Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Data, transport, start-up

8-10 Profimat 23 E

Connection, start-up

Electrical connections

The machine may only be connected to the

plant mains power supply by a duly qualified

electrician familiar with the local regulations.

Risk of accidents due to electric power. When

working on electrical equipment, incorrect or

faulty connections can lead to damage due to

short-circuiting, as well as causing damage to

electronic components.

Connect wiring as indicated in circuit diagram

and on rating plate in control cabinet.

• Run power cable through opening provided in

the control cabinet.

• The phases may only be reversed at the main

connection.

• Check that all contact screws are secure before

switching on the master switch.

• If necessary, route power supply to the

matching transformer and then into the control

cabinet.

• Check direction of rotation of feed rollers in

order to verify that connections are correct.

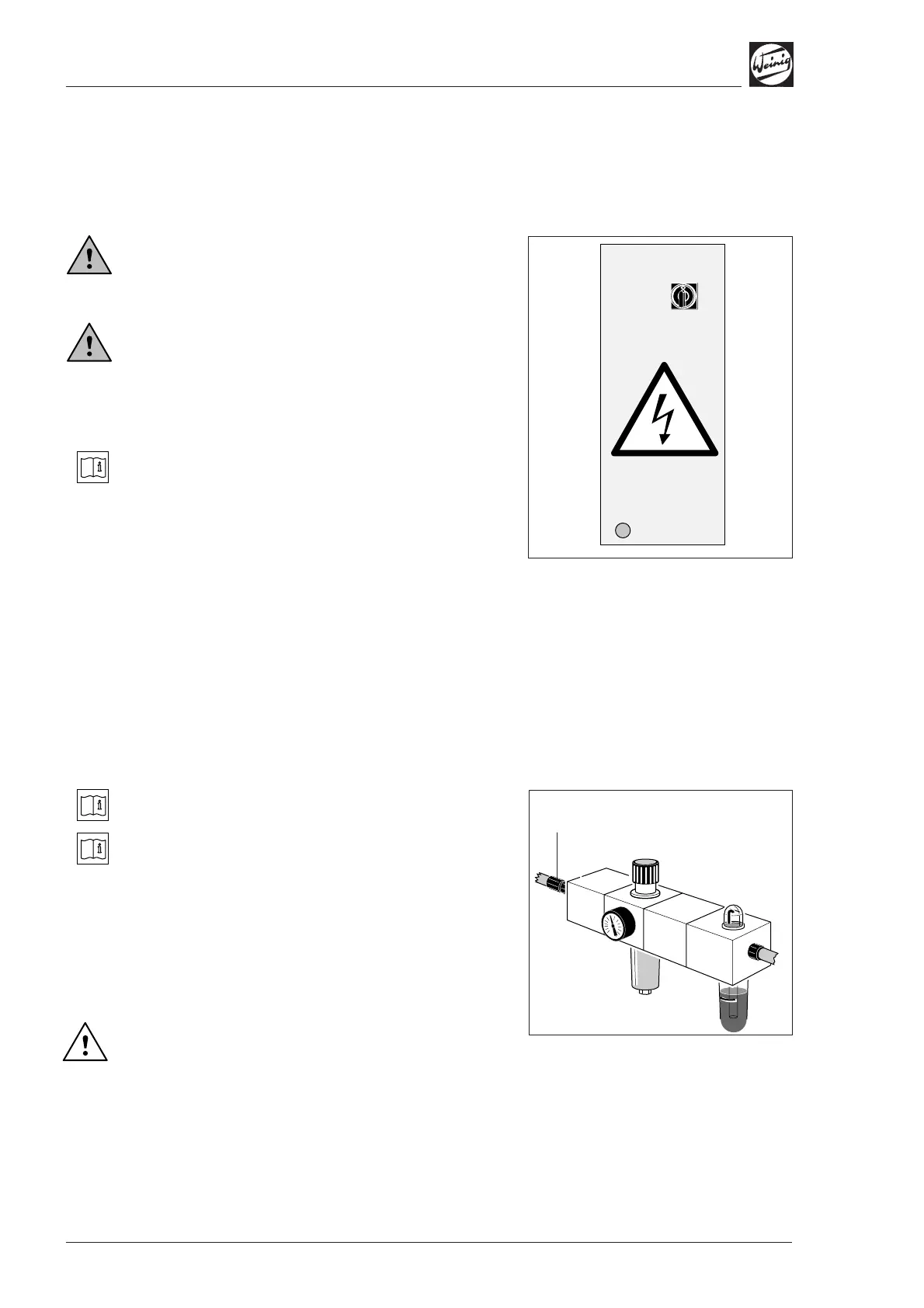

Pneumatic connection

Refer to the installation diagram with regard to

min./max. plant air pressure.

Refer to the installation diagram with regard to

the position of the pneumatic service unit.

• Connect compressed air hose to the pneumatic

service unit with the single-hand coupling (1).

(Note: Different service units are installed,

depending on the machine version concerned.)

• Set operating pressure (see technical data) on

the pressure reducer.

Only use dry, filtered and oiled compressed

air.

(1)

Loading...

Loading...