Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-1Profimat 23 E

Principle of basic settings

This chapter summarizes the most important

settings. A more detailed description can be

found in the following chapters.

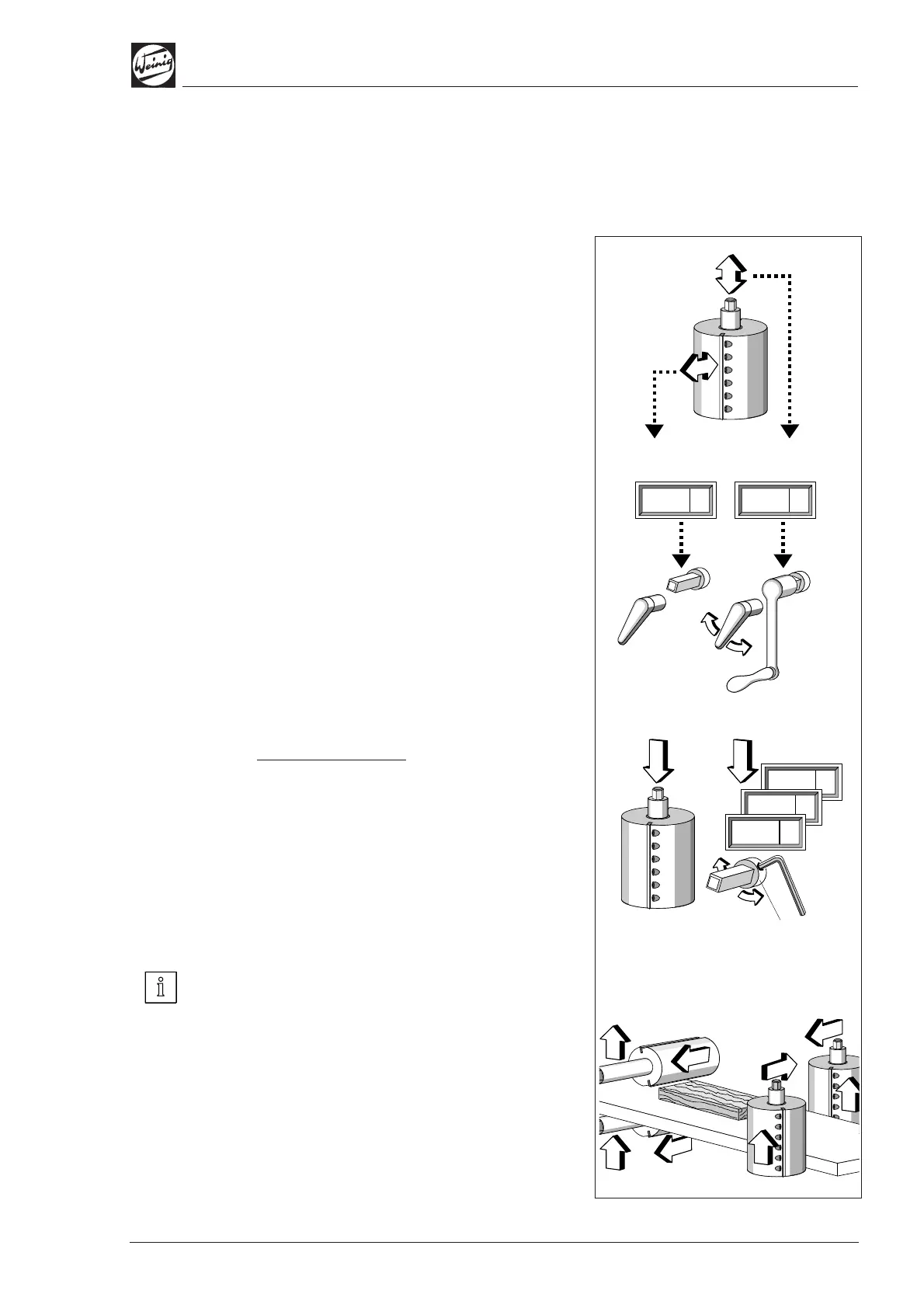

Adjusting spindles

Spindles can be adjusted in two directions: axially

in parallel to the axis or radially in parallel to the

radius. The spindle position can be read off on

the numerical indicator.

1. Loosen spindle clamp (1).

2. Adjust spindle via crank handle (2) and

retighten spindle clamp (1).

