Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-10 Profimat 23 E

3

62,5

0062 5

0062 5

(1) (2)

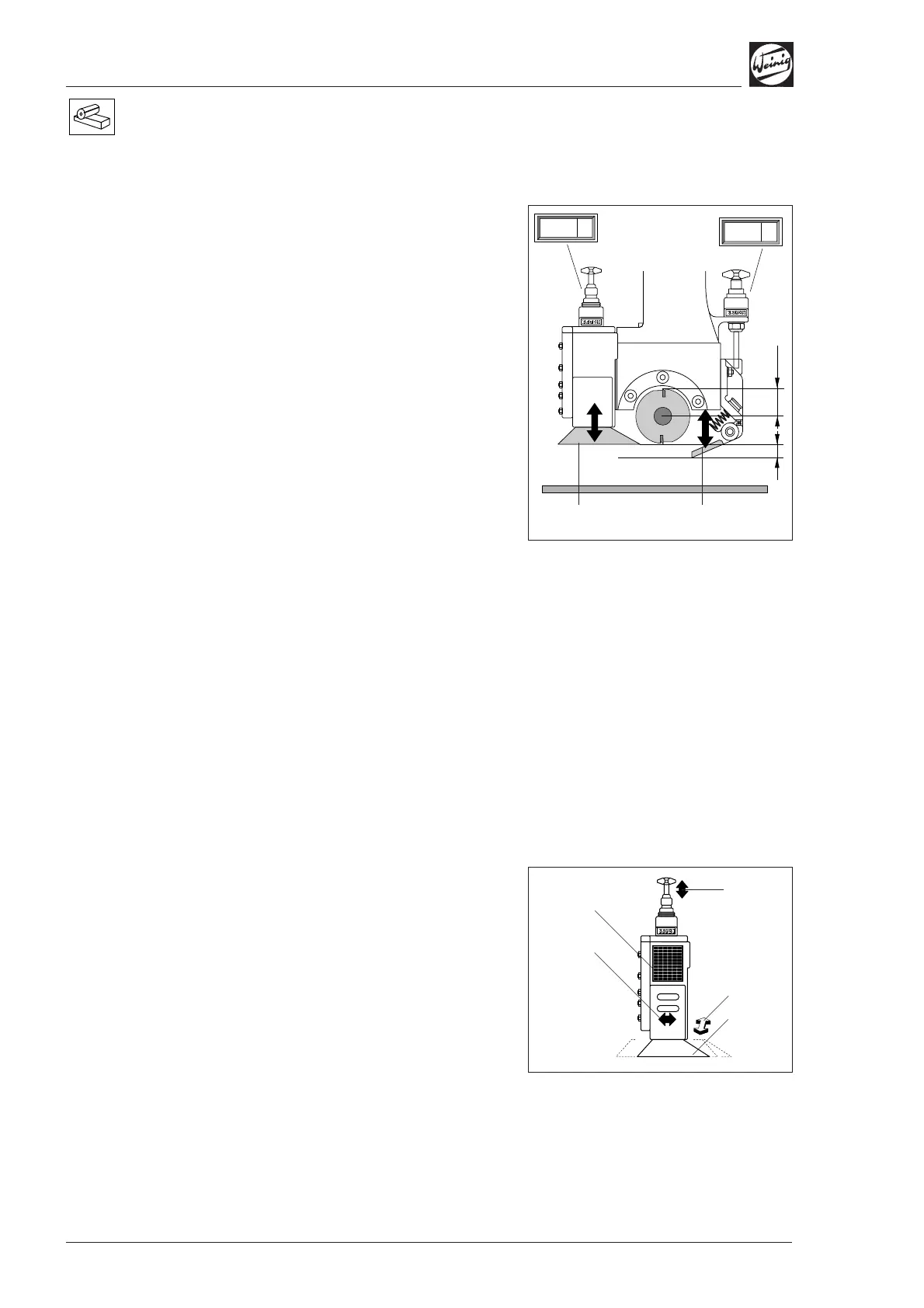

Basic setting of top pressure

elements

• Set pressure shoe (1) after the spindle to the

smallest tool cutting circle by holding the

setting straight edge against the underside of the

pressure shoe.

• Release clamping screw on numerical indicator

(optional) and set indicator to tool radius, in this

case 62.5 mm (2.46").

• Then set chipbreaker (2) before tool so that it is

3 mm (0.125") below the tool.

• Hold setting straight edge underneath chip-

breaker and adjust pressure element in relation

to setting straight edge.

• Set chipbreaker 3 mm (0.125") lower in

accordance with numerical indicator (if

installed). This automatically sets a pretension

of 3 mm (0.125").

• Release clamping screw on numerical indicator

and set tool radius, in this case 62.5 mm

(2.460").

