Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Troubleshooting

7-3Profimat 23 E

(2)

(3)

(1)

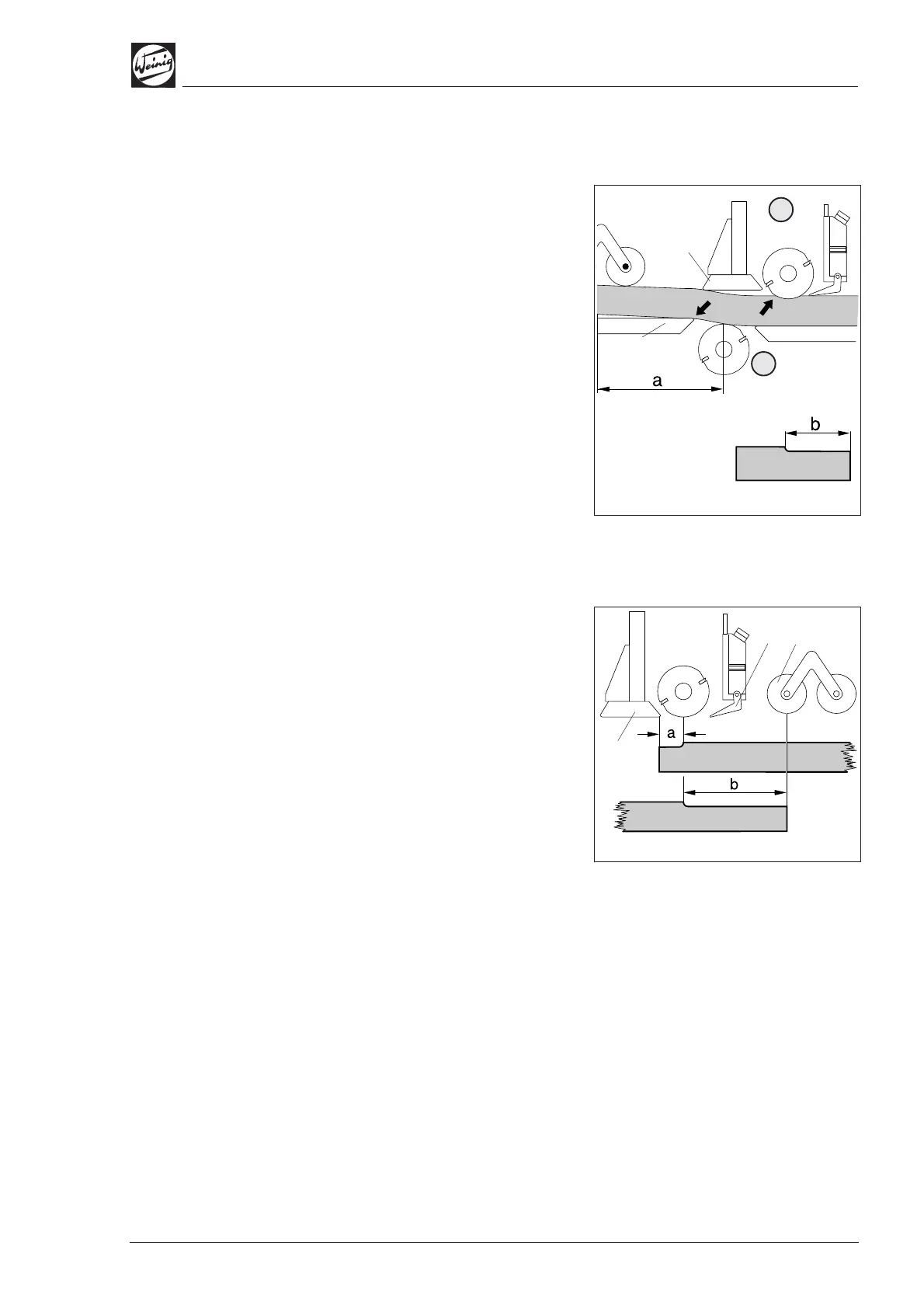

Example: Faults due to spindle

Situation:

The second bottom spindle is positioned too low,

thus affecting the correctly set top spindle.

Cause of defect (A):

The timber knocks against the table plate (1) and

moves diagonally upwards and away from it.

Result: Snipes on the entire underside (a) and

workpieces which are neither parallel nor

dimensionally accurate.

Cause of defect (B):

Pressure shoe (2) lifts off due to the angular travel

of the timber. Consequence: snipe on top (b).

