Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-9Profimat 23 E

0020 0

0000 0

0020 0

0063 0

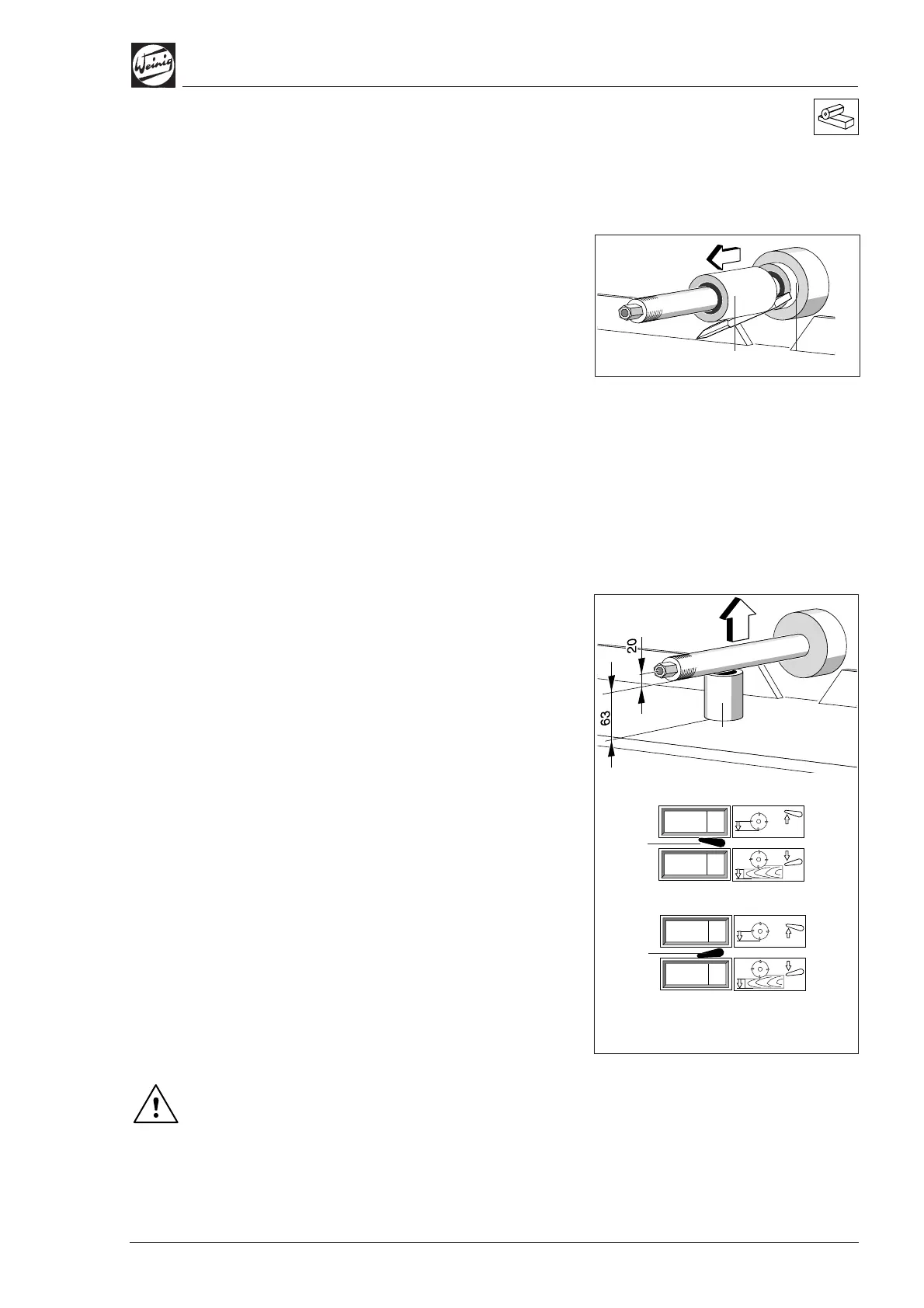

Top spindle

Axial basic setting

• Clamp setting straight edge between spacer

ring (1) 10.0 mm (0.394") and spindle ring (2)

63.0 mm (2.480").

• Release clamp and axially adjust spindle until

setting straight edge is aligned with fence.

• Set numerical indicator to 10.0 mm (0.394")

(see page 4-1).