Pressure shoe (1) and chipbreaker (2) can now be

set to new tool cutting circles without delay in

accordance with the numerical indicator.

When the basic settings have been made for the

top spindle and upper pressure elements, the

entire assembly (spindle, chipbreaker, feed) must

be set to the required workpiece height.

Pressure shoe after top spindle

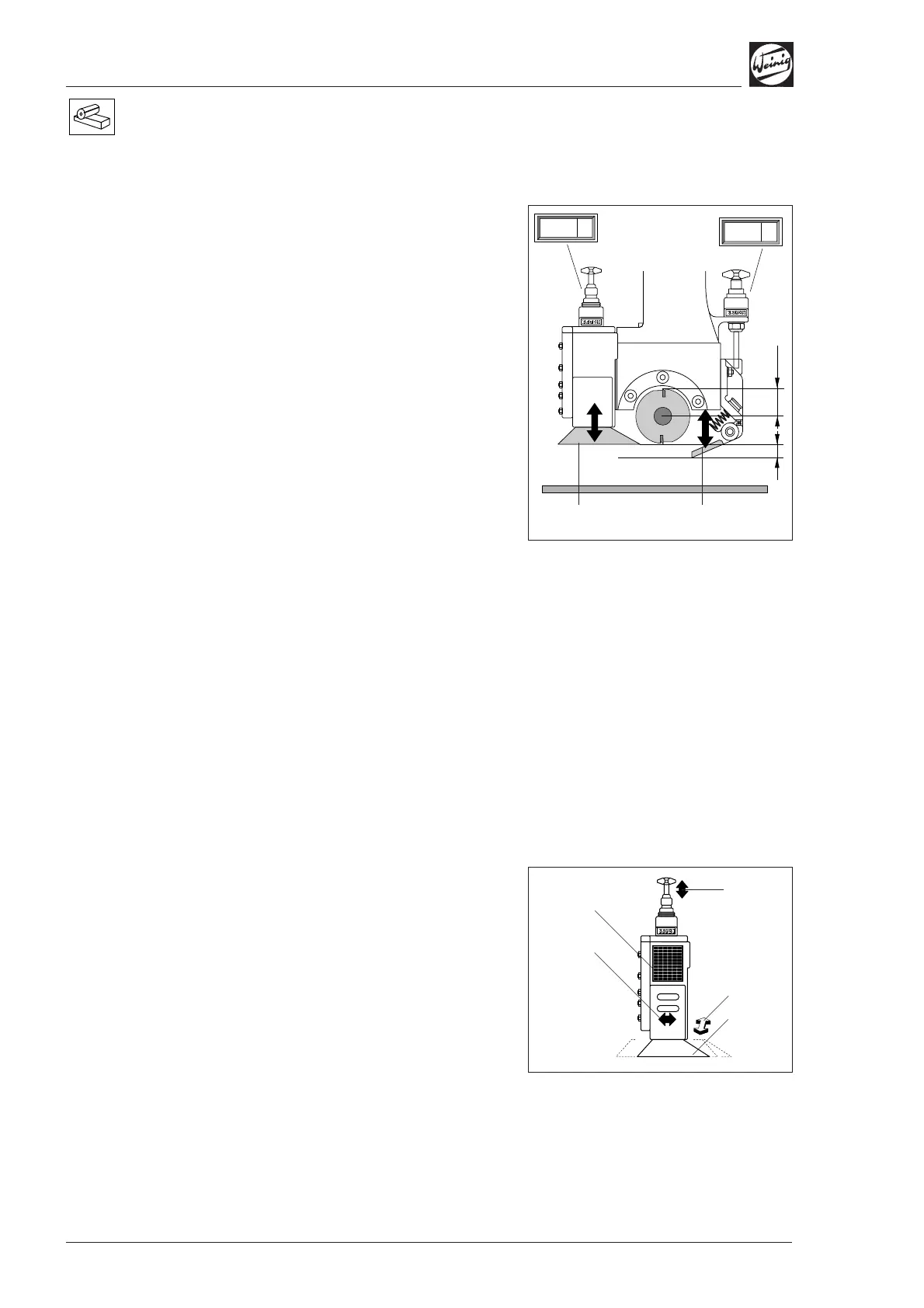

• Set pressure shoe (1) to minimum tool cutting

circle up/down (2) and to maximum tool cutting

circle forwards/backwards (3) for profile tools.

• If a profile guide is fitted, it must be set

forward/backward in relation to the profile.

Ensure that the pressure shoe does not press

against the machine fence when setting is

complete.

• Set hold-down pressure on pressure shoe as

shown in table (5).

(5)

(2)

(1)

(3)

(4)

Loading...

Loading...