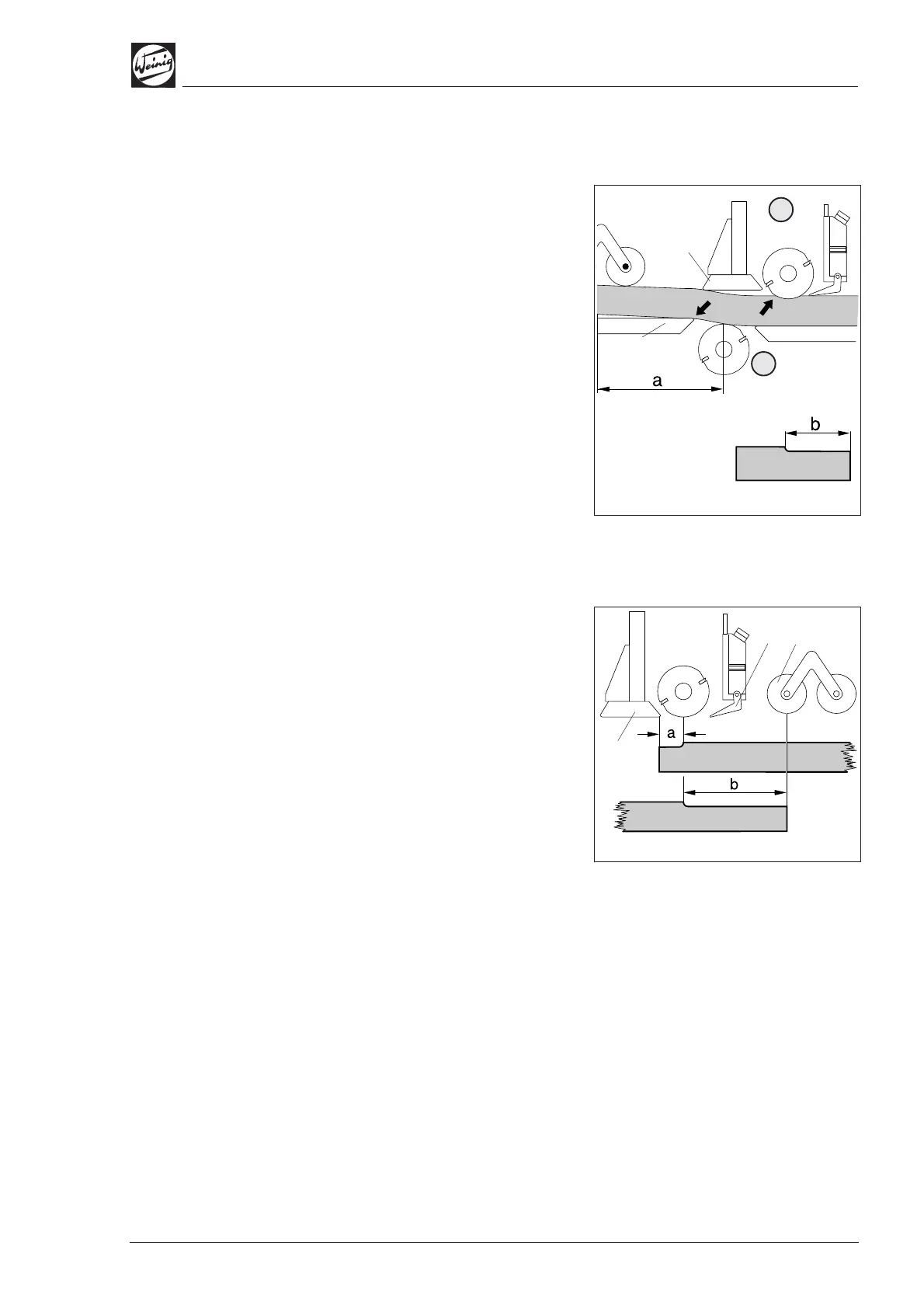

Example: Fault due to pressure

element

Situation:

Pressure element (2) before top spindle has been

set incorrectly.

Position snipe under middle of tool. The distance

between the point of tool action and the pressure

element indicates which component has been set

incorrectly.

Snipe (a) at beginning of timber:

Pressure shoe (1) presses timber downwards.

Pressure element (2) has been set too lightly so

that the timber springs upwards. Consequence:

snipe mark at the beginning of the timber.

Snipe (b) at end of timber:

The end of the timber emerges from the feed

roller (3). Pressure element (2) has been set too

lightly so that the timber springs upwards.

Consequence: snipe mark at the end of the timber.

(2)

B

(1)

A

Loading...

Loading...