Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

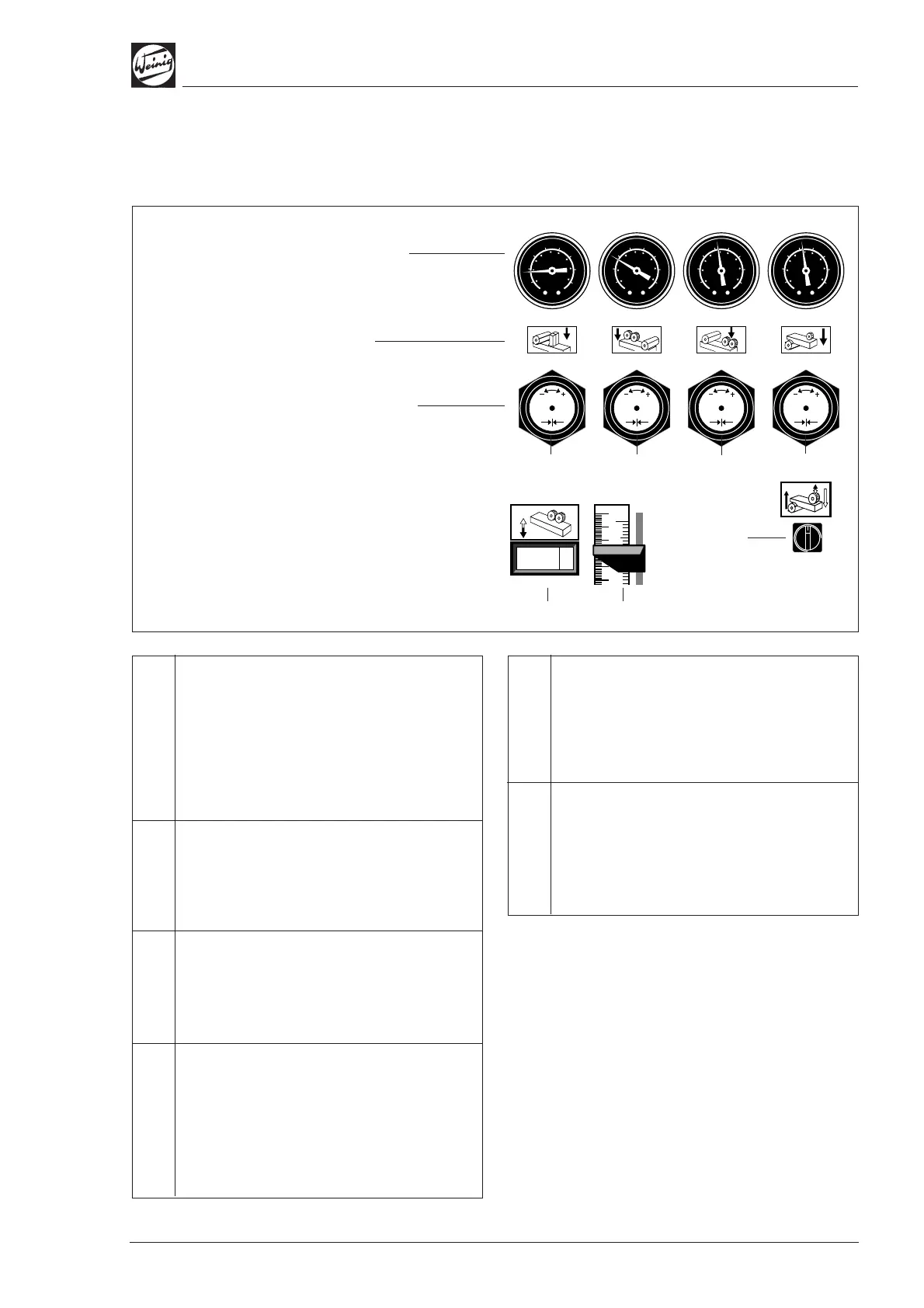

Operating elements

2-7Profimat 23 E

P 5 Cycled infeed roller (optional)