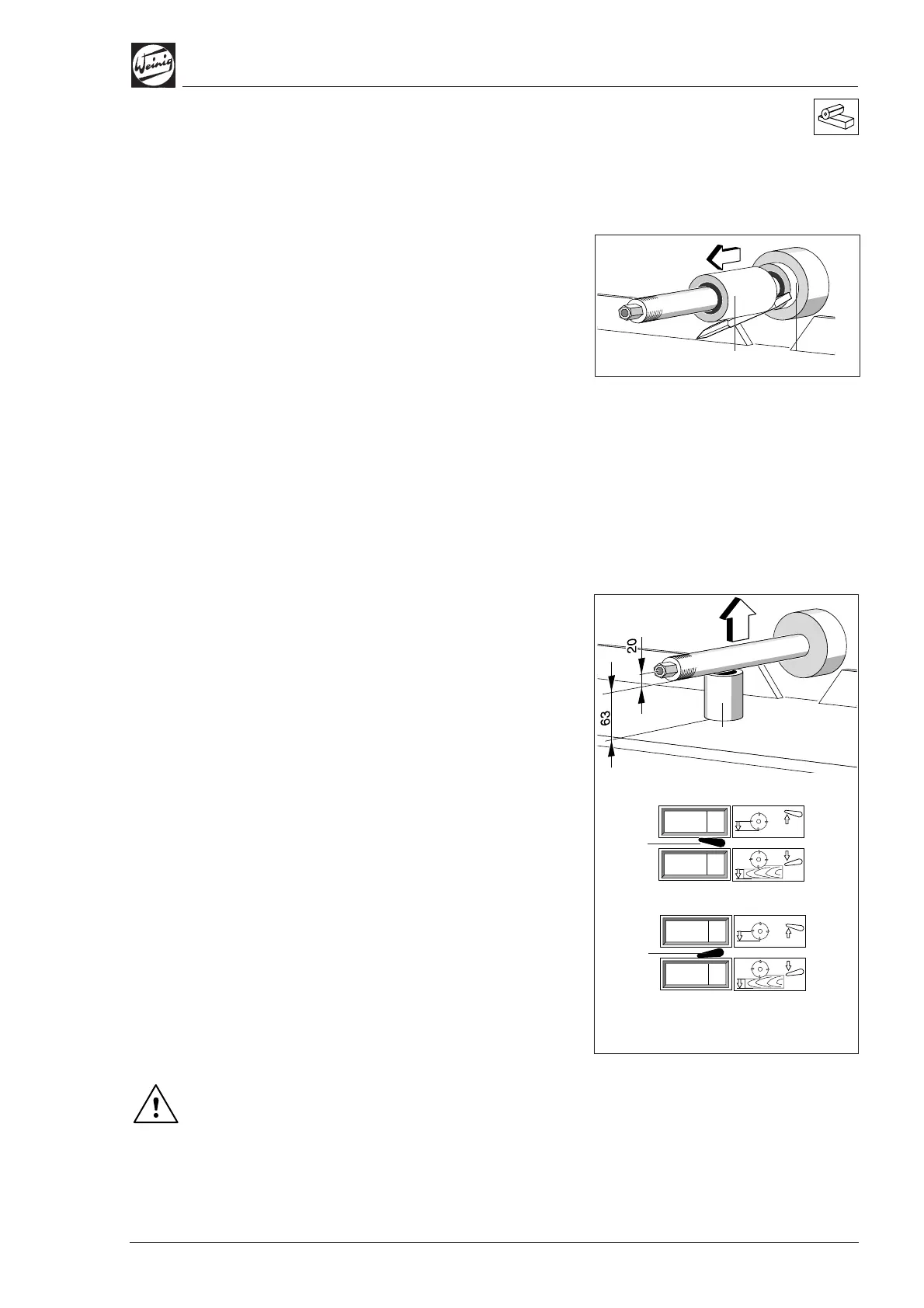

Radial basic setting

• Raise pressure elements before and after top

spindle if necessary so that they do not rest on

the machine table when adjusting settings.

• Plane a test piece and measure timber height.

• Set numerical indicator to measured value

(see page 4-1).

Machines with two-fold indication (optional):

(A) Spindle radius:

• Lever (3) up.

• Set upper indicator to 20.0 mm (0.787") or half

of spindle diameter by means of the switch and

button.

(B) Spindle ring height:

• Lever (3) down.

• Place measured spindle ring (1) – 63.0 mm

(2.480") in this case – on machine table (2).

• Release spindle clamp and move spindle up

towards spindle ring until spindle ring can just

be moved under the spindle

• Set lower indicator to 63.0 mm (2.480") (see

page 4-1).

Note any chip removal on the last bottom spindle.

Set timber height, change tool radius

The timber height and tool radius can be set

directly, as with the left-hand spindle, when these

basic settings have been obtained.

The adjusting spindle must not be turned

when changing lever (3) from radius to width

or height indication! This applies for both

motor-driven and manual adjustment.

(2)

(1)

(2)

(1)

(A)

(B)

(3)

(3)

Loading...

Loading...