Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-7Profimat 23 E

0020 0

0000 0

0020 0

0063 0

Left-hand spindle

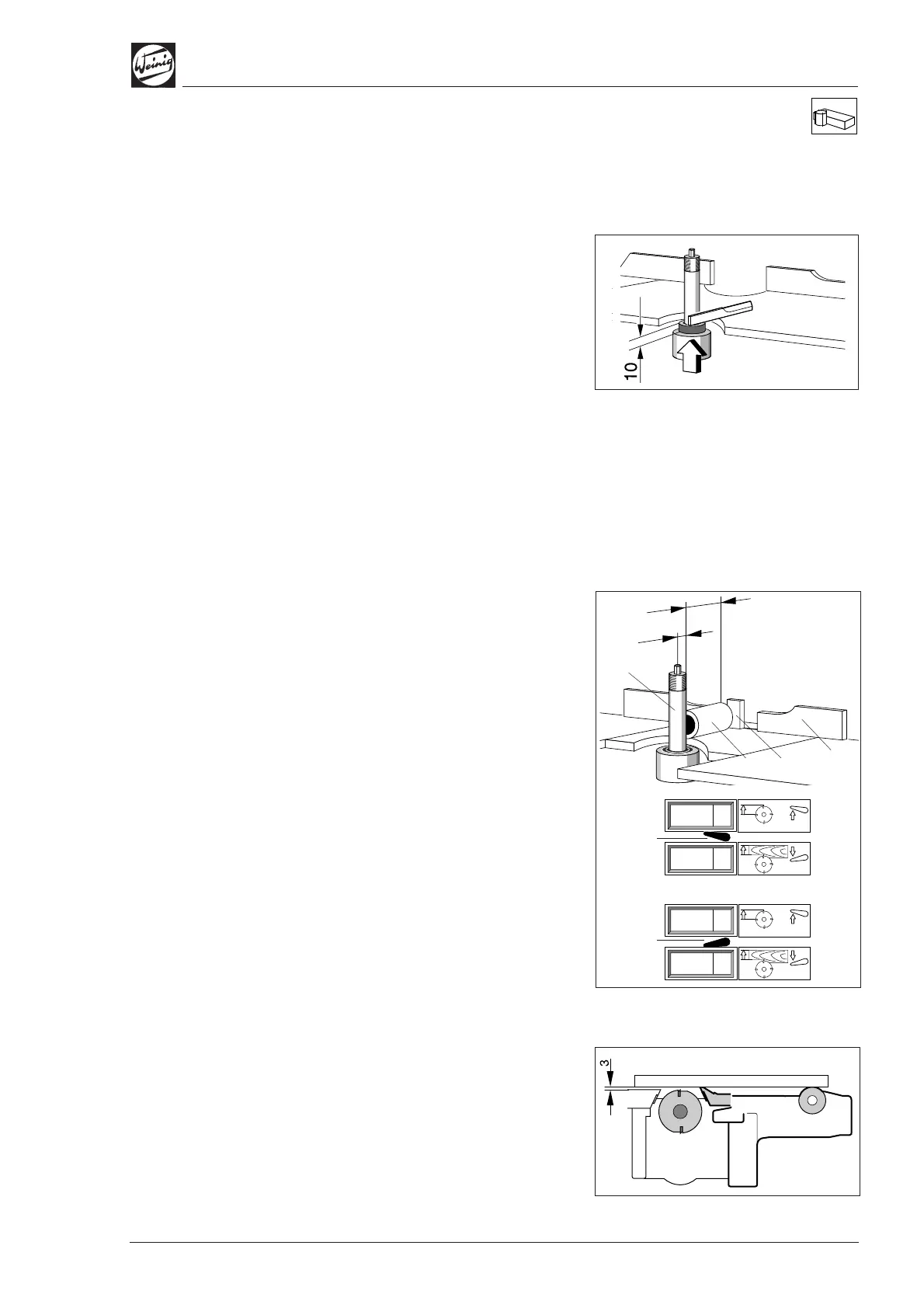

Axial basic setting

• Position spacer ring 10.0 mm (0.394") on

spindle.

• Position setting straight edge on spacer ring.

• Release clamp and adjust spindle in axial

direction until setting straight edge is aligned

with table.

• Set numerical indicator to 10.0 mm (0.394")

(see page 4-1).

Adjust for any chip removal on the last bottom

spindle (see page 4-12).

Radial basic setting

• Plane a test piece and measure timber width.

• Set numerical indicator to measured value (see

page 4-1).