Left = Cycle infeed roller

downwards, surfacing

Right = Cycle infeed roller upwards,

straightening

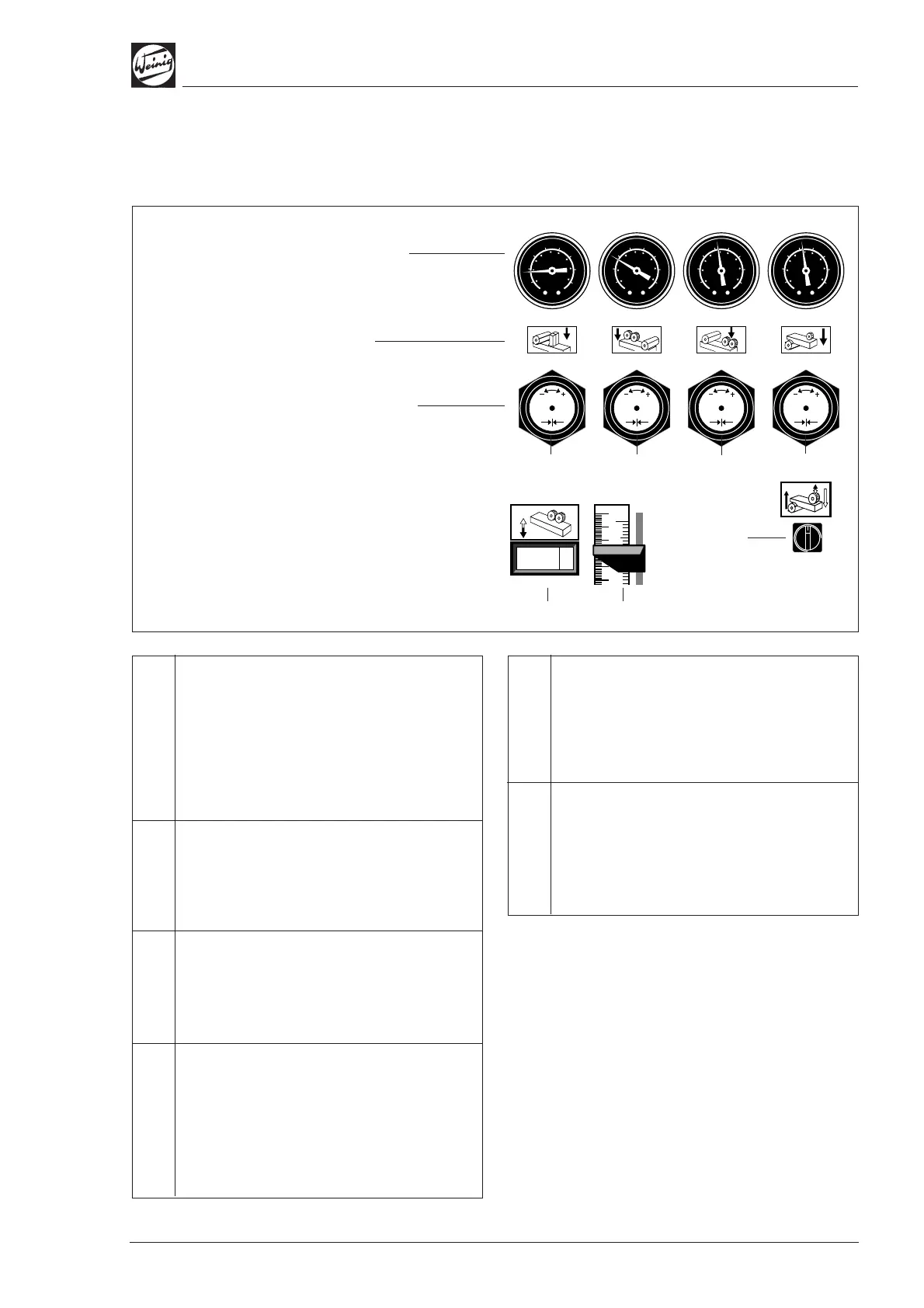

Feed rollers, height indication

B 1a Bottom edge of feed roller in front of top

spindle to table, height indication on timber

infeed

B 1b (optional) instead of B 1a

2

4

6

8

10

12

14

16 2

4

6

8

10

12

14

16

2

4

6

8

10

12

14

16

2

4

6

8

10

12

14

16

Pneumatic control panel

P 1 Pressure circuit 1, transport roller

before 1st bottom spindle

(straightening) (optional) Hold-down

pressure of transport rollers before the

straightening spindle, raw timber

Basic setting:

Workpieces < 100 x 100 mm: appr. 1 – 4 bar

Workpieces > 100 x 100 mm: appr. 3 – 6 bar

P 2 Pressure circuit 2, steel feed rollers

Set hold-down pressure of the steel rollers

before the top spindle, raw timber

Basic setting: approx. 2 – 3 bar

P 3 Pressure circuit 3, rubber feed rollers

Hold-down pressure of the rubber rollers after

the top spindle, finished timber

Basic setting: approx. 2 – 3 bar

P 4 Pressure circuit 4, hold-down pressure of

chipbreaker before top spindle (optional)

Hold-down pressure of chipbreaker before top

spindle, raw timber

Basic setting: approx. 2 – 3 bar

P 1

P 5

P 4 P 3 P 2

0000 0

26

10

B 1aB 1b

Pressure gauge

Hold-down pressure

of feed rollers

Symbol

for pressure circuit

Pressure control

Pull knob out to adjust

Loading...

Loading...