Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Setting up profiles

5-2 Profimat 23 E

Set-up variation –

planing a test piece

Adjust the profile tools to roughly the correct

position with the aid of the setting straight edge in

radial direction and as appears correct in axial

direction.

Example, top spindle

• Set all profile spindles to roughly the correct

position.

• Plane a test piece.

• Establish the axial or radial spindle correction

values from the required and actual values:

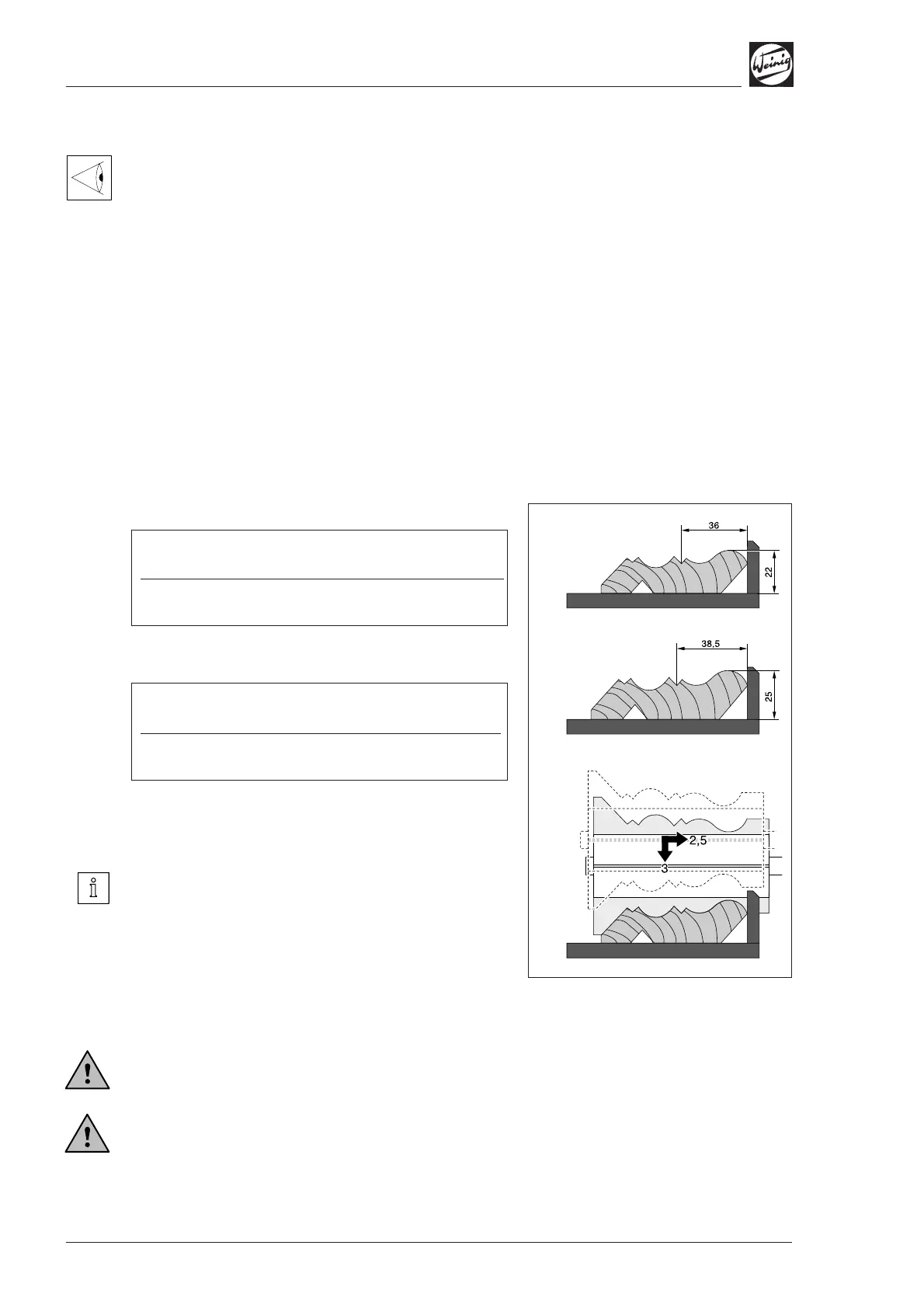

Example – radial

Example – axial

• Adjust spindles 3 mm (0.118") downwards and

2.5 mm (0.098") to the rear.

Recommendation:

• Note value shown on numerical indicator on the

tools.

These settings can be reused when the tools are

fitted again and have not been resharpened,

provided that the basic setting remains

unchanged.

When cutting the test piece, feed the raw

timber through the machine cautiously at

inching speed.

Ensure that the maximum chip removal is not

exceeded and that the workpiece rests squarely

against the fence.

Required value, profile (1). 22.0 mm (0.866")

– Actual value, test piece (2) .25.0 mm (0.984")

= Spindle correction (3) ...........3.0 mm (0.118")

(1)

(2)

(3)

Required value, profile (1). 36.0 mm (1.417")

– Actual value, test piece (2) 38.5 mm (1.516")

= Spindle correction (3) ...........2.5 mm (0.098")

Loading...

Loading...