Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Troubleshooting

7-2 Profimat 23 E

Determining the cause of

snipes

Recommendations for trouble-

shooting

Mark faults

Immediately upon removal of the workpiece:

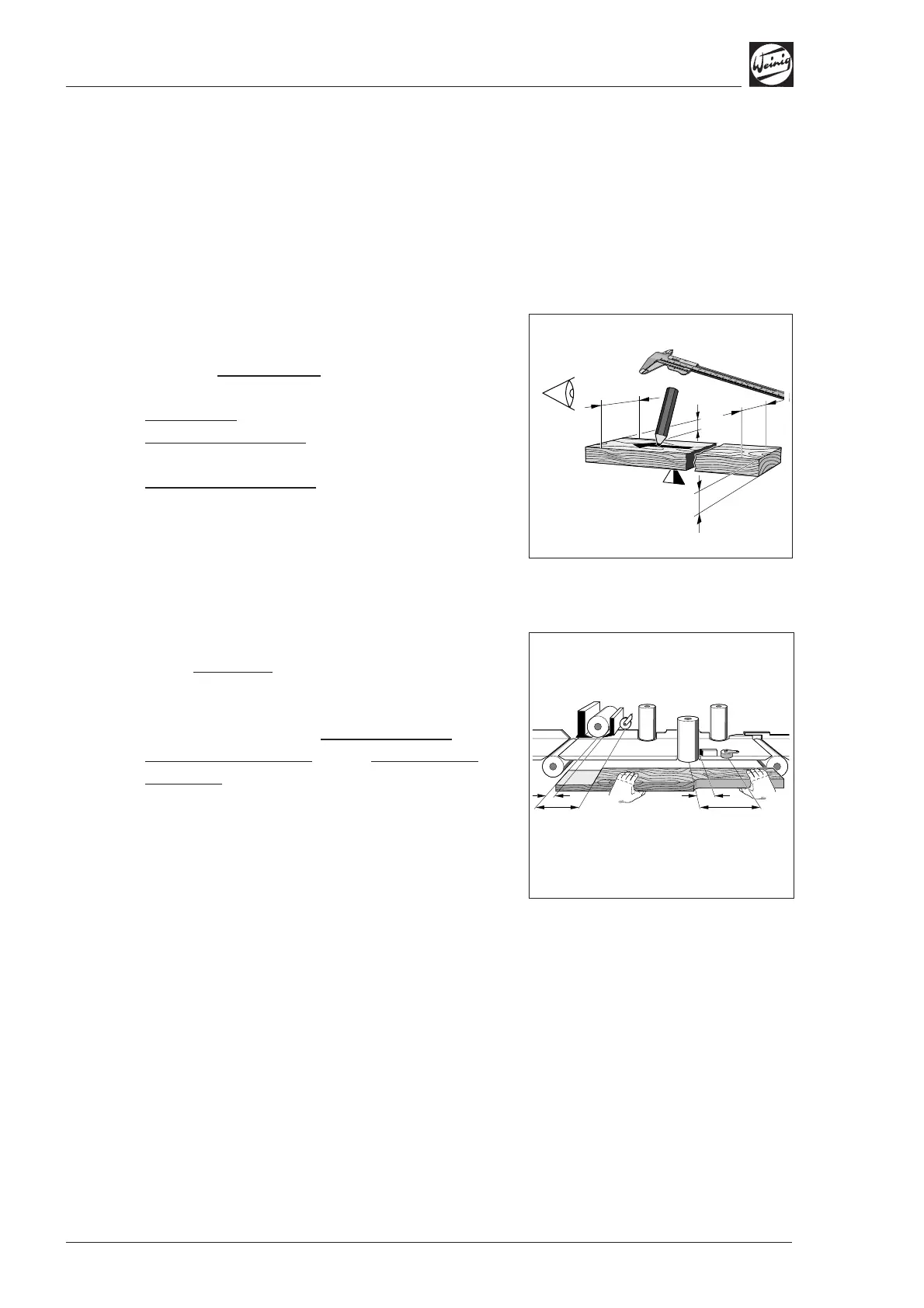

• Mark the feed direction and the position of the

workpiece in the machine.

• Mark snipes.

• Check for parallelism: Measure the width/height

on the infeed and out-feed side.

• Check for twist or bow: Place the workpiece

on the level bottom straightening table.

