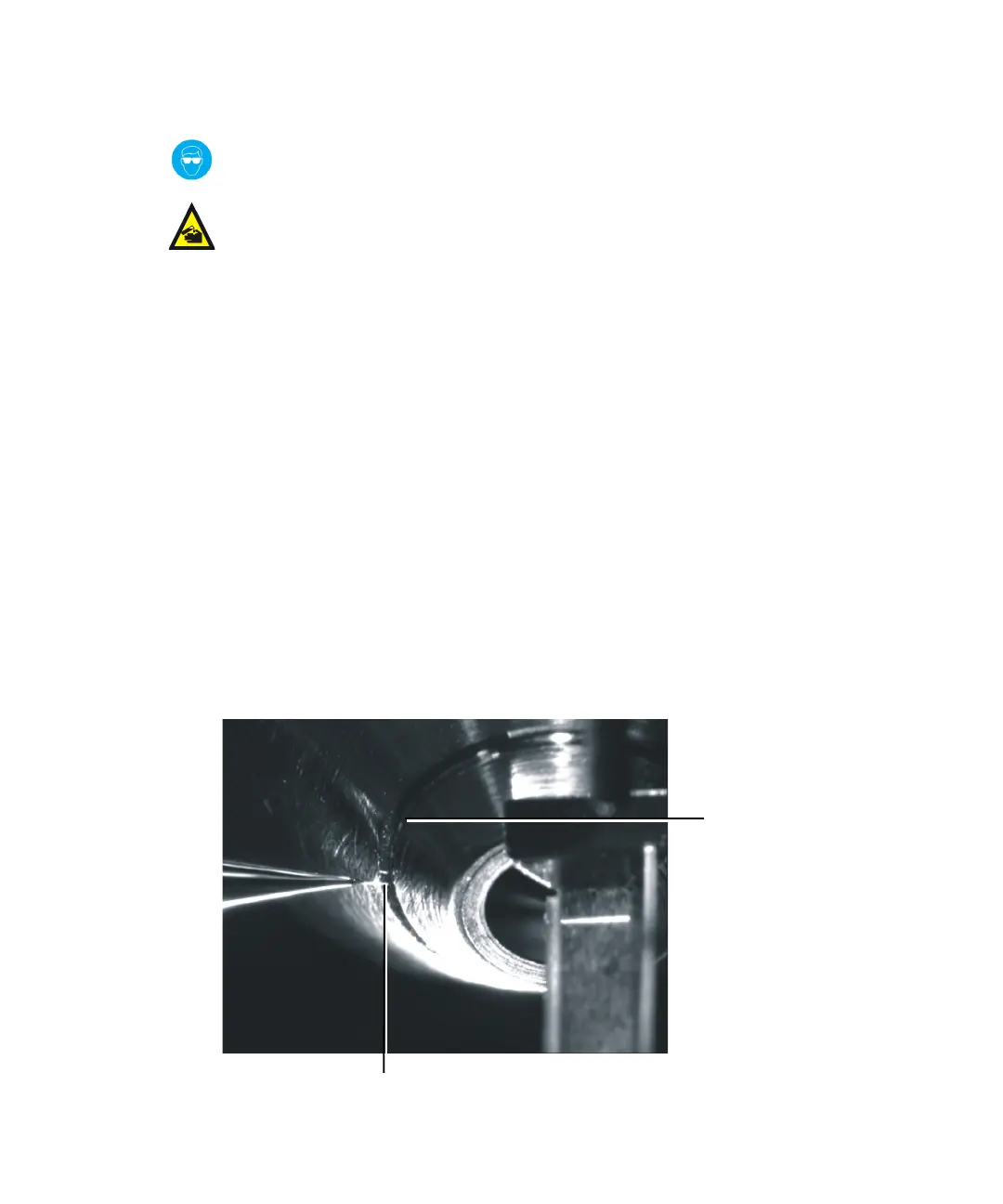

4. Move the sprayer back and to the left-hand side until the tip aligns with

the groove on the cone.

Tip: Aligning is best done while viewing from the front of the source.

5. While watching the camera image, carefully move the tip forward

toward the groove, until it touches, and a small piece of the glass

capillary shears off.

Warning: To avoid eye injuries, always wear eye protection when cutting

fused silica.

Warning: To avoid injury from trace chemicals on the probe, always

wear chemical-resistant, powder-free gloves.

Groove

Glass capillary

Loading...

Loading...