Basic setting and calibration of the

numerical indicators

After setting the spindle shaft in relation to the

setting straight edge, for example, the mechanical

counter must be set as follows:

3. Loosen clamping screw (3) on adjusting ring.

4. Turn adjusting ring to the required setting.

The direction in which the numerical

indicator was last turned must be the same as

the direction of rotation of the spindle (play

in the numerical indicator).

5. Tighten clamping screw (3).

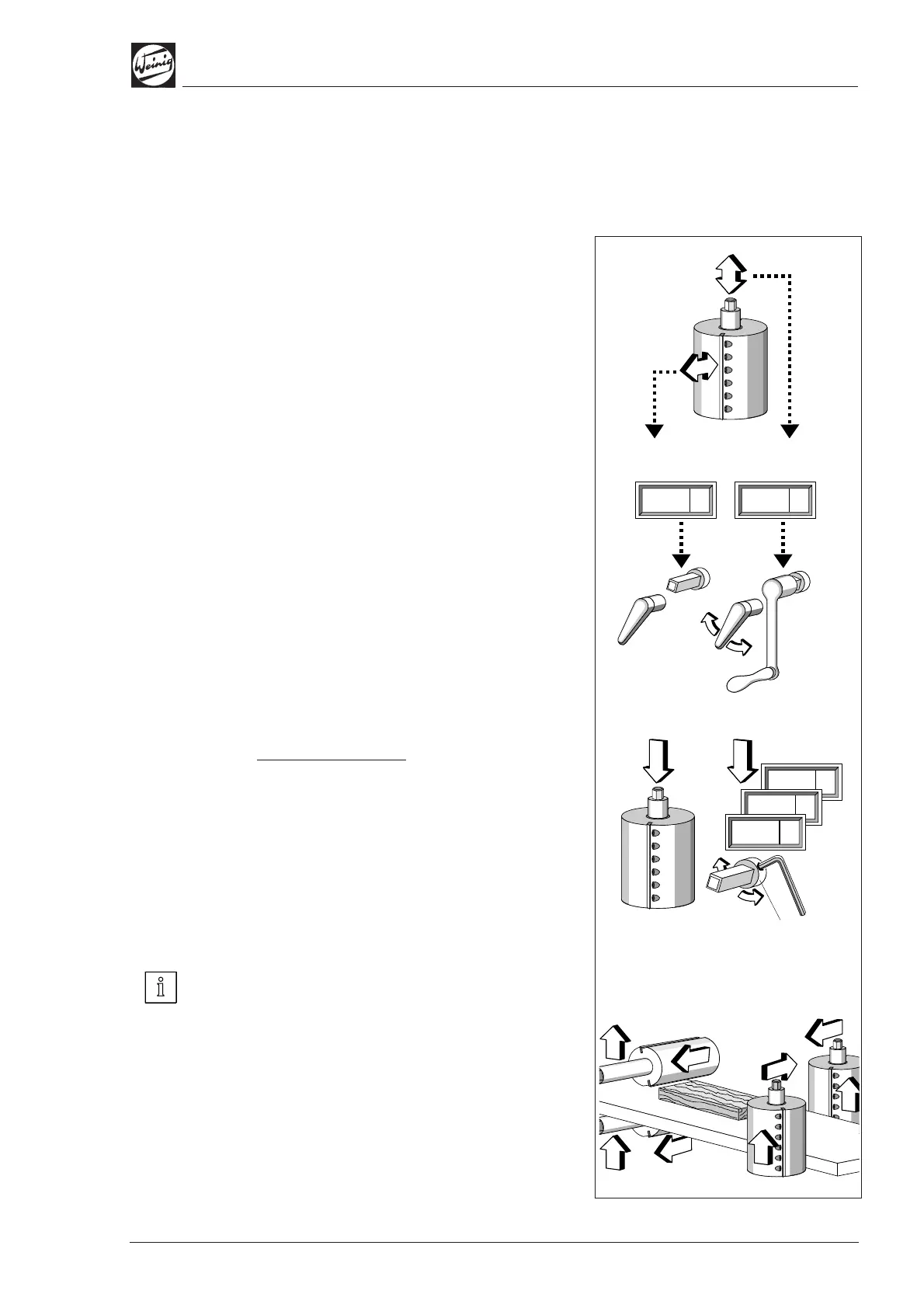

Adjustment procedure

In order to eliminate the spindle play, the bottom,

right-hand and left-hand spindles must always be

set to their final position by turning towards the

workpiece.

The top spindles and feed, on the other hand,

must always be set to their final position from

bottom to top in order to eliminate the spindle

play.

0010 0

0009 0

0062 5 0010 0

0000 0

(1)

(2)

(3)

Loading...

Loading...