Workpiece and machine

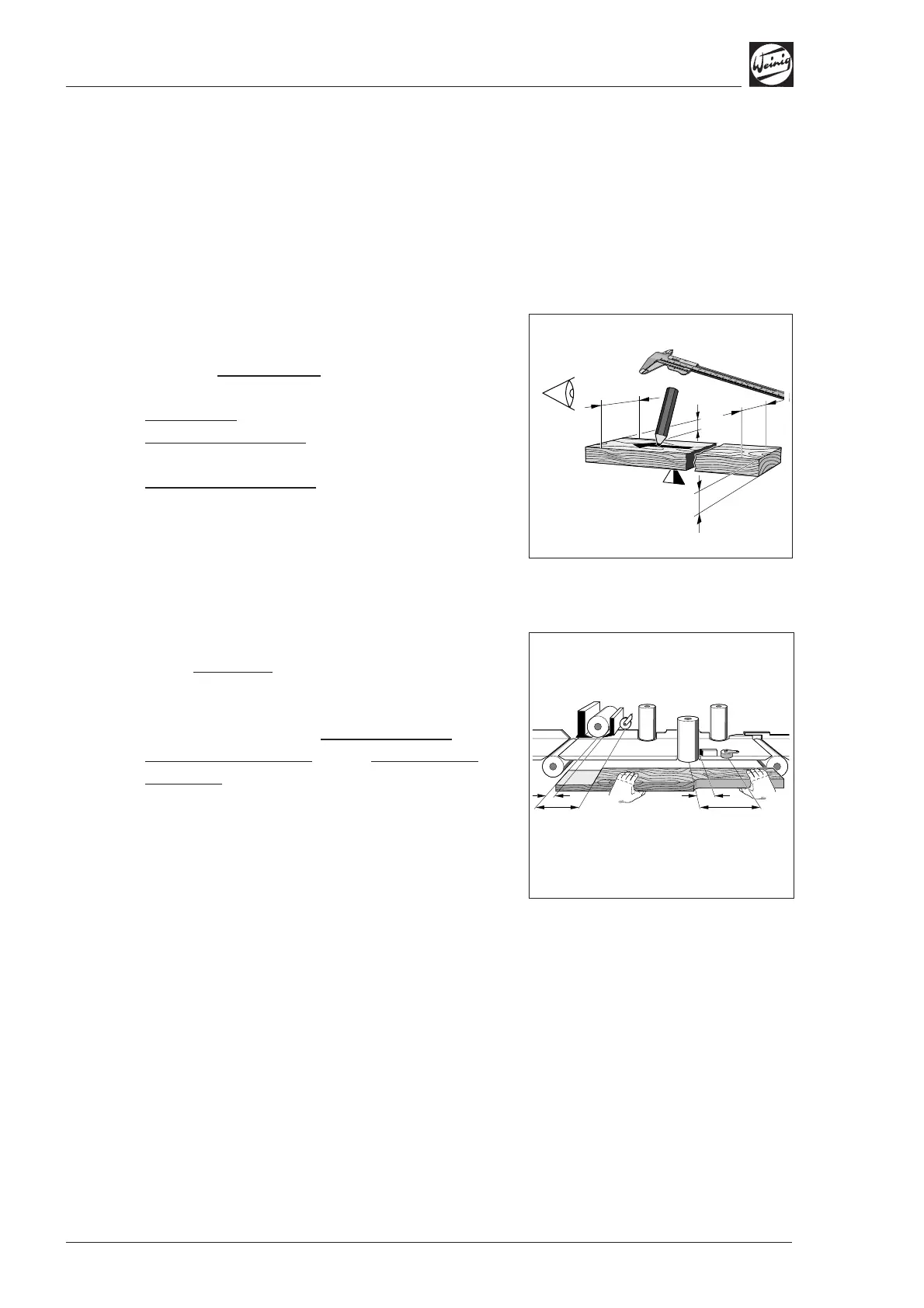

• Hold the trial workpiece next to machine and

check which tool caused the snipe.

• Has the basic set-up of the spindle been prop-

erly performed? Check which hold-down

adjacent to the spindle, which pressure roller or

feed roller might have caused the snipe.

The component responsible for the snipe can be

located by comparing the length of snipe and

the distance between the spindle axis and the

component (see Page 7.3).

Mark workpiece

Determine cause of fault

Loading...

Loading...