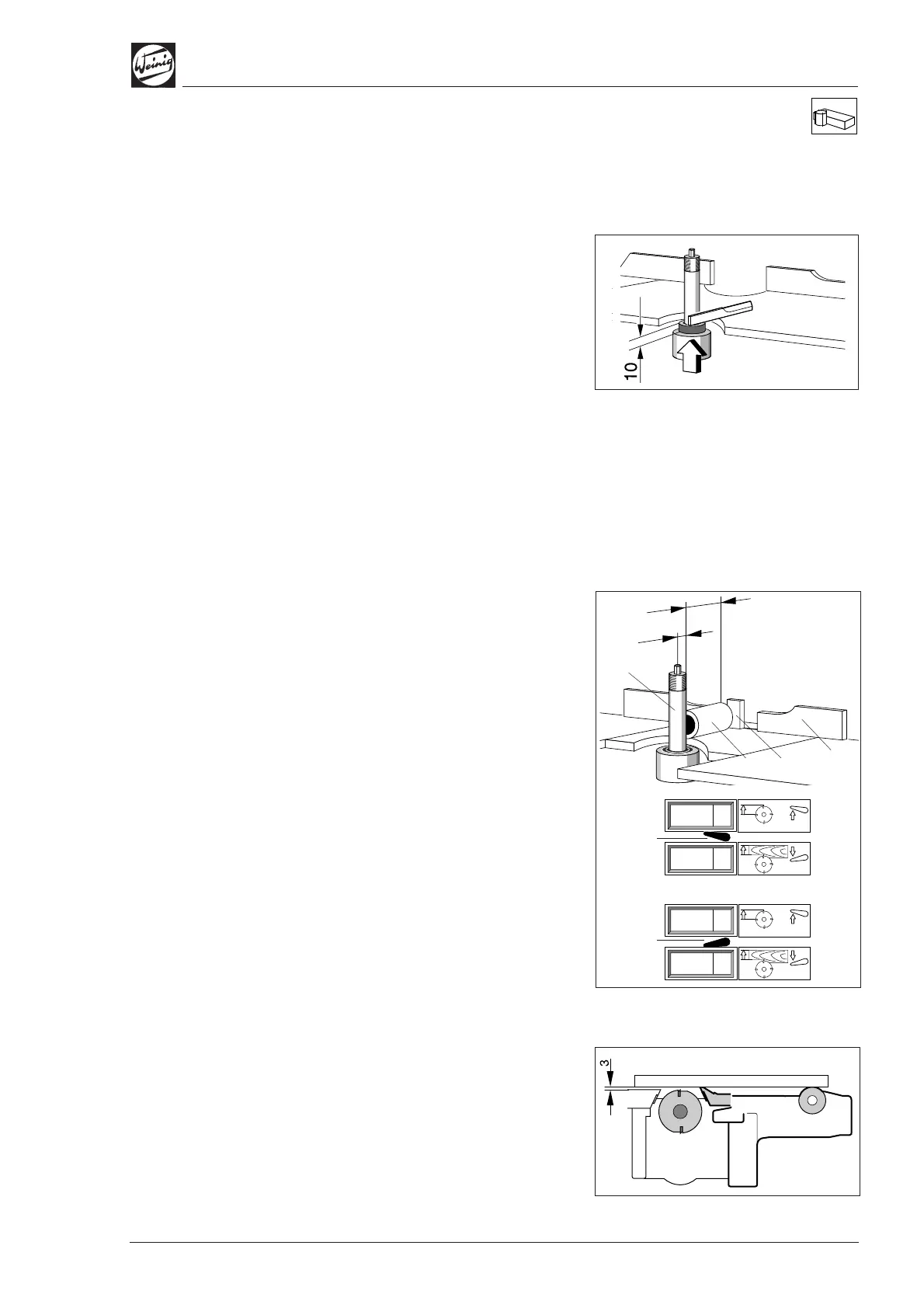

Machines with DigiSet counter (optional):

(A) Spindle radius

• Move lever (5) upwards.

• Set upper indicator to 20.0 mm (0.787") by

means of crank handle.

(B) Spindle ring length

• Move lever (5) downwards.

• Place measured spindle ring (1) – 63.0 mm

(2.480") in this case – against fence (2).

• Release spindle clamp and move spindle

towards fence until spindle ring can just be

moved.

• Set lower indicator to basic setting of 63.0 mm

(2.480") (see page 4-1).

Pressure elements before and after

tool

• Set pressure elements after tool in relation to

tool with the aid of the setting straight edge.

• Then set pressure elements before tool so that

they are 3 mm (0.125") in front of the tool.

When the basic settings have been made for the

spindle and pressure elements, the entire assem-

bly must be set to the required workpiece width.

(B)

(5)

(5)

(A)

Ø 40

63

20

(1)

(2)

(3)

(0.125")

Loading...

Loading...